In a recently issued patent (US 10,619,950 April 14, 2020) researchers at the Toyota Motor Company have demonstrated that the corrosion resistance of stainless steel exhaust systems for cars and trucks can be substantially improved by heat treatment in high vacuum. Stainless steel is a complex metal alloy of iron, nickel, chrome and other elements. It is known to be a very durable metal but even this robust material can be corroded by exposure to chloride ions, sulfuric and hydrochloric acids, soot and other artifacts of the exhaust from an internal combustion engine. Reaction with these aggressive gases causes pits in steel which eventually lead to premature failure. The use of low-grade fuels speeds the degradation of exhaust systems.

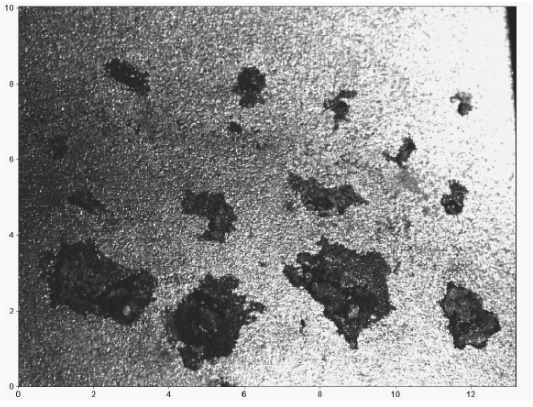

Fig. 1, Pitting in Stainless Steel caused by Sulfuric and Hydrochloric acids (Ref. 1)

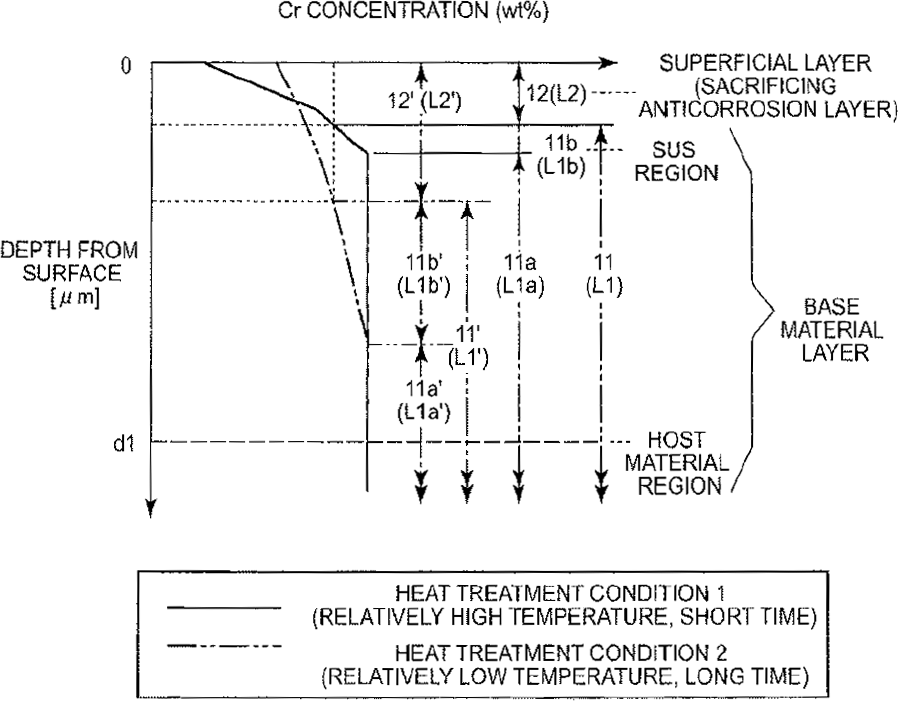

In the patent, the research team including Yu Takaezawa and others describe the modification of the surface of stainless steel using a process called dechromization that reduces the chrome content, typically about 17 wght % in alloy #316L, to less than 11% by vaporization. The chrome-starved surface then acts as a sacrificial layer when attacked by exhaust gases. The vacuum modified layer, with a thickness of several microns, endures the damage caused by exhaust gases thereby protecting the bulk of the metal from deterioration. There are several processes available designed to protect the surfaces of steel from degradation, including a variety of coatings, but those processes all add considerable cost. The newly patented process involves treating the automotive exhaust parts in vacuum at 10-2 Pa, or 7.5 x 10-5 Torr and heated to 1,100oC - 1,300oC,. The process is completely conformal and the thickness of the sacrificial layer can be easily controlled through modification of the time at temperature.

Fig 2. Reduction in chrome content of the outer layer of stainless steel exposed to high vacuum and temperature. (Ref. 2)

Stainless steel exhaust components for autos, trucks and motorcycles represent a $26 billion USD industry, world-wide, with modest growth expected in the post-pandemic economy (Ref. 3). The desire to increase the useful life of cars and trucks drives the need for the development of technologies that will increase the robustness of automotive wear components including exhaust systems. While the manufacturing of exhaust systems is now centralized in China, there are still significant manufacturing efforts in the Americas and Europe.

References

1. Pitting and Corrosion in the wet section of the automotive exhaust systems, C. Hoffmann et al., HTWG Konstanz University of Applied Science, Journal of Achievements in Materials and Manufacturing Engineering, Vol. 34, Issue 2, June 2009)

2. U.S Patent 10,619,950, April 14, 2020, Stainless Steel and Method of Manufacturing the Same, Assignee: Toyota Jidosha Kabushiki Kaisha (Toyota Motor Company)

3. Automotive Exhaust Systems Market by Component Type, Credence Research, October 2018, Report Code: 59373-10-18