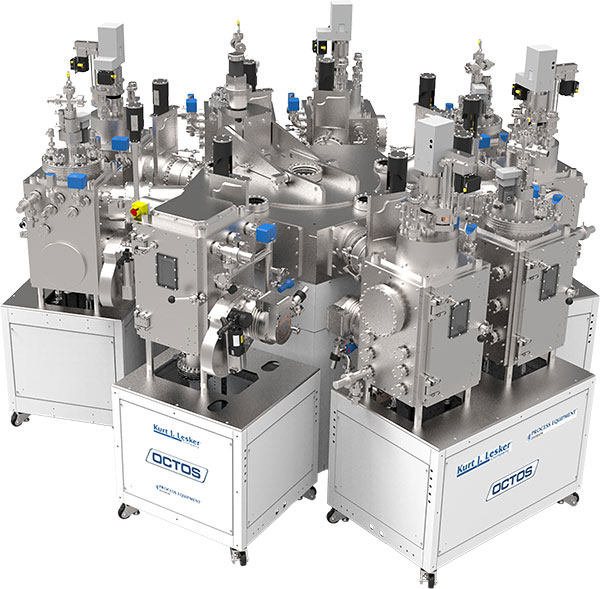

844i Series Vertical Batch-Sputtering System

The 844i will accommodate glass sizes up to Gen 3. Because of its size the 844i system is an extremely cost effective way of running batches of small to large wafers or substrates.

Overview

The 844i is equipped with a high-vacuum load lock configured with a substrate pre-heat that enables the tool's high throughput. The 844i offers a pallet area of 26.5 x 30 inches with a compact footprint that uses less than one-third the floor space of competing equipment. The tool can hold four 300mm wafers or multiple smaller wafers and features two processing pallets, allowing an instantaneous change of wafer sizes and the ability to process both the front and backsides of wafers.

Specifications

Vacuum Specifications

- Chamber ultimate, < 9.0 x 10-8 torr.

- High vacuum dome leak rate, 15 minutes to 1 x 10-4 torr.

- Pump down from atmosphere 110 minutes or less to 1 x 10-6 torr or 1.0 x 10-7 torr overnight.

Orientation

- Vertical

Deposition Zone

- 26.5" x 30" pallet size

| SYSTEM CAPACITY | |||||||

|---|---|---|---|---|---|---|---|

| 844i PALLET 26.5" x 30" | 2" Wafers | 3" Wafers | 4" Wafers | 5" Wafers | 6" Wafers | 8" Wafers | 300mm |

| 153 | 72 | 42 | 25 | 16 | 9 | 4 | |

Series System Hardware Features

- 20kW low stored energy DC power supplies (Advanced Energy).

- Integrated dual throttling SS VAT valves allowing for upstream or downstream gas pressure control.

- MKS multi component "Smart" 390 and 925 gauges for integrated vacuum measurement.

- Process gas control with up to four gas controllers; feedback controlled capacitance manometer; master/slave gas select ability; and gas ratio control.

- Stepper motor pallet carrier and shutter drive with optical encoder providing accurate programmable pallet carrier shutter positioning, scan velocity profiling available.

- Low pressure hydraulics system for safety and smooth operation.

- Loadlock linear sensor - computer controlled positioning system for increased loadlock accuracy and more limited fail safe.

- Fully shielded chamber allowing for faster chamber cleaning and less clean room contamination.

- Stepper driven automated Load lock door.

- Complies with NFPA79 guidelines.

- Consult factory for an extensive list of standard options.

Series Computer Sub-System

- Windows™ 10 based real-time GUI environment, coupled with 24" LCD touchscreen monitor mounted on an umbilicaled mobile HI cart.

- Context sensitive recipe manger running out of Microsoft® SQL database.

- Fully integrated package for real-time data display, data logging fully compatible with Excel™, Lotus™ and other Windows™ applications, report generation, remote interface and printing.

- Optional connectivity to SECS/GEM communication and WindowsOptional connectivity to SECS/GEM communication and Windows™ applications through and OPC server interface. applications through and OPC server interface.

- Distributed Rockwell Control System utilizing Device Net and Ethernet IP field bus technologies

- Maintenance test suite with full diagnostic and manual process control capability.

- Service friendly fully enclosed electronic cabinet.

Series Basic Facility Requirements

- Power: 208 VAC, 3-phase, 225 Amps

- Water: 8 GPM, 70 PSIG min., 10°C - 24°C

- Compressed Air: 85 - 100 PSIG

- Process Gas: 25 PSIG 99.999%

- Pure Gas: Dry N2

Production Targets Fitted for KDF Systems

We provide all configurations of targets and bonded assemblies for the 600, 700, 800 and 900 series KDF systems. As the system manufacturer, we are uniquely positioned to provide targets which perform at the highest level and meet the unique design requirements of the KDF sputtering systems.

Target materials will be provided in the correct configuration for the most demanding of applications - From R&D to high volume production.

Production techniques include:

- Vacuum induction melting

- Hot pressing

- Hot isostatic pressing

- Electron beam melting

- Sintering

All targets will be inspected, cleaned and package for use as received. Special inspection, labeling and packaging can implemented upon request. Products will undergo thorough quality checks of the dimensions, purity and other required specifications.

An SDS in the specified language and Certificate of Analysis will accompany each target. All products are responsibly sourced and Conflict Minerals free. DFARs and ITAR compliant products are available upon request.

Mu Configuration

- 4 Piece & Single Piece Designs

- 15", 17", 24" & 30" Lengths

- Common Materials: Ti, TiW, NiCr, NiV, Ta, Nb, Cr, Al, W, Mo, Ag, Ru - Others available upon request

Upsilon Configuration

- 4 Piece Design

- 15", 17" & 24" Lengths

- Common Materials: Au, Pt, Pd - Others available upon request

Chi Configuration

- 4 Piece & Single Piece Designs

- 15" & 17" Lengths

- Common Materials: Al, Al alloys, Cu

Standard Planar Configuration - Bonded Assembly

- Single or Multi-tile Design

- 15", 17" NTX & 24" Lengths

- Common Materials: Au, Pt, Al, Al alloys, Ti, TiW, Ni, Co, NiCr, NiV, Ta, Nb, Cr, W, Mo, Ag, Ru, Si - Others available upon request

3" X 17" Cathode

- Single or Multi-tile Design

- Common Materials: Au, Pt, Al, Al alloys, Ti, TiW, Ni, Co, NiCr, NiV, Ta, Nb, Cr, W, Mo, Ag, Ru, Si - Others available upon request