The diagram below displays Upstream. Critical components displayed in green.

The diagram below displays Downstream. Critical components displayed in green.

Pressure Control Overview

Pressure control in a vacuum system is a method by which the system pressure is maintained at a specific, often critical, point to perform a certain process or experiment. Pressure control is generally achieved through either upstream or downstream pressure control, or a combination of both methods. Throughout the industry, the usage of the terms "upstream" and "downstream" can vary among companies due how they view their process. To minimize confusion, we will think of upstream pressure control as the metered input of gas into the system and downstream pressure control as the throttling of flow through the pumping system. Automated upstream pressure control is typically achieved by use of a mass flow controller (MFC) while automated downstream control utilizes motorized throttling valves. Please note that these descriptions, as well as the details below, are summarized to reduce confusion and to provide a basic overview of pressure control. For further information, please contact us or visit our Tech Notes section.

A means of controlling the pressure in the system where the pumping speed is the variable component, usually controlled by a throttle valve between the turbo pump and chamber.

Control Valves - Critical ComponentThe motorized control valve is the heart of downstream pressure control. Butterfly valves are the most common valve type, but gate, right angle, and pendulum valves are available. The valve will be placed downstream of the process just in front of the high vacuum pump. During the process, the valve controller will communicate and interpret the output voltage from the capacitance manometer. If the pressure isn't correct, the valve will shutter between degrees of partially opened/closed. As the valve varies its position, the restriction to the pump and therefore the pumping speed of the turbo pump is affected. If the pressure is too high, the valve will open further to increase pumping speed and lower pressure, while the valve will move towards its closed position if the pressure is below the controllers setpoint. For a more in-depth view of the Throttle Valves, please contact valves@lesker.com.

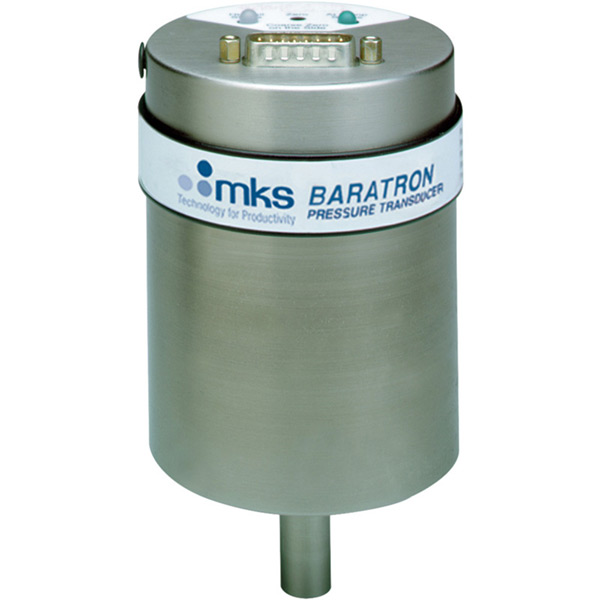

Capacitance Manometer - Critical ComponentA capacitance manometer is the gauge of choice for control pressure due to the high accuracy (typically 0.25%), fast response time (typically 100 ms), and gas independent properties. During the process, the capacitance manometer measures the pressure you are looking to control. This pressure, generally in the form of an output voltage, will be supplied to the controller at a constant frequency. If the current pressure varies from the setpoint control pressure, the throttle valve will adjust the degree of partially opened/closed, which will adjust the pressure. Please note that these units come in two flavors, ambient or heated. If you have nasty gases in the system or heavily deposit materials, a heated unit is internally heated to a set temperature and helps minimize condensation within the gauge. For a more in-depth view of Capacitance Manometers, please contact gauging@lesker.com.

Wide-Range (Combination) Gauges (WRG)A wide range gauge Is a key feature in the pressure control process, as this provides the first step: measuring the base pressure. In some processes, the user will need to reach a base pressure of 10-6 or lower to ensure that certain gases, like O2, are removed (mostly) from system. After the base pressure is reached, the user may input gas at a static (constant) rate to raise the pressure and control the gas composition in the system. At this point, the WRG may be turned off or isolated so it is protected from the process. Please note that the WRG’s can be single port or Multiport. The single port units are where multiple technologies are within one housing where Multiport units have the technologies separated. For a more in-depth view of Wide Range Gauges, please contact gauging@lesker.com.

- Compare common Wide Range Combination Gauges

- Compare common Cold Cathode / Hot Filament Gauges

- Compare common Convection Enhanced Pirani Gauges

Just like the valves in upstream pressure control, the MFC's can be used to downstream pressure control but usually are stationary. They are generally set for a constant flow rate and do not automatically change. For a more in-depth view of Mass Flow Controllers, please contact gauging@lesker.com.

Pump PackagesFor pump packages, contact pumps@lesker.com

A means of controlling the pressure in the system where the gas flow into the chamber, usually controlled by an MFC, is the variable component.

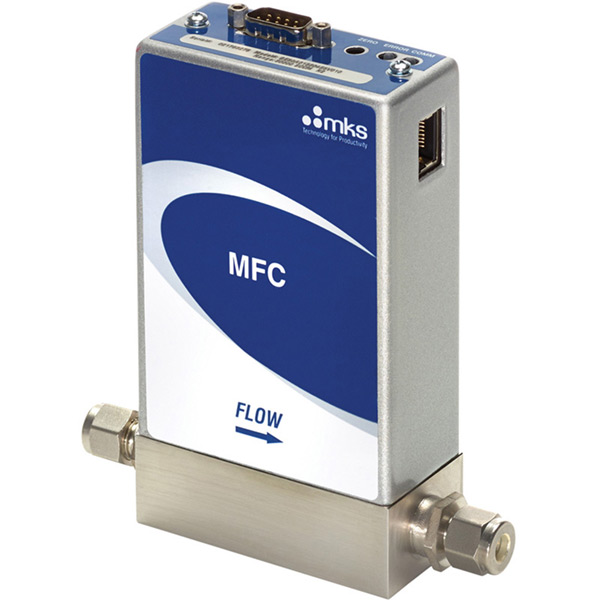

Mass Flow Controllers & Meters (MFC) - Critical ComponentDuring pressure control, the MFC will inject gas at a specific rate, while also communicating with the controller. If the incorrect output voltage is received from the controller (meaning that the pressure isnt correct), the MFC will adjust the flow rate. If the pressure is too high, the MFC will reduce the flow rate and if the pressure is too high, the MFC will increase the flow rate. For a more in-depth view of Mass Flow Controllers, please contact gauging@lesker.com.

Capacitance Manometer - Critical ComponentA capacitance manometer is the gauge of choice for control pressure due to the high accuracy (typically 0.25%), fast response time (typically 100 ms), and gas independent properties. During the process, the capacitance manometer measures the pressure you are looking to control. This pressure, generally in the form of an output voltage, will be supplied to the controller at a constant frequency. If the current pressure varies from the setpoint control pressure, the throttle valve will adjust the degree of partially opened/closed, which will adjust the pressure. Please note that these units come in two flavors, ambient or heated. If you have nasty gases in the system or heavily deposit materials, a heated unit is internally heated to a set temperature and helps minimize condensation within the gauge. For a more in-depth view of Capacitance Manometers, please contact gauging@lesker.com.

Wide-Range (Combination) Gauges (WRG)A wide range gauge Is a key feature in the pressure control process, as this provides the first step: measuring the base pressure. In some processes, the user will need to reach a base pressure of 10-6 or lower to ensure that certain gases, like O2, are removed (mostly) from system. After the base pressure is reached, the user may input gas at a static (constant) rate to raise the pressure and control the gas composition in the system. At this point, the WRG may be turned off or isolated so it is protected from the process. Please note that the WRG’s can be single port or Multiport. The single port units are where multiple technologies are within one housing where Multiport units have the technologies separated. For a more in-depth view of Wide Range Gauges, please contact gauging@lesker.com.

- Compare common Wide Range Combination Gauges

- Compare common Cold Cathode / Hot Filament Gauges

- Compare common Convection Enhanced Pirani Gauges

During pure upstream pressure control, a valve may still be utilized in front of the high vacuum pump to isolate the pump or reduce the pumping speed. If a valve is used, it will remain at a constant position, generally a point between full open and full close. Typically, a 3-position valve is used in this scenario. For a more in-depth view of Control Valves, please contact valves@lesker.com.

- 1e-9 to 760 Torr

- Multi-port Hot Filament / Pirani

- Integrated electronics / Integrated Display

- Controllers 2x Convection Gauges

- Replacement filaments available

- Built-in Analog and RS485 communications

- 7.6e-10 to 760 Torr

- Single-port Cold cathode / Pirani

- Integrated electronics / No Display

- High or low current options

- Replacement kits available

- 1e-9 to 760 Torr

- Single-port Hot Filament / Pirani / Piezo

- Integrated electronics / Optional Display

- Replacement filaments available

- Optional RS485 or DeviceNet serial communications

- 1e-9 to 5e-2 Torr

- Integrated electronics / Built-in Display

- Replacement filaments available

- Selectable calibration gauges for sustained accuracy

- 1e-9 to 5e-2 Torr

- Integrated electronics / No dispaly

- Replacement filaments available

- Compatible with KJLC MGC controllers or other PLC's

- 3.75e-4 to 760 Torr

- Compact design

- Replacement sensors available

- Tungsten or Nickel Filaments

- Optional Setpoints

- 250ºC bakeable version

- 1e-5 to 1000 Torr

- Optional Display

- MEMs Technology

- Compact Design

- Repair Kits available

- 1e-4 to 1000 Torr

- Passive; controller needed

- MKS Granville-Phillips 275 drop-in replacement

- Elastomer Sealed

- 5 to 50,000 sccm F.S. options

- Multi-Gas, Multi-Flow

- Integrated Software

- Metal Sealed

- 5 to 50,000 sccm F.S. options

- Multi-Gas, Multi-Flow

- Integrated Software

- Elastomer Sealed

- 5 to 50,000 sccm F.S. options

- Multi-Gas, Multi-Flow

- Integrated Software

- Integrated positive shut-off valve

- Metal Sealed

- 50 slm to 100 slm F.S. options

- Multi-Gas, Multi-Flow

- Integrated Software

- Elastomer Sealed

- 100 slm to 250 smlm F.S. options

- Multi-Gas, Multi-Flow

- Integrated Software

- Elastomer Sealed

- 5 sccm to 20,000 sccm F.S. options

- Single-Gas, Multi-Flow

- Cost Effective

- Ambient and Heated Options

- Absolute Measurement

- 0.1 to 1000 Torr F.S. Selections

- Ceramic Diaphragm

- Analog and RS232

- 2 Set Points

- Ambient

- Absolute Measurement

- 1 to 1000 Torr F.S. Selections

- Inconel Diaphragm

- Analog

- Optional Set Points

- Heated: 45°C, 80°C, or 100°C

- Absolute Measurement

- 0.1 to 1000 Torr F.S. Selections

- Inconel Diaphragm

- Analog

- Optional Set Points

- Ambient

- Absolute Measurement

- 1 to 1000 Torr F.S. Selections

- Inconel Diaphragm

- Analog

- +/-15 VDC Power Requirement

- Heated: 45°C

- Absolute Measurement

- 0.02 to 1000 Torr F.S. Selections

- Inconel Diaphragm

- Analog

- +/-15 VDC Power Requirement

- Heated: 100°C

- Absolute Measurement

- 0.05 to 1000 Torr F.S. Selections

- Inconel Diaphragm

- Analog

- +/-15 VDC Power Requirement

- Ambient

- Absolute Measurement

- 1 to 1000 Torr F.S. Selections

- Inconel Diaphragm

- Analog

- Compact Design

- Ambient

- Absolute Measurement

- 10 to 1000 Torr F.S. Selections

- Ceramic Diaphragm

- Cost Effective Option

Simultaneous control and readout for up to six vacuum gauges and/or six mass flow controllers, and one select valve for ultimate versatility.

Fit rough, bypass, and forelines that require high conductance, low profile, rapid opening, and throttling action.

Field of application: Semiconductors, FPD / CVD systems and industrial processes.

Semiconductors, FPD and industrial processes, particularly CVD systems.

| Manufacturer | Technology | Model | Integrated Display | Integrated Software | PLC Control | 946 Control |

| Lesker | ||||||

| Convection Enhanced Pirani / Pirani | ||||||

| 275 | x | |||||

| 275i | x | x | ||||

| 300 | x | x | ||||

| Pirani | x | |||||

| Hot Filament | ||||||

| 351 | x | |||||

| 354 | x | x | ||||

| B-A Ion Gauge | x | |||||

| Cold Cathode | CCP | x | ||||

| Combination | ||||||

| 392 | x | x | ||||

| CCPG | x | |||||

| Capacitance Manometer | ||||||

| Carbon | x | x | ||||

| ACG - Ambient | x | x | ||||

| HCG - Heated | x | x | ||||

| MKS | ||||||

| Convection Enhanced Pirani / Pirani | 275 | x | ||||

| Cold Cathode | ||||||

| 423 | x | |||||

| 431 | ||||||

| Combination | 390 | x | x | |||

| Baratron | ||||||

| 626D - Ambient | x | x | ||||

| 722 - Ambient | x | x | ||||

| 627H - Heated | x | x | ||||

| 628H - Heated | x | x | ||||

| MFC's | ||||||

| G Series MFC's | x | x | x | |||

| I Series MFC's | x | x | x | |||

| 1179C | x | |||||

| VAT | Throttle Valves | 61.2 | x | x |

Do you have any questions? Click below to get in contact with one of our many experienced team members.

CONTACT US TODAY