Quality

Quality Standards and Certifications

ISO 9001:2015

KJLC Manufacturing gained ISO 9001:2015 standard certification in 2004. However, we are well aware that quality is not about a certificate, it is about process and dedication.

ASME Section IX Welding Standard

KJLC Manufacturing welders are qualified to AWS D1.6, assuring our commitment for delivering high quality weld processes.

Inspection

In-process inspections are made at every step by the KJLC Manufacturing team member responsible for that step. At select stages and again on job completion the product is inspected by our experienced quality control technicians using the appropriate manual inspection tools or a coordinate measuring machine. Complex parts are dimensionally checked with a FARO coordinate measuring machine.

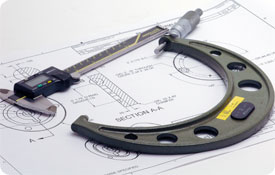

KJLC has a full complement of calibrated inspection equipment including calipers, bore gauges, pin gauges, micrometers, thread gauges, optical comparators and profilometers. Every inspection tool used by KJLC Manufacturing carries an identification tag and is re-calibrated on its scheduled date. Calibration is done by in-house QC team (using transfer standards) and outside team as required.

KJLC Manufacturing tests all vacuum components and assemblies with state of the art helium leak detectors (ultimate sensitivity of 10-12 atm cc/sec He). Leak check certifications are provided for any product upon request and can be performed to ASTM E 498 or 499 standards as required.

Metrology

Geometric dimensioning and tolerances to the ASME Y14.5-2009 standard

Dye Penetrant Testing

KJLC Manufacturing has the ability to perform Dye / Liquid penetrant testing to ASTM E-1417. This inspection method is used to locate surface-breaking defects in all non-porous materials.

In-Process Inspection

KJLC Manufacturing has a full complement of inspection equipment including; calipers, bore gauges, pin gauges, micrometers, thread gauges, optical comparators, profilometers and CMM.

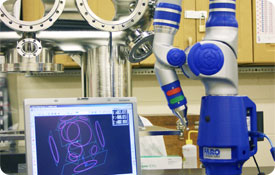

Coordinate Measuring Machine

KJLC Manufacturing dimensionally checks complex parts with a FARO coordinate measuring machine

Calibration

Every inspection tool used by KJLC Manufacturing carries an ID sticker and is logged into a tracking program to ensure re-calibration on its scheduled date. Calibration is done by in-house QC team (using transfer standards) and outside services as required.

Helium Leak Detection

KJLC Manufacturing tests all vacuum components and assemblies with state-of-the-art helium leak detectors. Our helium leak detectors have an ultimate sensitivity of 10-12 atm cc/sec. Leak check certifications are provided for any product upon request and leak detection can be performed to ASTM E 498 or 499 as required.