After an extended shut-down it may be time to re-start your Kurt Lesker built thin film deposition system. A detailed re-start procedure for systems equipped with our eKLipse control software can be found below. This procedure provides a detailed description of the steps required to safely return our deposition systems to full operation.

Procedure

Prior to the startup and operation of any tool/system equipment, the intended operator should review the specific Kurt J. Lesker system manual(s) and the individual component manuals.

- Ensure that all utilities are properly installed per Site Preparation Guide as found in the system manual.

- Please make sure all circuit breakers are turned off on the Power Distribution Unit (PDU).

- Turn on the main power disconnect to the tool.

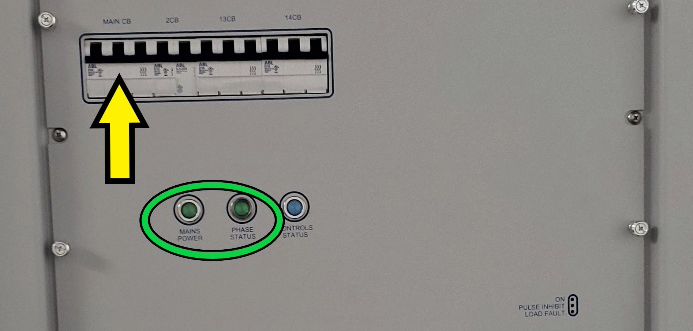

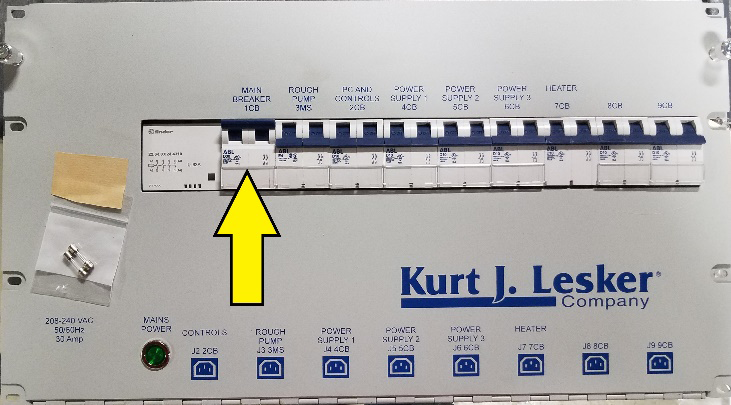

- Turn on the Main Circuit Breaker on the PDU (indicated with yellow arrow in pics below).

-

If system has a 3-phase PDU, please follow the steps below:

- Observe the three lights on the PDU. Two green lights should be on, Mains Power and Phase Status (green circle below).

- If the Phase Status light is off or not illuminated, turn off the Main Circuit Breaker on the PDU and the main power disconnect to the tool. Have a qualified electrician check the building power.

- Ensure all EMO buttons are disengaged. Then power on the remaining circuit breakers on PDU which are needed to run the various system components (this can be found in the electrical engineering prints found in the manual).

- Press the blue Start button on the front of the Rigel controller to engage the controls. The button should turn on blue as well as the last Controls Status indicator light on a 3-phase PDU.

- Power on the PC.

- Wait for the light tower on top of the control rack or the front of the Rigel controller to turn on, this verifies that the Rigel has successfully started and is communicating with the system I/O.

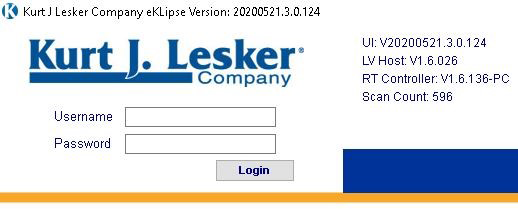

- Open the eKLipse software and log in with the proper credentials in the top left corner (see pic below)

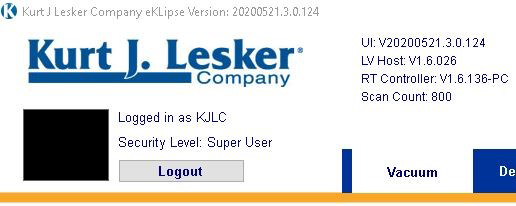

- Once logged in, the credentials box will change (see pic below) and the user will now have access to software controls depending on user level and permissions.

NOTE: The User Level will vary according to logged in user. Not every User Level has access to all software features. If a user attempts to access a restricted software feature, an error message will appear. See System Users Screen for User Level designations.

To bring chamber under vacuum, follow the steps below:

For a Turbo Pump

- Verify the proper air and gas connections are made and correct pressures are set at regulator. (see -0100 drawing). Typically 80 psi compressed air and 10 psi nitrogen vent.

- If applicable, verify cooling water is on to turbo pump and/or turbo pump has oil in it.

- Verify chamber is in a safe state to begin pump down; no loose foil or components in chamber.

- On the right hand side of the software, click on the PC Pump button to start the pump recipe.

For a Cryo Pump

- Verify the proper air and gas connections are made and correct pressures are set at regulator. (see -0100 drawing). Typically 80 psi compressed air, 10 psi nitrogen vent, 40 psi cryo purge.

- Verify cooling water is on to cryo compressor and/or any other liquid cooled pumping components.

- Verify chamber is in a safe state to begin pump down; no loose foil or components in chamber.

- If the cryo is off and warmed up, run a cryo regeneration cycle by selecting the PC Cryo Regen recipe from the command tab or run recipe list.

- Once the cryo pump has cooled to the proper temperature, on the right hand side of the software, click on the PC Pump button to start the pump recipe.

As always, if you have any questions about returning your system to service please reach out to your regional Lesker Sales Manager, or submit a question through one of our global system service department at locations:

North America, South America, & Australia

Phone: +1 412 387 9128

Fax: +1 412 384 2745

E-mail: NAservice@lesker.com

Europe, Middle East, India, & Africa

Phone: +44 1424 458100

Fax: +44 1424 458103

E-mail: EMEIAservice@lesker.com

Asia

Phone: +86 21 50115900

Fax: +86 21 50115863

E-mail: ASIAservice@lesker.com