Dr. Nicholas A. Strnad (General Technical Services, LLC) in collaboration with the U.S. Army Combat Capabilities Command Army Research Laboratory and the University of Maryland, College Park have recently developed conformal processes for a variety of lead-based electronic materials with outstanding properties using atomic layer deposition (ALD). The findings have been recently published in the Journal of Vacuum Sciences and Techology, A (ref. 1) and the Digital Repository at the University of Maryland (DRUM) (ref. 2). In particular, lead zirconate-titanate (PbZrxTi1-xO3, or PZT) is widely known to be the archetypal material for piezoelectricity (high electro-mechanical coupling coefficient) and ferroelectricity (large charge density per unit area). Correspondingly, PZT has several commercial applications ranging from ferroelectric random access memory (ref. 3) to ink-jet print heads (ref. 4) as well as emerging applications such as actuators in low-cost piezoelectric microelctromechanical systems (PiezoMEMS) (ref. 5). The new processes represent a radically new approach to depositing high-quality piezoelectrics, shifting the paradigm from traditionally 2D devices to 3D trenches, nano-pores, fins, or 3D-printed scaffolds.

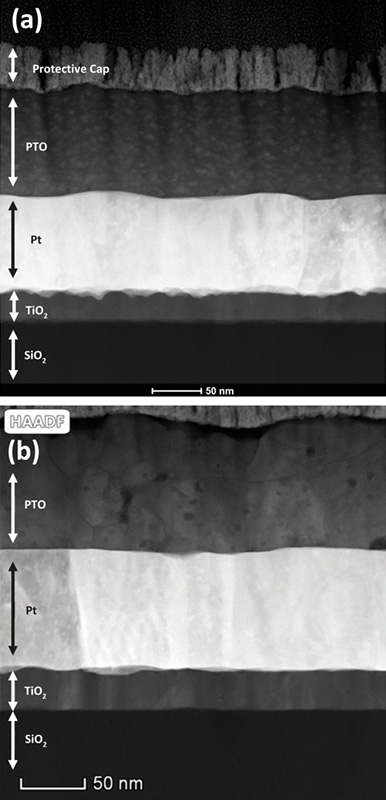

Given the technological functionality of PZT, it is a wonder it has not received more attention from the ALD community. Dr. Strnad remarks, "Historically, the problems with past attempts to grow lead-containing perovskites by ALD have been significant lead-deficiency and high leakage current density. These new films seem to crystallize in a radically different way, forming nanometer-scale non-columnar domains which we think reduces the leakage current."

An example of the unique crystal structure for lead titanate (PbTiO3, or PTO) is shown in Fig. 1 (reprinted with permission from Ref. 1)

Dr Strnad's dissertation (ref. 2) contains details related to several other perovskite ALD processes, including: antiferroelectric lead hafnate (PbHfO3, or PHO), ferroelectric lead hafnate titanate (PbHfxTi1-xO3, or PHT), PZT, and PTO. The dissertation is available for free download at the DRUM https://doi.org/10.13016/8dqx-7pev.

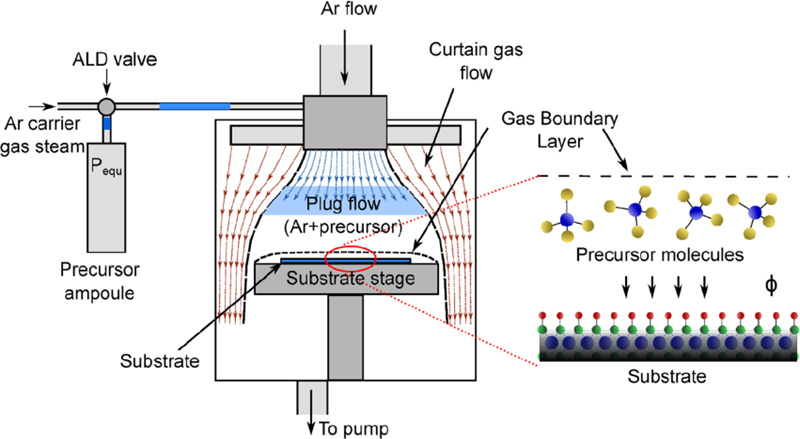

The new films were grown using a Kurt J. Lesker Company model ALD-150LX atomic layer deposition (ALD) system equipped with a load lock, 6" wafer handling capability and in-situ ellipsometry capabilities. The ALD-150LX has substrate heating capability to 500°C as well as remote plasma capability. The system utilizes the patented Lesker Precursor Focusing Technology™ (Ref. 6) with Ar, H2O and O3 delivery systems.

References:

- Strnad, NA et al. J. Vac. Sci. Technol. A 37(2) Mar/Apr 2019; doi: 10.1116/1.5080226

- Strnad, NA (2019) Atomic Layer Deposition of Lead Zirconate-Titanate and Other Lead-Based Perovskites (Doctoral Dissertation); https://doi.org/10.13016/8dqx-7pev

- Aggarwal S, Udayakumar KR, Rodriguez JA. Stoichiometry and phase purity of Pb(Zr, Ti)O3 thin films deposited by metal organic chemical vapor deposition J Appl Phys. 2006;100:064103.

- http://www.xaar.com/en/products/xaar-printheads/

- Pulskamp JS, Polcawich RG. Three Dimensional Piezoelectric MEMS, US8966993 B2. 2012

- G. Bruce Rayner, Jr. Atomic Layer Deposition Apparatus And Process, US 9,695,510 B2. 2017