February 13, 2025 | By KJLC Blog

The Kurt J. Lesker Company is proud to announce the release of its latest publication, Fundamentals of Vacuum Science Volume 1. This comprehensive guide is an essential resource for anyone interested in the principles and applications of vacuum science and system design for high and ultrahigh vacuum environments.

Read More

Tags:

Systems

Vacuum Science

Deposition Techniques

News

January 08, 2025 | By KJLC Innovate

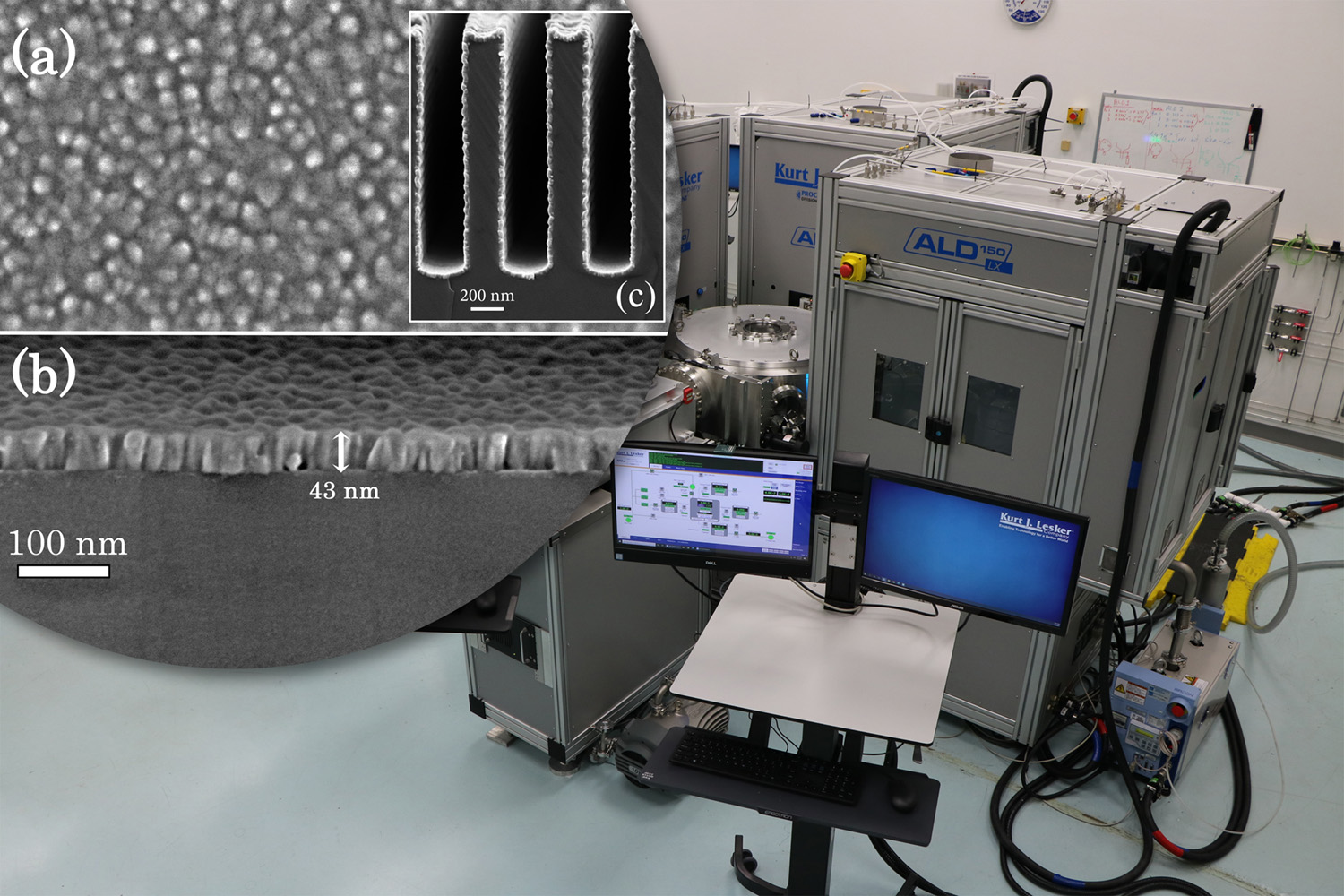

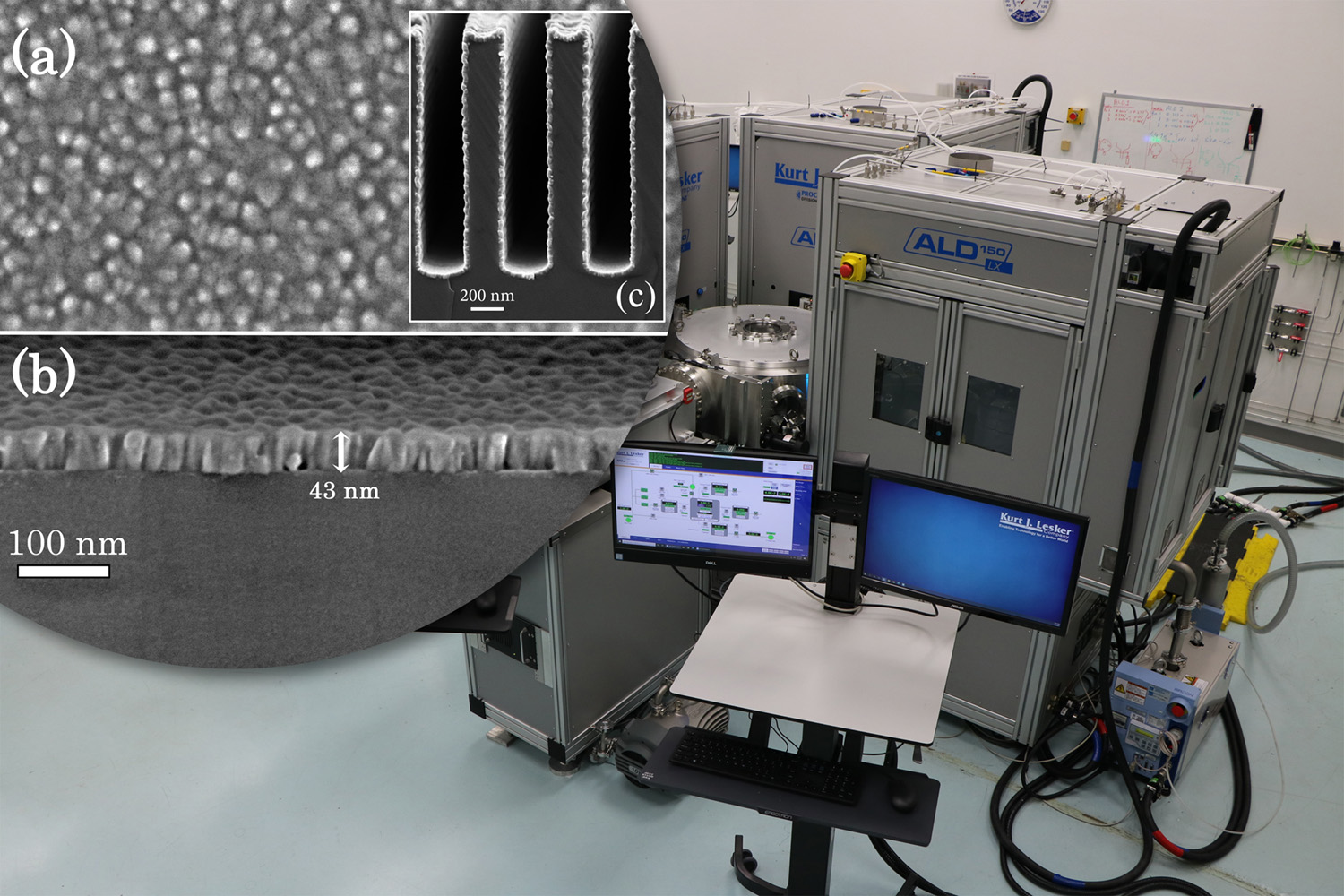

In the ever-evolving world of semiconductor technology, innovation is the key to staying ahead. At Kurt J. Lesker Company, we are proud to announce a groundbreaking achievement that promises to revolutionize the field of Atomic Layer Deposition (ALD). Our latest publication, featuring the patented Precursor Focusing Technique (PFT) and Ultra-High Purity (UHP) process capability, marks a significant milestone in our commitment to advancing next-generation applications.

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Deposition Techniques

July 29, 2024 | By KJLC Innovate

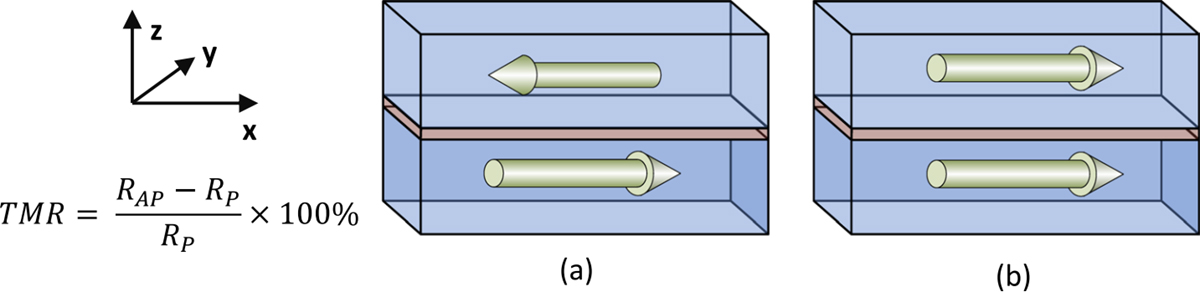

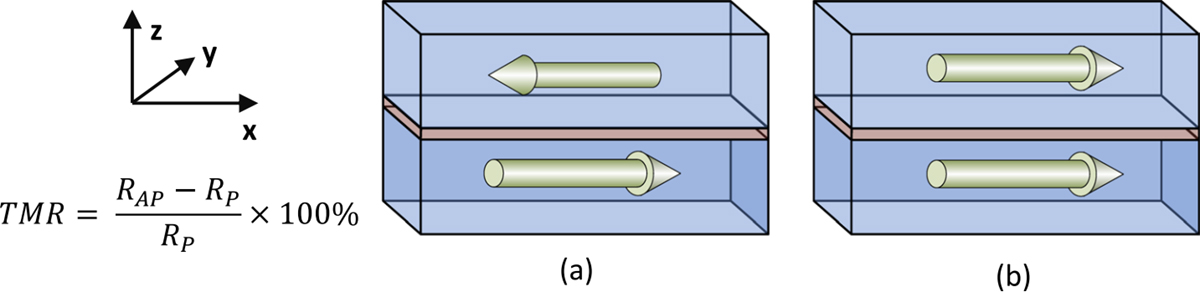

Nanoscale magnetic tunnel junctions (MTJs) are set to revolutionize high-density memory storage. These advanced nanostructures, composed of two ferromagnetic layers separated by an insulating barrier, utilize quantum mechanical tunneling to read and write data efficiently. Their ability to maintain data integrity even at extremely small scales makes them ideal for next-generation memory technologies like Magnetic Random Access Memory (MRAM)...

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Deposition Techniques

June 11, 2024 | By KJLC Innovate

We are proud to announce a new development from our Process Equipment Division a Full Target Encapsulation (FTE) Shutter, focused on developing a magnetron shutter design that is both compact and effective in eliminating cross-contamination between sources. This dedication to innovation and customer satisfaction has led to the creation of a pioneering product that not only meets but exceeds performance expectations. That is why we are excited to announce a development in technical capabilities that significantly enhances the our magnetron shutter design, particularly in achieving near-zero cross-contamination.

Read More

Tags:

INNOVATE

Systems

October 24, 2023 | By KJLC Blog

The Kurt J. Lesker Company, has expanded the capabilities of its Pittsburgh thin film applications laboratory with the addition of a model KDF 603 pilot production thin film deposition system, from its newly acquired subsidiary, KDF Technologies. The addition of the KDF thin film deposition tool will enable our Pittsburgh-based experts to perform coating trials for new prospects while optimizing the 603 system with the addition of features including plasma emission monitoring – critical to reactive sputtering.

Read More

Tags:

Systems

Vacuum Science

Deposition Techniques

August 31, 2023 | By KJLC Blog

The United States is engaged in a colossal effort to reshoring critical semiconductor manufacturing technology in order to better insulate domestic demand from international supply chain instabilities. This will create thousands of new jobs, requiring a substantial expansion of the US workforce skilled in vacuum science and its application.

Read More

Tags:

Systems

Vacuum Science

Deposition Techniques

August 08, 2023 | By KJLC Innovate

JEFFERSON HILLS, PA, August 4, 2023 - Kurt J. Lesker Company (KJLC) has been granted a pivotal patent by the United States Patent Office. The patent, identified under US 11,631,571B2 dated April 18, 2023, focuses on the application of Ultra-High Purity (UHP) conditions to Atomic Layer Deposition (ALD) and Plasma-Enhanced ALD (PEALD) systems, offering significant advancements in atomic scale processing research and applications.

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Deposition Techniques

April 03, 2023 | By KJLC Blog

The Kurt J. Lesker Company's Process Equipment Division (PED) in EMEIA has been delivering Physical Vapor Deposition (PVD) equipment to customers in the region for more than 25 years, and we take great pride in supporting our customers with the remarkable research they do. Our ability to innovate is crucial to providing solutions to our thin film customers.

Read More

Tags:

Systems

Vacuum Science

Deposition Techniques

August 12, 2022 | By KJLC Blog

The Institute for Solar Energy Research in Hamelin (ISFH), Germany, recently added a Kurt J. Lesker Company NANO 36 evaporation tool to their Perovskite PV research lab. The glovebox integrated deposition system is equipped with two thermal evaporation sources for the deposition of electrical contacts and a corresponding adhesive layer.

Read More

Tags:

Systems

Vacuum Science

Deposition Techniques

July 20, 2022 | By KJLC Blog

A new PVD 200 e-beam and thermal deposition system was installed by us in the newly launched micro-and nano-fabrication facility at Nazarbayev University. Among other projects, the research group is working on the fabrication of various field-effect transistors (FETs), microwave kinetic inductance detectors (MKIDs) and other devices. The PVD 200 system will be used for metal lift-off processes and is equipped with an electron beam source and two thermal sources along with a load lock for fast processing. We're looking forward to hearing more about this project in the future!

Read More

Tags:

Systems

Vacuum Science

Deposition Techniques

Previous Entries