Cerium Oxide (CeO2) Pieces Evaporation Materials

Cerium Oxide (CeO2) Pieces Overview

We sell these pellets and pieces by unit weight for evaporation use in deposition processes. These approximate materials prices are published to provide budgetary guidelines. Actual prices can vary and may be higher or lower, as determined by availability and market fluctuations. To speak to someone directly about current pricing, please click here .

Cerium Oxide (CeO2) General Information

Cerium oxide, also known as ceria, is an inorganic chemical compound with a chemical formula of CeO2. It is white or pale yellow in color with a density of 7.13 g/cc, a melting point of ~2,600°C, and a vapor pressure of 10-4 Torr at 2,310°C. It is primarily used for polishing but can also be found as a sensor in catalytic converters in automobiles. Cerium oxide is evaporated under vacuum to form anti-reflective layers for optical coatings and as buffer layers in high temperature superconductors.

Cerium Oxide (CeO2) Specifications

| Material Type | Cerium (IV) Oxide |

| Symbol | CeO2 |

| Color/Appearance | White or Pale Yellow, Crystalline Solid |

| Melting Point (°C) | ~2,600 |

| Theoretical Density (g/cc) | 7.13 |

| Z Ratio | **1.00 |

| E-Beam | Good |

| Thermal Evaporation Techniques |

Boat: W |

| E-Beam Crucible Liner Material | Tantalum, Graphite, FABMATE® |

| Temp. (°C) for Given Vap. Press. (Torr) |

10-8: 1,890 10-6: 2,000 10-4: 2,310 |

| Comments | Very little decomposition. |

| Suggested QCM Crystal | Alloy Crystal: 750-1002-G10**** |

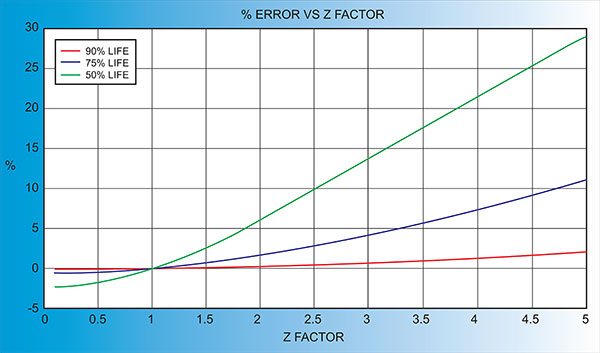

** The z-ratio is unknown. Therefore, we recommend using 1.00 or an experimentally determined value. Please click here for instructions on how to determine this value.

**** Suggestion based on previous experience but could vary by process. Contact local KJLC Sales Manager for further information

Empirical Determination of Z-Factor

Unfortunately, Z Factor and Shear Modulus are not readily available for many materials. In this case, the Z-Factor can also be determined empirically using the following method:

- Deposit material until Crystal Life is near 50%, or near the end of life, whichever is sooner.

- Place a new substrate adjacent to the used quartz sensor.

- Set QCM Density to the calibrated value; Tooling to 100%

- Zero thickness

- Deposit approximately 1000 to 5000 A of material on the substrate.

- Use a profilometer or interferometer to measure the actual substrate film thickness.

- Adjust the Z Factor of the instrument until the correct thickness reading is shown.

Another alternative is to change crystals frequently and ignore the error. The graph below shows the % Error in Rate/Thickness from using the wrong Z Factor. For a crystal with 90% life, the error is negligible for even large errors in the programmed versus actual Z Factor.

Thermal Evaporation of Cerium Oxide (CeO2)

Because cerium oxide's vapor pressure is below its melting point (~2,600°C), it will sublime from a solid phase. We recommend using a thick gauge, high current tungsten boat such as our EVS20A015W. With an evaporation temperature of ~2,600°C, we estimate a deposition rate of 2-5 angstroms per second. A partial pressure of O2 at 5 x 10-5 Torr is recommended.

E-beam Evaporation of Cerium Oxide (CeO2)

Cerium oxide can be e-beam evaporated from a FABMATE®, tantalum, or graphite crucible liner.

If possible, Ion Assisted Deposition (IAD) is preferred when e-beam evaporating cerium oxide. We recommend to sweep the beam to fully melt the material and avoid hole drilling. We estimate a deposition rate of 2-5 angstroms per second when the evaporation temperature is at ~2,600°C. A partial pressure of O2 at 5 X 10-5 Torr is recommended. Under these parameters, we expect low-stress films which are columnar, soft and porous, with good adhesion. Thick films will have a rough surface.

A key process note is to consider the fill volume of the crucible liner. We find that the melt level of a material in the crucible directly affects the success of the crucible liner. Overfilling the crucible will cause the material to spill over and create an electrical short between the liner and the hearth. The outcome is cracking in the crucible liner. This is the most common cause of crucible liner failure. Placing too little material in the liner or evaporating too much material before refilling can be detrimental to the process as well. When the melt level is below 30%, the e-beam is likely to strike the bottom or walls of the crucible which immediately results in breakage. Our recommendation is to fill the crucible between 2/3 and 3/4 full to prevent these difficulties.

Crucible liners should be stored in a cool, dry place and always handled with gloves or forceps.

See highlighted results that match your result in the table below.

Ordering Table

| More Info | Material | Description | Size | Quantity | Purity | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|---|---|---|

| More Info | Material | Description | Size | Quantity | Purity | Part Number | Price | In Stock | Add To Cart |

| Cerium Oxide |

CERIUM OXIDE PIECES, |

1mm - 4mm | 50g | 99.99% | EVMCEO1-4B | P.O.R. |

|

||

| Cerium Oxide |

CERIUM OXIDE PIECES, |

1mm - 4mm | 100g | 99.99% | EVMCEO1-4D | P.O.R. |

|

||

| Cerium Oxide |

CERIUM OXIDE PIECES, |

1mm - 4mm | 1kg | 99.99% | EVMCEO1-4KG | P.O.R. |

|

||

| Cerium Oxide |

CERIUM OXIDE PIECES, |

1mm - 4mm | 25g | 99.99% | EVMCEO1-4MMA | P.O.R. |

|

||

| Cerium Oxide |

CERIUM OXIDE PIECES, |

1mm - 4mm | 500g | 99.99% | EVMCEO1-4T | P.O.R. |

|