Industry Leading Water Cooling

Water cooling is required when equipment is being heated beyond the temperature limits of the seals and material of construction and to ensure a safe environment for those working with the equipment.

We have extensive experience of managing projects where temperature control has been critical to the success of a project.

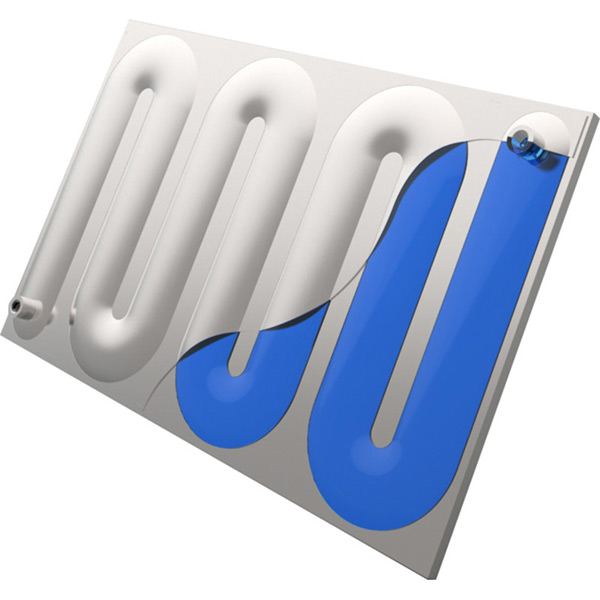

This new method of water cooling is made by welding a trace to a chamber and then using water pressure to hydro-form the water channel.

Radiused bends improve water flow and help eliminate low flow and stagnant areas.

- Highly configurable

- Superior surface area coverage

- Improved corrosion resistance

- Improved flow

- Reduced volume of cooling water

- Minimal protrusion to the atmosphere side

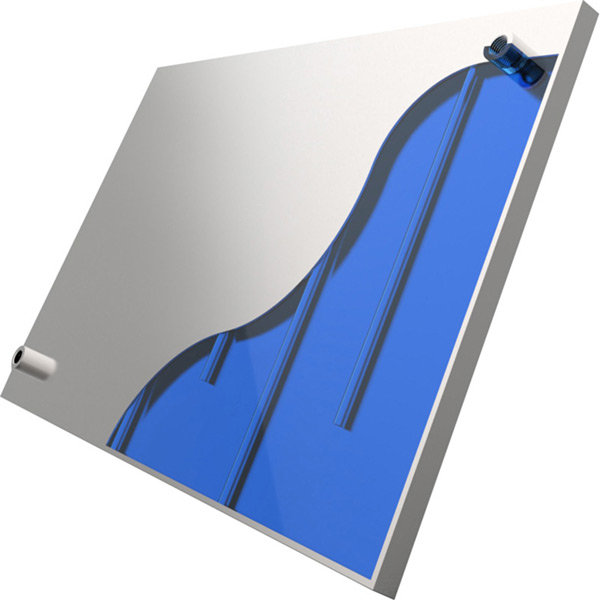

Double Wall

Double chamber walls with channelling and baffles provide a cold wall.

- For applications with high heat outputs

- Complicated for chambers with many ports

- Can be susceptible to low flow area and crevice corrosion

- Expensive

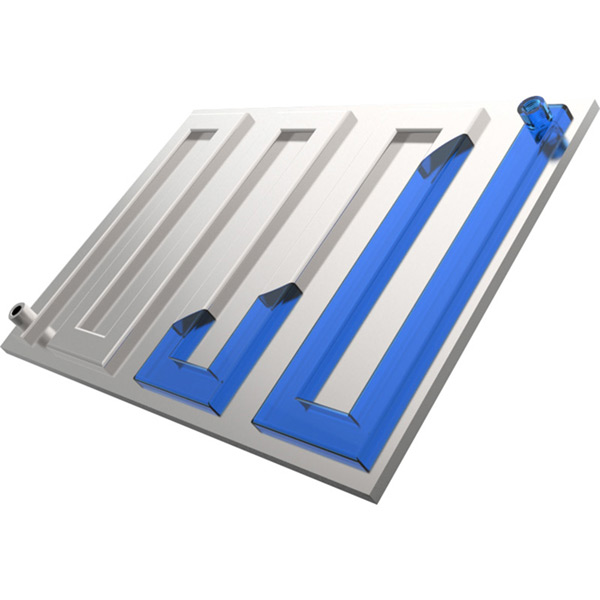

Welded Water Trace

Formed by welding a channel to the external chamber surface.

- For lower heat outputs

- Low surface area coverage

- Lower cost than double wall cooling

- Can be susceptible to low flow area and crevice corrosion