MKS® GE250A Mass Flow Controller

Multi-gas/multi-range, elastomer sealed, mass flow controller for flow rates up to 250 slm

The GE250A can be ranged from 100 to 250 slm (N2 equivalent). The GE250 is available with either analog I/O or digital I/O utilizing the latest control algorithms for fast and repeatable response to set point.

Settling times of 1 to 2 seconds and setpoint accuracies below 1% of setpoint exceeds typical high flow mass flow controllers. Precise control is maintained down to 2% of the GE250A's configured Full Scale flow range. Multi-gas/multi-range capability and tight performance specifications for accuracy, control range, and transient response minimize flow controller inventory requirements.

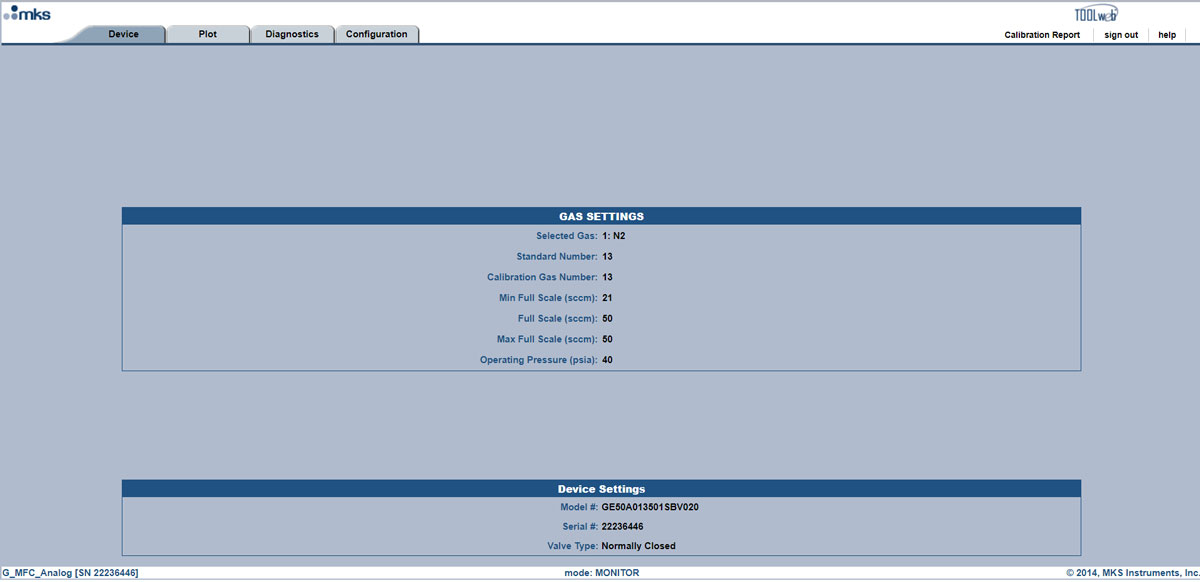

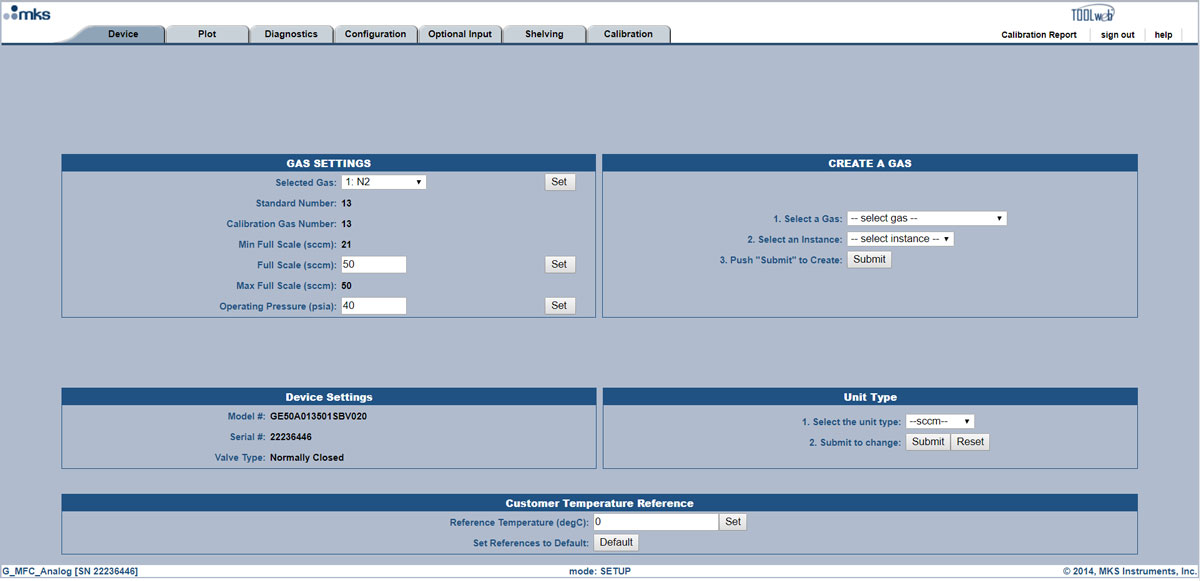

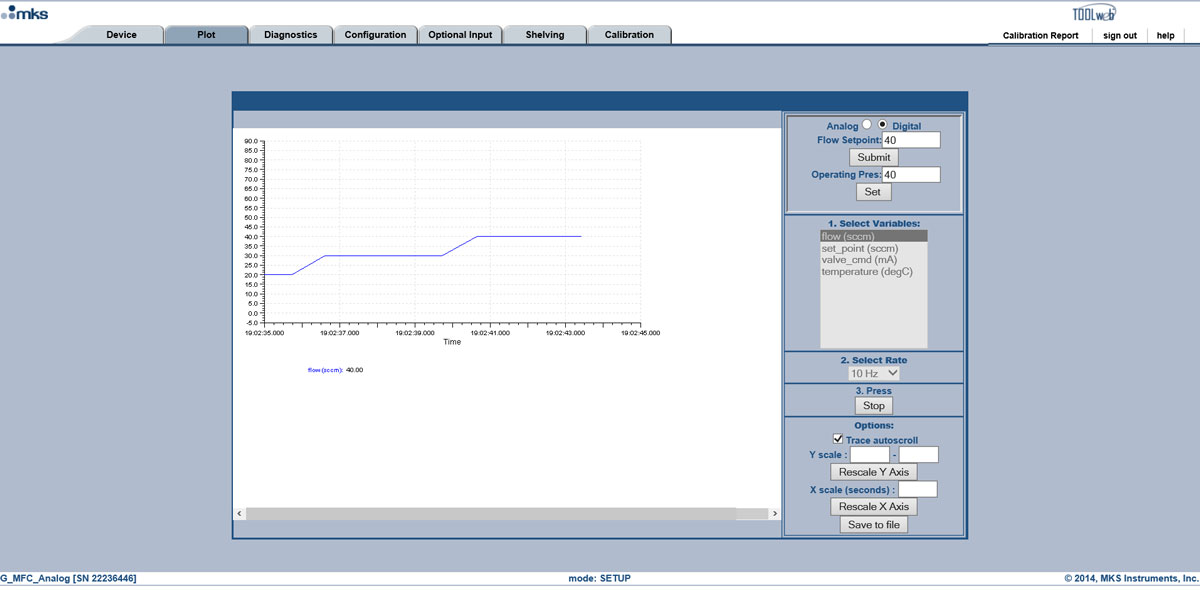

The multi-gas/multi-range feature and other custom controls are accessed through the embedded diagnostic interface. A standard Ethernet cable and JAVA-enabled HTML browser are the only tools needed. Critical gas parameters for typical high flow rate gases are already stored on the MFC. Configure an I-Series mass flow controller by selecting the gas from a drop-down menu and specify the desired Full Scale flow range. Perform routine device health checks, plot flow response, and store operating data for offline analysis with the I-Series MFC diagnostic interface.

Features & Benefits

- Fast response to setpoint change reduces flow stabilization time

- Tight flow accuracy improves process matching

- Reduced inlet pressure (pressure drop) requirement simplifies gas supply regulation

- Multi-Gas/Multi-range reduced MFC inventory

- Configuration/diagnostics via Ethernet & web browser - no special software needed

Applications

The GE250A mass flow controller is a general purpose, elastomer-sealed MFC suited for a wide variety of applications.

Specifications Table

| Model | GE250A |

|---|---|

| Input Power | +15 to +24 VDC @ (<4 watts) |

| Full Scale Flow Ranges | 100 - 250 slm (N2 equivalent) |

| Maximum Inlet Pressure | 150 psig (cannot exceed pressure differential requirement across MFC) |

| Normal Operating Pressure Differential | 30 to 55 psid (dependent on fitting type) (with atmospheric pressure at the MFC outlet) |

| Burst Pressure | 1500 psig |

| Control Range | 2% to 100% of Full Scale (range on mech.) |

| Typical Accuracy | ±1% of set point for >20% to 100% Full Scale ± 0.25% of Full Scale for 5% to 20% Full Scale |

| Repeatability | ± 0.5% of Reading |

| Resolution | 0.1% of Reading |

| Typical Controller Settling Time | 1 to 2 seconds typical above 10% Full Scale @ 50 psi |

| Warm-up Time | one (1) hour |

| Operating Temperature Range | 10°C to 50°C (Ambient) |

| Storage Humidity | 0 to 95% Relative Humidity, non-condensing |

| Storage Temperature | -20° to 65°C (-4° to 149° F) |

| Leak Integrity - External | <1 x 10-9 (scc/sec He) |

| Leak Integrity - Through Closed Valve | <1.0% Full Scale at 40 psia to vac (<500 mTorr) (To assure no flow-through, a separate positive shut-off valve is required.) |

| Flow Input/Output Signal - Voltage | (0 to 5 VDC) 15-pin Type "D" male |

| Flow Input/Output Signal - Current | (4 to 20 mA) 15-pin Type "D" male |

Configuration Options

Ordering Code Example: GE250A013255TBV0020

| Series | Code | Configuration |

| Type MFC High Flow Mass Flow Controller (multigas, multi-range) | GE250A | GE250A |

| Gas (Per Semi Standard E52-0703) | Code | Configuration |

| 013 = Nitrogen = N2 | 013 | 013 |

| Flow Range Full Scale* | Code | Configuration |

| 250,000 sccm (250 slm) | 255 | 255 |

| Fittings (compatible with) | Code | Configuration |

| 12mm Swagelok® | F | T |

| 3/8" Swagelok® | J | |

| 1/2" tube compression | S | |

| 1/2" Compression Long | W | |

| 1/2" NPT female | M | |

| 8 VCR Male | T | |

| 8 VCO Male | D | |

| 8 VCR Male Long | L | |

| 8 VCO Male Long | Q | |

| W-Seal | H | |

| Connector (Power & Control I/O) | Code | Configuration |

| EtherCAT® | 8 | B |

| DeviceNet™ | 6 | |

| RS485 (uses 9 pin connector) | 5 | |

| Profibus® | 4 | |

| 15 pin D (Analog 0 to 5 VDC I/O) | B | |

| 15 pin D (4 to 20 mA I/O) | G | |

| Seal Materials | Code | Configuration |

| Viton | V | V |

| Buna-N | B | |

| Neoprene | N | |

| EPDM | E | |

| Valve Type | Code | Configuration |

| Normally Closed | 0 | 0 |

| Meter | 3 | |

| Reserved for MKS Future Use | Code | Configuration |

| Standard | 0 | 0 |

| Firmware | Code | Configuration |

| Unless otherwise specified, MKS will ship firmware revision current to date | 20 | 20 |

* The Full Scale flow rate is designated by a 3 digit number. The first two digits represent the significant digits of the Full Scale flow rate separated by a decimal point. The third digit is the exponent of the power of ten.

Included Software

Free, downloadable software that allows for simple monitoring and configurations of the MKS MFC.

Features and Benefits

- Easy to use interface

- Ability to switch between a library of over 150 different gases

- Can plot and record the flow data

- Downloadable calibration report for the MFC unit

For further details, please reference the Software User Manual.

To record data using the plotting tool, please contact us by clicking here for the Java Policy update.

Remote Controllers

The MKS Instruments 246 single channel/readout is designed to control and display most MKS flow transducers. If multiple channels are required, the MKS Instruments 247 controller provides a four channel, sequentially selectable readout. The flow rate set point can be adjusted either through front panel controls or remotely through the rear panel analog interface. The unit supplies ±15 VDC power.

Features and Benefits:

- Power and control between 1 - 4 MFC units.

- Compatible with most MKS MFC units.

- Standalone controllers

946 Vacuum System Controller

Versatile vacuum controller that supports a wide variety of pressure sensors, MFC's, and valves for system control.

Features and Benefits:

- Simultaneous control and readout for up to six MFC's and/or vacuum gauges

- Closed-loop pressure control option for use with MKS valves eliminates the need for separate pressure control electronics

- Pressure readings from 1,000 Torr down to 10-11 Torr, eliminating the need for individual electronics for each sensor

- 12 set point relays included in the base unit for system control flexibility

- Standalone controller

PAC 100

Configurable and expandable module that can allow for full system control.

Features and Benefits:

- Allows for continual module expansion for increased workload

- Access to Control Workbench software to monitor, record, and control all connected devices

- Compatible with MKS MFC's, direct and indirect gauging, valves, etc.

- Controlled through a PLC

- Low cost of ownership

| Power Supply and Readouts | MFC Software | 246 Power Supply and Display | 247 Power Supply and Display | 946 Vacuum System Controller | PAC 100 Automation System |

| Display Type | PC (not included) | 3 1/2 digit 0.56" red LED, continuous display | 3 1/2 digit 0.56" red LED, display is 1 of 4 sequentially selectable | 320x240 color QVGA TFT LCD with back lighting. Up to 6 pressure or flow displays. Display indicators for unit of measure, calibration functions, user calibration, set points, PID control status and valve position. | PC (not included) |

| Channels | 1 MFC | 1 MFC | 4 MFC's | 6 of any combination below. MKS MFC's*MKS Baratrons*, MKS Piranis*, MKS Convectron/Convection Series*, MKS Hot and Cold Cathode Sensors*, MKS Pressure Control Valves* |

4 of any combination below. MKS MFC's*, MKS Baratrons* **Other modules available |

| Setpoint Relays | Yes | No | No | Yes | Yes |

| Power Input | N/A | 117/234 VAC ±15%, 50-60 Hz | 117/234 VAC ±15%, 50-60 Hz | 150 watts maximum 100 - 240 VAC 50/60 Hz | 19VDC - 32VDC, Max - 5A (each for DC I/O and DC CORE) |

| Approximate List Price | Free (included with MFC purchase) | $1225 (interface cable not included) | $1850 (interface cable not included) | $1814 to $5877 (region specific power cable included) (interface cables not included) | $1740 (interface cables not included) |

Start Your Configuration

Accessories Table

| Description | Reference | Part Number | Price | In Stock | Add Item | |

|---|---|---|---|---|---|---|

| Description | Reference | Part Number | Price | In Stock | Add Item | |

|

NON RoHS/ CE, |

246C Single Channel Display, Power Supply / Readout |

|

|

|

||

|

NON RoHS/ CE, |

247D 4 Channel Sequential Display, Power Supply / Readout |

|

|

|

||

|

CABLE, |

Wall Transformer, 15 pin, 4.5 ft., Universal Plug Ends |

|

|

|

||

|

CABLE, |

15 Pin Sub-D 3-meter cable |

|

|

|

||

|

CABLE, |

9 Pin Sub-D 3-meter cable |

|

|

|