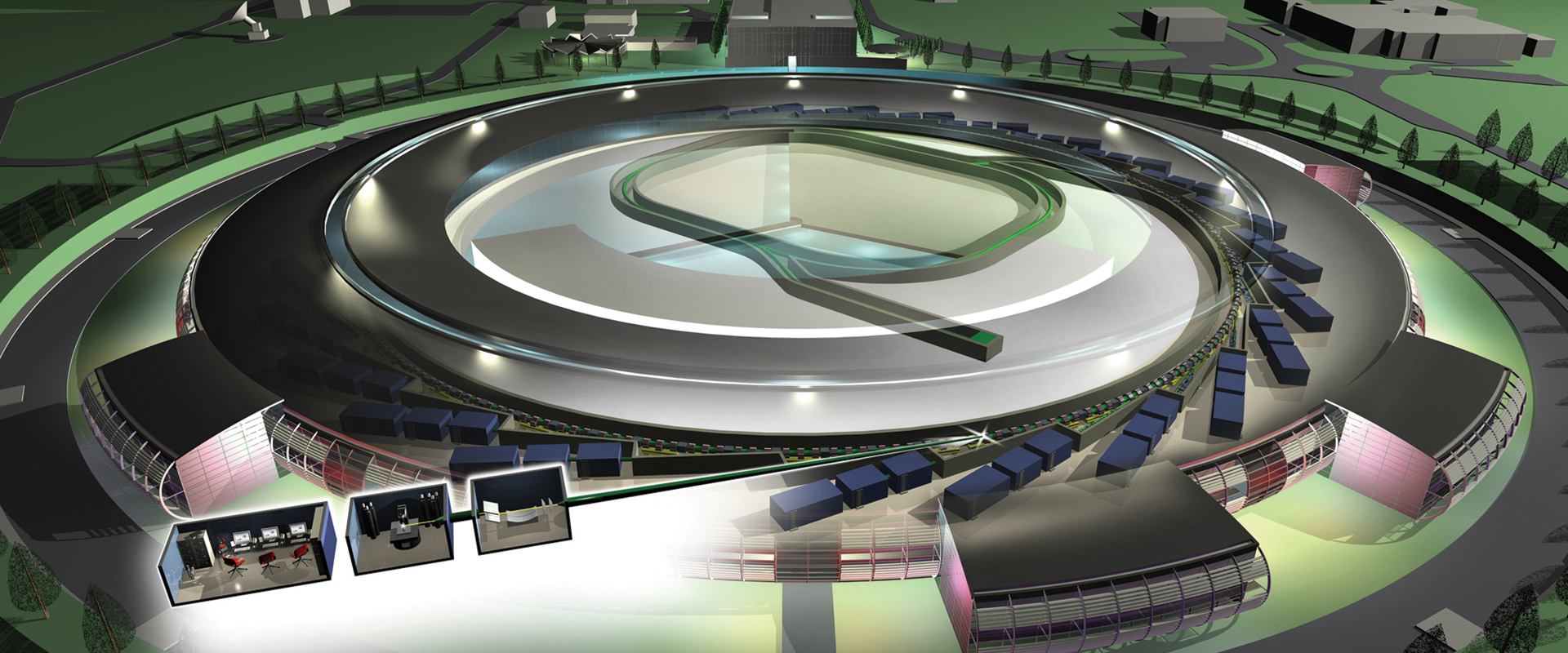

Synchrotron *Image courtesy of the Diamond Light Source.

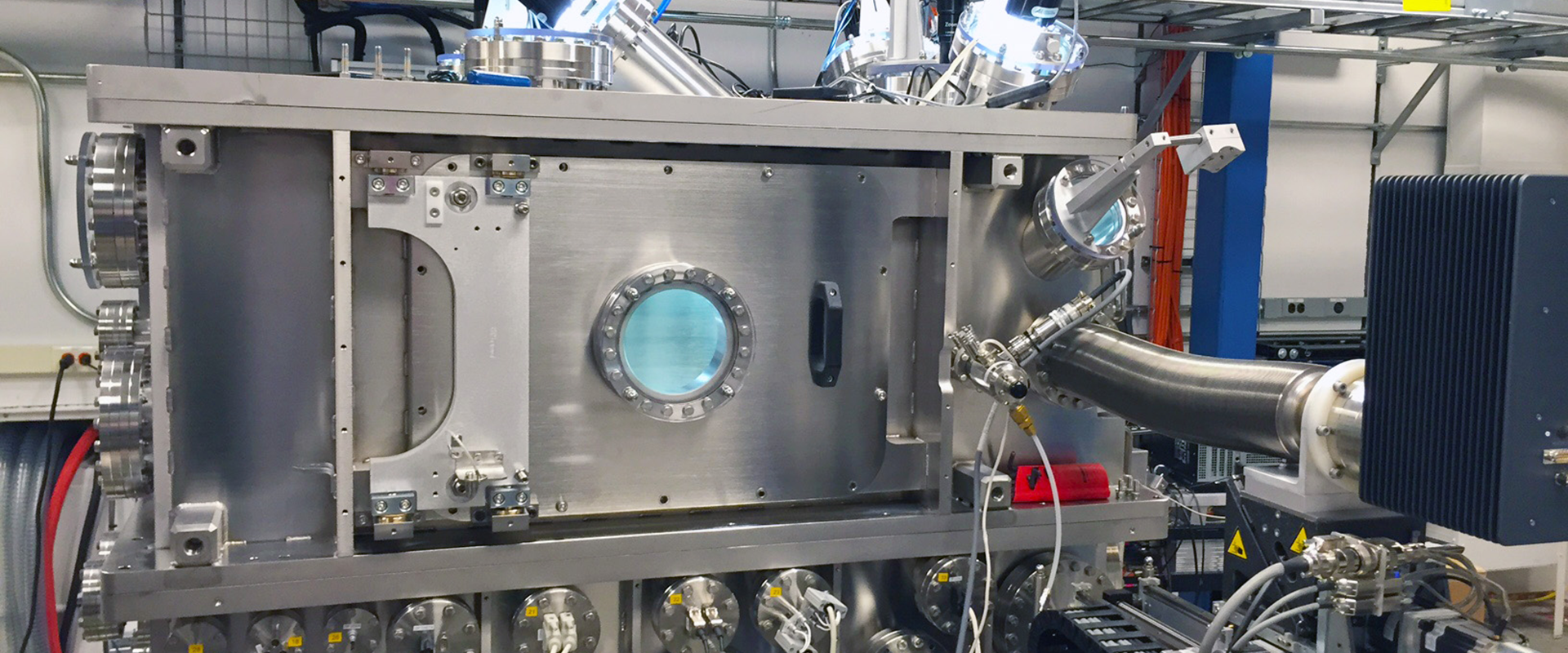

HXN End Station at the BNL NSLSII

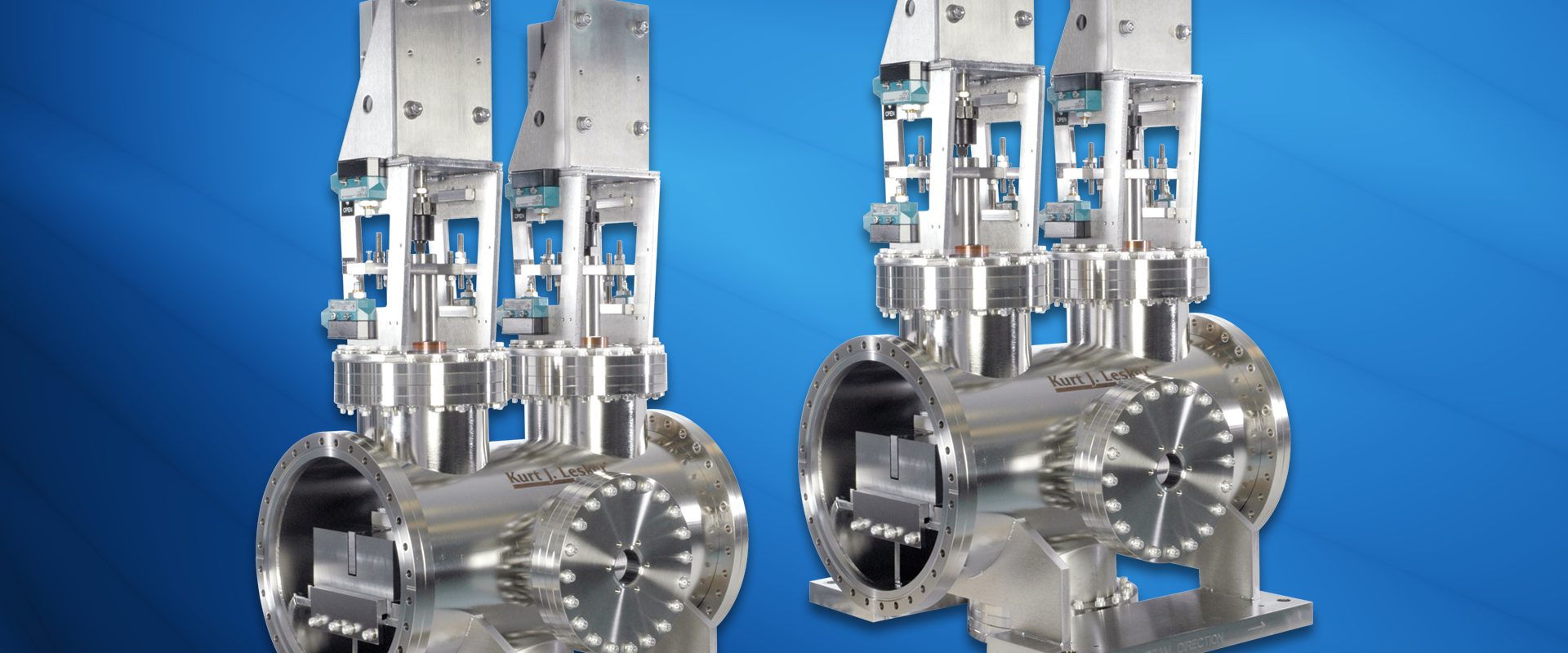

Safety Shutters

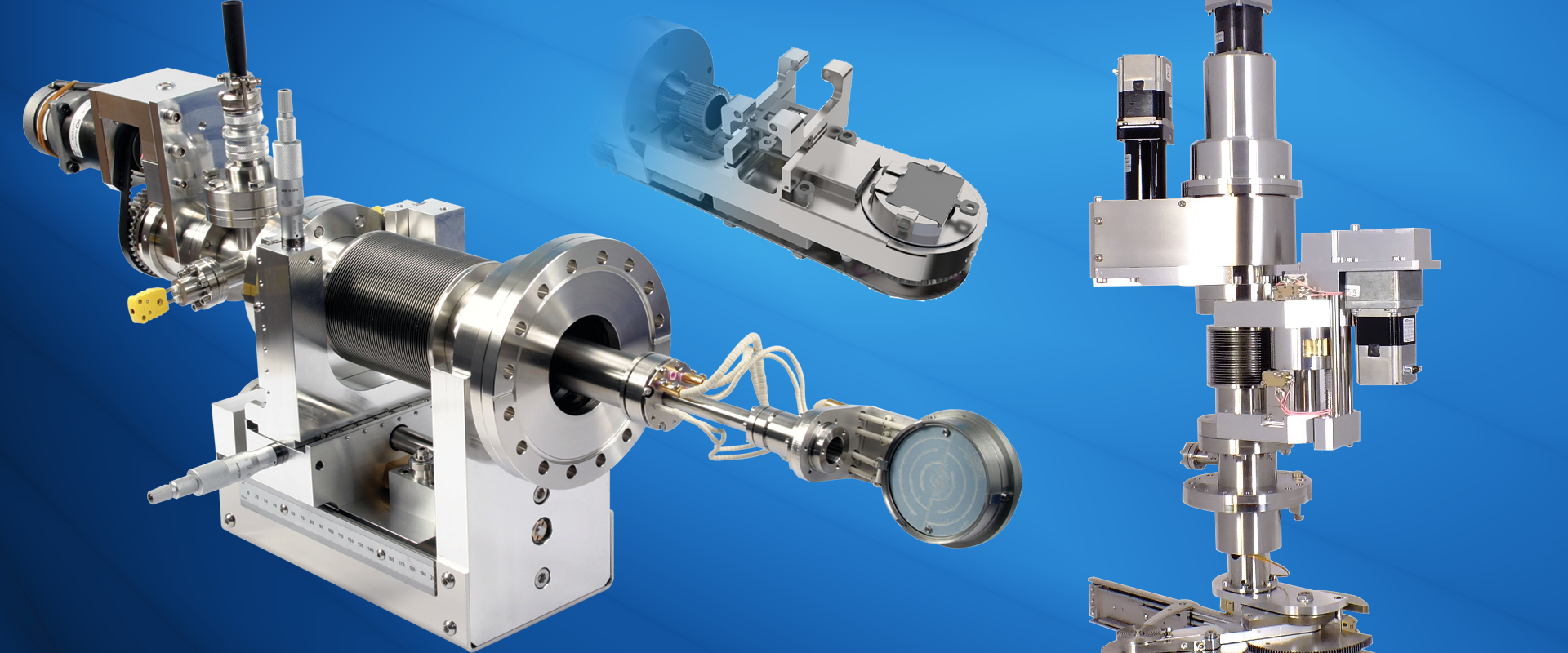

Beam Line Manipulation and Motion

End Station Manipulation

Front End Components – Shutters, Masks, Absorbers, Collimators, etc.

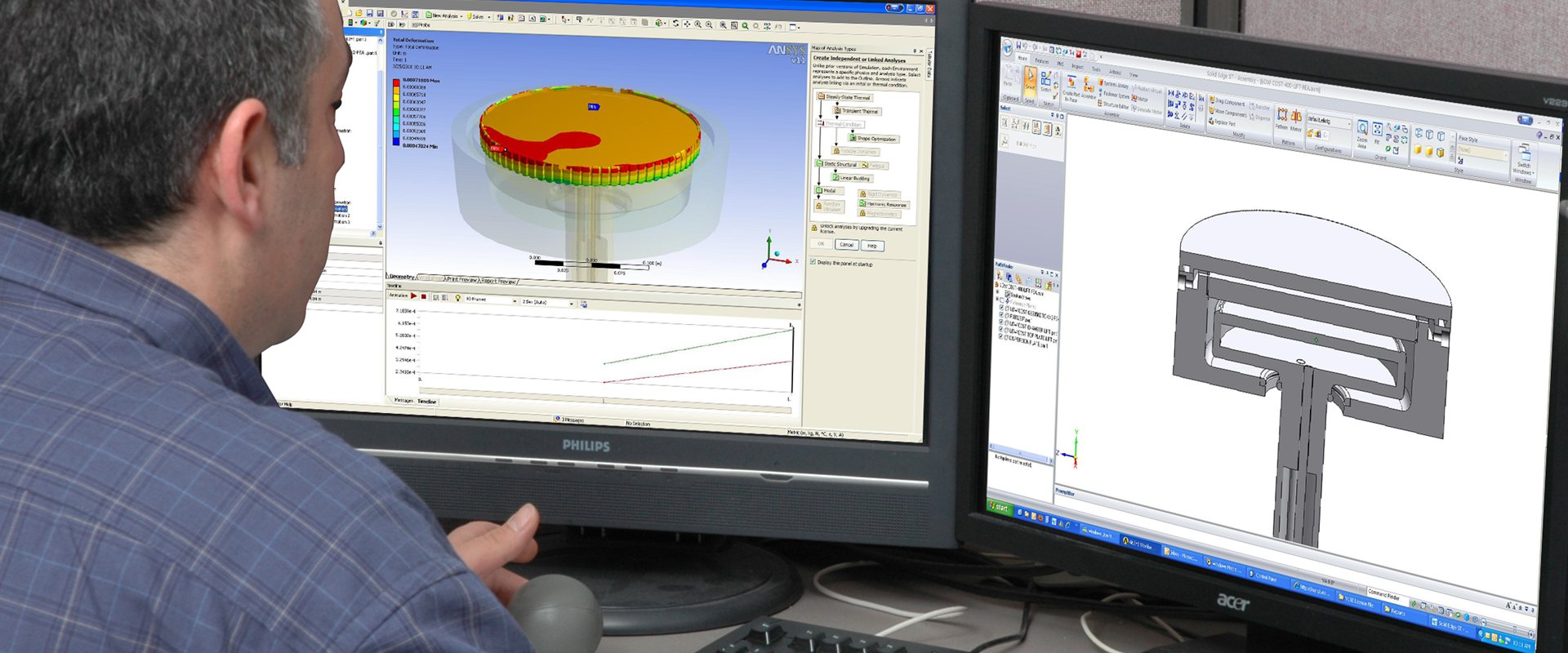

Finite Element Analysis

UHV/Synchrotron Overview

KJLC® offers an extensive list of beam line components and build to print UHV services. The Kurt J. Lesker Company offers a full catalog of standard and custom products to service the UHV/Synchrotron market, including CF flange systems, chambers, feedthroughs and advanced UHV manipulators.

For more than 25 years, KJLC has been a manufacturer of UHV vacuum hardware, weldments, subassemblies and turnkey deposition systems.

UHV/Synchrotron Capabilities

- KJLC's ISO 9000 certified fully equipped machining and fabrication facility

- 30 design and manufacturing engineers

- Positive air flow clean assembly areas

- Large capacity CNC turning and milling

- ASME Section IX Certified Welders

- 5 Axis Coordinate Measuring Machine (CMM)

- Helium leak detection ultimate sensitivity of 1.0E-12 atm cc/sec.

- 5 axis laser

- Deionized water rinse

- Nitrogen gas high pressure drying

- UHV dedicated vacuum bake

- UHV dedicated tooling

- Dedicated global product specialists to help you find the right product for your application

UHV/Synchrotron Offerings

KJLC offers a number of products to the UHV Synchrotron market including standard catalog items, building to customer supplied prints, and a multitude of component designs.

Synchrotron Offerings

The Kurt J. Lesker Company can help engineer and manufacture many aspects of a Beam Line:

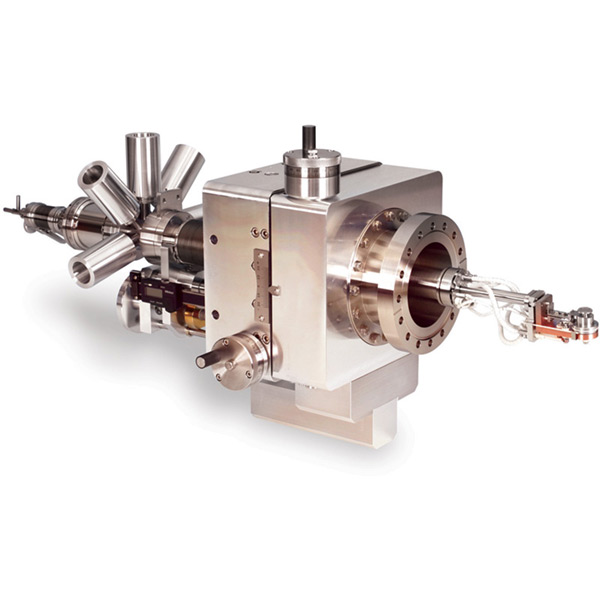

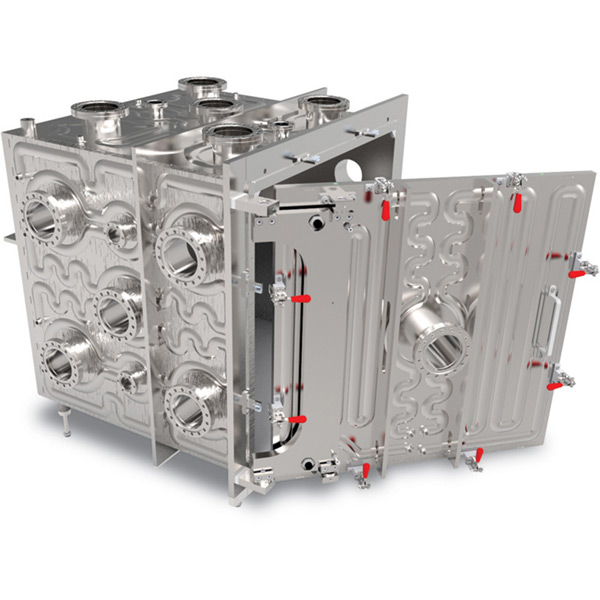

Vacuum Chambers and End Stations

End stations are where the hundreds of millions of dollars worth of sophisticated equipment that make up synchrotrons finally get put to work. KJLC can design and manufacture end stations that require.

- Finite element analysis to assure high stability, and minimal deflection under vacuum

- Stringent vibrational mode criteria

- Pump down modeling

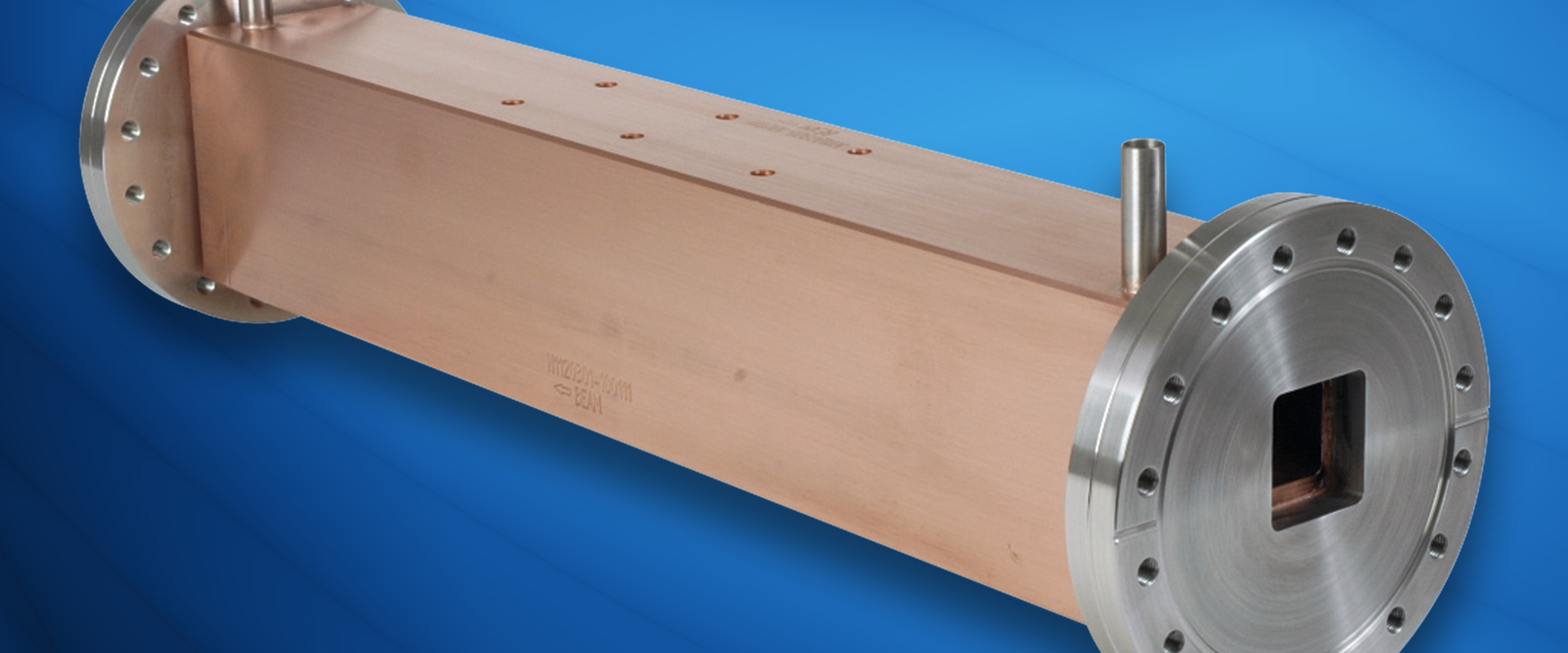

Beam Filters & Slit Assemblies

- Beam Filters are intended to attenuate the beam and controller the passage of selective wavelengths.

- Beam Slits are designed to trim the size and shape of the beam. They can be water cooled to absorb the heat load from a white bream or non-cooled for monochromatic beams.

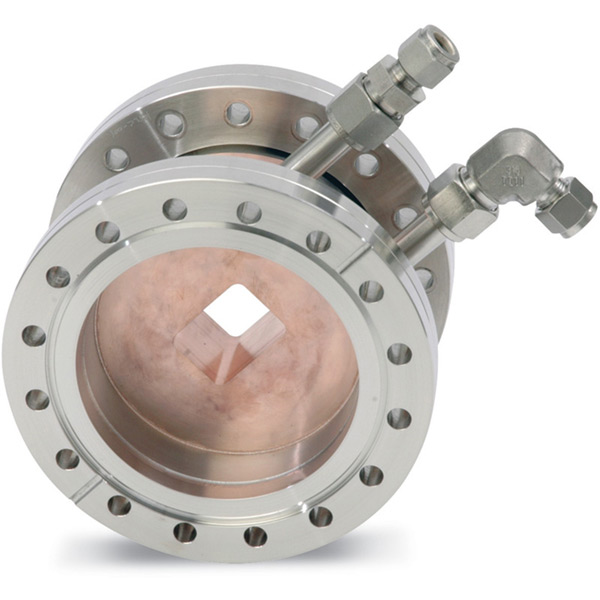

Safety Shutters

Safety Shutters are devices designed to block the passage of radiation in case of catastrophic failure. For blocking X-rays in UHV environments the material of choice is typically high purity tungsten.

Front End Components – Shutters, Masks, Absorbers, Collimators, etc.

Standardizing front end components across similar beam lines can be an effective way to reduce cost and lead time. KJLC can build to print or modify in-house designs to suit customer needs.

Manipulation & Motion Offerings

By combining true UHV design principles with experience in demanding industry applications, our manipulation and motion products ideally suit the rigorous requirements of synchrotrons for precision, long-life and vacuum performance:

Linear Shifts

A Linear Shift is a pair of flanges connected by a bellows. One flange is free to move along its axis in relation to the other. The motion is constrained by a rugged, precise slide mechanism so the flange faces are always parallel. Linear shifts have a through bore to enable wide diameter devices to be inserted into the vacuum chamber and moved linearly between limits. Linear shifts are actuated by hand-wheels or, for higher precision, stepper motors.

More Info ▶Linear Positioners - Magnetically Coupled

Linear Positioners are bellows-sealed or magnetically coupled rods that move along the rod's axis. The mechanisms are either manually or pneumatically actuated, enabling a push-pull motion between two stop positions. Another method is a precise screw mechanism, with manual or motorized actuation, that can be stopped at any intermediate position between its travel limits.

Positioners are used in applications needing straightline, fixed distance movement; for example, beamstops, shutter actuators, substrate movements, etc., at all pressures between atmosphere and UHV.

Linear positioners sealed with elastomeric o-rings or "knife-edge" seals are available and perform the same functions. However, like other "dynamic seal" devices, they are compatible with pressures between atmosphere and ~10-5 Torr.

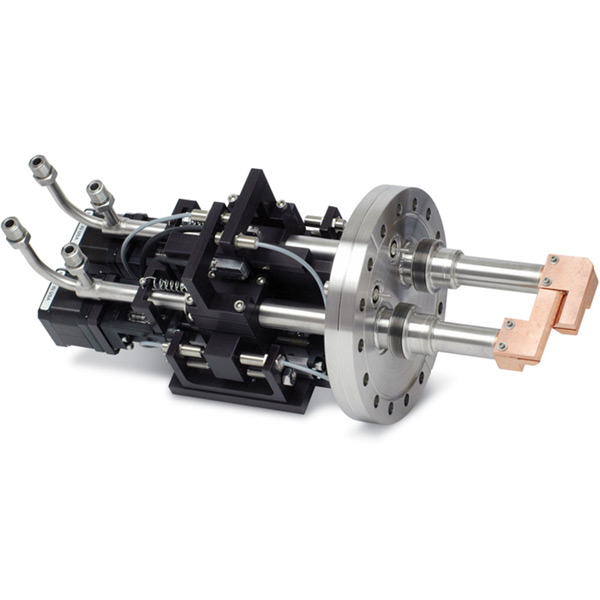

More Info ▶Multi-Axis Manipulation

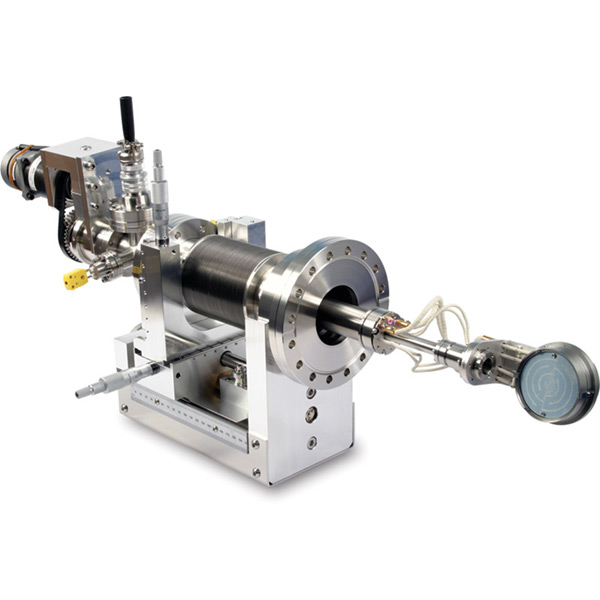

For applications requiring multiple axes of translation, tilt, rotation, or perhaps, sample heating/cooling and transfer, this product range can compound their various modular components to build sophisticated manipulators with up to six axes of independent motion.

More Info ▶MultiCentre Sample Handling Systems (M.S.H.S.)

The MultiCentre provides a complete solution for sample transfer and manipulation. Typical applications include analytical instrumentation for surface analysis equipment and synchrotron end stations.

More Info ▶Sample Transfer Devices

PowerProbe sample transfer arms enable secure transfer of samples within UHV. In addition to linear and linear/rotary probes, this extensive range includes the Elevating PowerProbe and the Dual-Axis Probe designed to transfer specific "industry standard" sample holders using a variety of actuation methods.

More Info ▶Custom Surface Analysis Sample Stages

MultiCentre stages provide high stability multi-axis sample manipulation for synchrotron end stations and surface analysis systems.

More Info ▶Radial Telescopic Transfer Arm (RTTA)

The Radial Telescopic Transfer Arm (RTTA) design provides the ability to rotate an "Arm" assembly to radial face ports about the chamber circumference. The RTTA provides a sample position stroke of ~760mm. Fully withdrawn it will fit in a chamber with an internal diameter of 630mm, whilst holding a sample up to 138mm in diameter. The outcome of this design is that the customers' chamber can be much smaller than other designs, saving cost on the chamber, pumps and frame as well as reducing the overall footprint of the system.

More Info ▶UHV Components Offerings

We manufacture and supply the widest selection of internationally compatible UHV components for the Synchrotron industry:

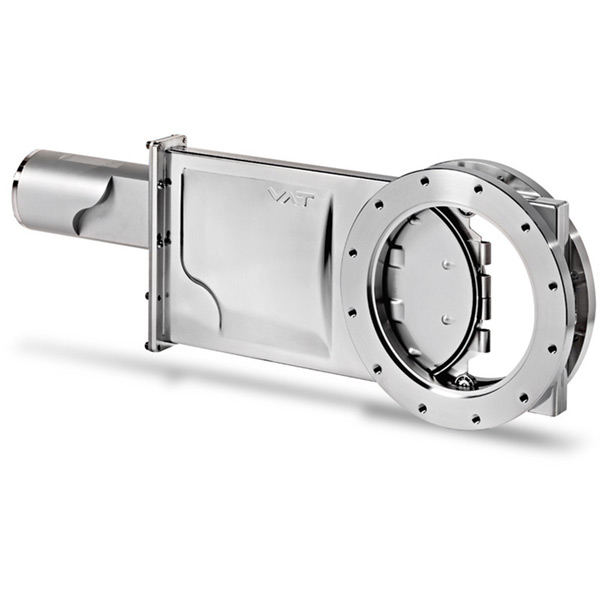

Gate Valves

Gate valve applications include isolation between vacuum volume and pump, isolation between chamber and loadlock during sample introduction to the latter, access between chamber and loadlock during sample transfer, and isolation between synchrotron beam lines and experimental stations.

More Info ▶All-Metal Valves

These valves are suitable for a variety of UHV and extreme UHV applications. For example as shut-off device in the front ends and beamlines of synchrotrons and pumping systems, as sector valve in booster synchrotrons and LINACS, as transfer valve in MBE and coating systems, as isolation valve on systems with increased temperatures etc.

More Info ▶VAT Valves

VAT has built its reputation with uncompromising quality. As the leading manufacturer and distributor of high-quality vacuum products and systems, KJLC can now provide you with the most trusted name in valves across the globe for your application.

More Info ▶CF Flanges & Components

Sealing non-permanent joints (any thing that's not welded) in UHV applications is most typically done with metal gaskets sandwiched between CF flanges.

KJLC offers a wide variety of CF flanges, CF flanged components, CF hardware, and CF gaskets.

More Info ▶Plated Hardware

We manufacture a full range of OFHC Copper, annealed copper, aluminum and gold and silver plated, and elastomeric fluorocarbon gaskets for CF flanges. Metal gaskets are impermeable to gases and withstand moderately high temperatures indefinitely. The CF flange is the most widely used for high vacuum and UHV applications.

More Info ▶Magnetically Levitated Pumps

For truly dry chambers, a turbo pump with magnetically levitated bearings backed by a dry mechanical pump are used. With proper venting, the turbo mechanism stops in less than a minute, which may mean chamber venting is accomplished without the need for a valve separating pump and chamber.

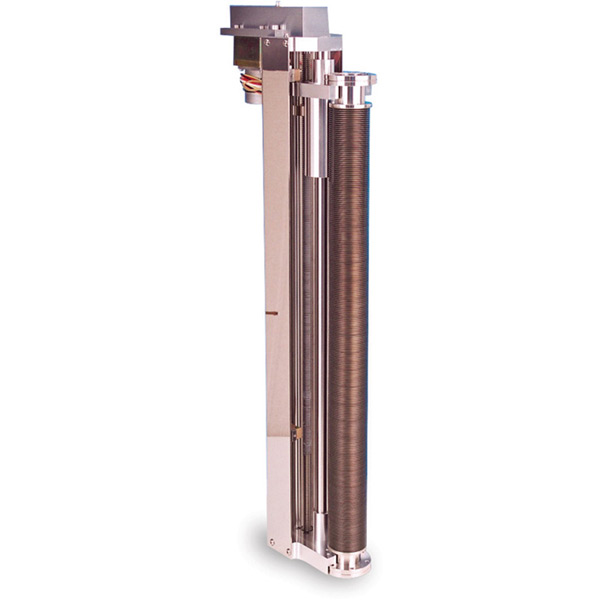

More Info ▶Ion Pumps

Ion pumps are the primary choice for all true UHV chambers. They are clean, bakeable, vibration-free, operate from 10-6 Torr to 10-11 Torr with low power consumption, and have long operating lives.

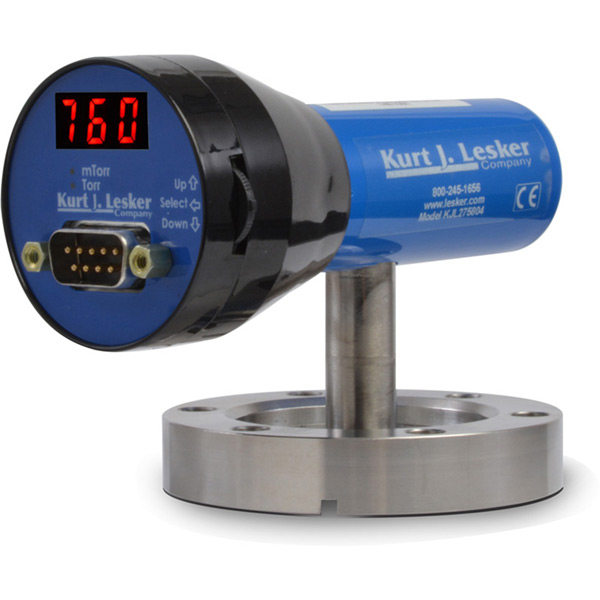

More Info ▶Vacuum Gauging

The Kurt J. Lesker Company has gauging solutions for UHV applications. EB degas nude UHV B-A ionization gauges are available as well as controllers to operate them. KJLC also provides other various types of gauges, including thermocouple, convection enhanced pirani, and hot cathode ion gauges. This gives the customer the ability to measure pressure during all steps of the application, from initial pump down to UHV.

More Info ▶Manufacturing & Engineering Services

KJLC's team of manufacturing and engineering professionals are skilled at precision handwelding, addressing tough technical problems and finding the right answers.

Custom Manufacturing

Vacuum chambers are built in a wide variety of shapes and sizes, limited only by application, imagination, and engineering consideration.

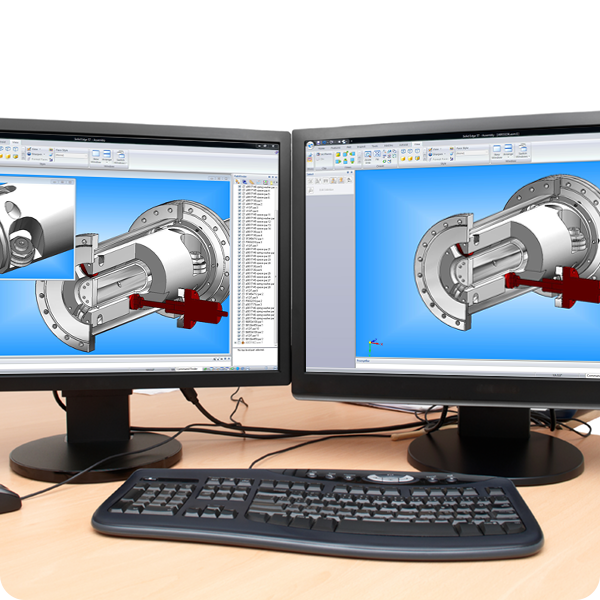

More Info ▶Mechanical Engineering

KJLC's engineering department is staffed with mechanical engineers, mechanical designers, and professional engineers who are thoroughly versed in all aspects of product design, manufacturing, assembly, and testing. In addition to full scale design projects, engineers are assigned to aid in design-for-manufacture and cost reduction efforts.

Manufacturing Engineering

KJLC Manufacturing engineers work closely with our mechanical engineers, material procurement personnel, and shop supervisors to identify steps that will improve quality, reduce manufacturing time, and reduce project costs.

Industrial Engineering

At KJLC Manufacturing, Lean is a way of life: continuous improvement; 5S; cellular manufacturing; kanban material replenishment; and visual work instructions are some of the ways our shop team and industrial engineers work together to make all products better, faster, and with fewer errors.

Project Management

All KJLC Manufacturing projects are assigned a project manager to ensure proper handling from start to finish. With the aid of a production router, the project manager controls the manufacturing process and time-line, actively identifying problem areas and coordinating efforts to develop solutions.

Production Scheduling

KJLC Manufacturing uses a powerful scheduling program with real-time data collection to help ensure on-time delivery and forecast/plan capacities across the manufacturing floor. The program provides load charts, machine schedules, and rolling lead times to assist in quoting realistic deliveries and helping supervisors to better determine real capacity.

Manufacturing Materials

KJLC has experience with many materials used in Synchrotron components such as: Stainless Steel (including 316LN), Aluminum, Copper, GlidCop®, Invar, Inconel®, Tungsten, Titanium, Molybdenum, etc.

Vacuum Bakeout & Firing

A high temperature (above 200°C) bakeout under vacuum is required for many UHV and Synchrotron components.

- Effective in removing water vapor, cleaning solutions, hydrocarbons and other contaminants from the system

-

RGA acceptance scans are often required to prove this

- Each peak represents the partial pressure of an Atomic Mass Unit (AMU)

- From the peaks it can be determined what molecules are in the chamber, proving cleanliness

Vacuum Firing

- Vacuum Firing to over 950°C helps to drive off Hydrogen absorbed into the stainless steel wall of vacuum chambers. This same process can also be used to lower the magnetic permeability of 300 series stainless steels.

KJLC has experience in both of these processes for clean, UHV compatible vacuum chambers.