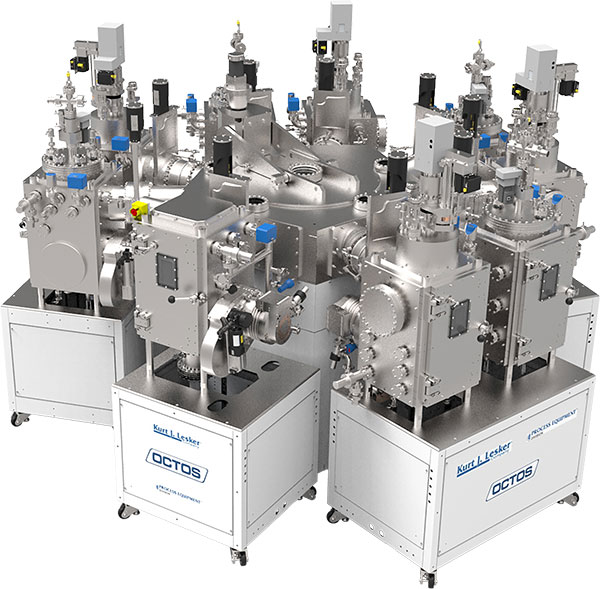

KDF In-Line Solutions

We offer the most advanced and reliable physical vapor deposition batch in-line sputtering tools at the industry's lowest cost of ownership. KDF systems can be customized to meet the customer's needs and cover a wide variety of process requirements for the mainstream silicon, emerging materials and flat panel display markets. The complete line of KDF equipment has been redesigned and improved to meet today's critical applications.

600i Series Vertical Batch-Sputtering SystemThe 600i Series features dual load lock, in-line, RF / DC side sputtering batch systems.

They are configured with an optional high vacuum load lock and three or four target positions and have a 13 x 13-inch pallet size. (Unique pallet designs available).

- Vertical side sputtering systems.

- 13" x 13" pallet size.

- Small footprint.

- Dual-process loadlock.

- Optional Robot designed for particulate-free, reliable cassette to cassette substrate handling operations.

- Multiple bias types enable denser films and planarization.

- Multi-size capability enables rapid change from one substrate to another; substrate size can be changed run to run (pallet based).

- Optional integrated RGA for process and fault monitoring of gas peaks along with integrated hivac step.

- New in situ pallet optical measurement hardware with integrated software allowing operators to program and control actual pallet temperature.

744i Vertical Batch-Sputtering SystemThe 744i is a large area, four-target, RF/DC batch-sputtering system, designed for processing high-density interconnect, 200mm semiconductor wafers and flat panel displays.

The 744i will accommodate glass sizes up to Gen 2. The 744i is equipped with a high-vacuum load lock configured with a substrate pre-heat that enables the tool's high throughput. The 744i offers a pallet area of 19 x 19 inches with a compact footprint that uses less than one-third the floor space of competing equipment.

- Broad Spectrum Research Tools

- Large Area Production Tools [Gen 2]

- Custom System Designs

- In House Full Metrology for Process Development

- Lowest Cost of Ownership with Superior Uptime

- R&D and Production Custom Cluster Tools

844i Series Vertical Batch-Sputtering SystemThe 844i series is a large area, four-target, RF / DC batch sputtering system designed for processing high-density interconnect, 300mm semiconductor wafers, solar photovoltaic cells and flat panel displays.

The 844i will accommodate glass sizes up to Gen 3. Because of its size the 844i system is an extremely cost effective way of running batches of small to large wafers or substrates.

- Vertical side sputtering system.

- 26.5" x 30" pallet size.

- Compact footprint that uses less than one third of the space required for competing equipment.

- Dual-process high-vacuum loadlock.

- Capacity to process up to four 300 mm wafers or multiple smaller wafers at once.

- Throughput for 300 mm wafer metallurgy is increased four times over that of a 600i Series system.

- Glass sizes up to Gen 3.5.

- Pallet assist tool (PAT) for handling up to 100 lb pallet payloads in a safe and repeatable manner.

- Through the wall design allows for clean room compatibility.

- Optional Robot designed for particulate-free, reliable cassette to cassette substrate handling operations.

900i Series Horizontal Batch-Sputtering SystemThe 900i Series features dual load lock, in-line, sputter down, batch systems configured with an optional high vacuum load lock and three or four target positions.

High-rate DC magnetron sputtering, single pass or multiple pass deposition and dual-level high vacuum pumped load lock features support the versatility and high-throughput of these production systems. Cathode and wafer orientation are horizontal, allowing the sputtered material to be transferred vertically.

- Horizontal cathode and substrate orientation for gentle substrate fixturing and varied substrate sizes.

- 12" x 12" substrate area.

- Capacity to process dimensional substrates up to 1.5" thick.

- Optional hardware allows for 2" thick substrates.

- High-rate DC magnetron sputtering and single/multiple-pass deposition features.

- Capacity to process up to one 300 mm wafer or multiple smaller wafers at a time.

- Convenient wafer to pallet loading ability.

- Optional high vacuum loadlock configuration with quartz heater lamps for efficient degassing of substrates.

- Optional planetary substrate pallet for unsurpassed film uniformity.

- Optional integrated RGA for process fault monitoring of gas peaks along with integrated hi vac step.