Titanium Dioxide (TiO2) Sputtering Targets Overview

Our comprehensive offering of sputtering targets, evaporation sources and other deposition materials is listed by material throughout the website. Below you will find budgetary pricing for sputtering targets and deposition materials per your requirements. Actual prices may vary due to market fluctuations. To speak to someone directly about current pricing or for a quote on sputtering targets and other deposition products not listed, please click here.

Titanium Dioxide (TiO2) General Information

Titanium dioxide is a chemical compound with a chemical formula of TiO2. It is white in appearance with a density of 4.26 g/cc, a melting point of 1,830°C, and a vapor pressure of 10-4 Torr at ~1,300°C. The largest commercial application of titanium dioxide is as a white pigment for paint due to its brightness and high refractive index. It is also a principal ingredient in sunscreen because of its unique ability to absorb UV light. It is evaporated under vacuum primarily for reflective optical coatings and optical filters.

Titanium Dioxide (TiO2) Specifications

| Material Type | Titanium (IV) Oxide |

| Symbol | TiO2 |

| Color/Appearance | White-Beige, Gray-Black |

| Melting Point (°C) | 1,830 |

| Theoretical Density (g/cc) | 4.23 |

| Z Ratio | 0.4 |

| Sputter | RF, RF-R |

| Max Power Density (Watts/Square Inch) | 20* |

| Type of Bond | Indium, Elastomer |

| Comments | Suboxide, must be reoxidized to rutile. Ta reduces TiO2 to TiO and Ti. |

* This is a recommendation based on our experience running these materials in KJLC guns. The ratings are based on unbonded targets and are material specific. Bonded targets should be run at lower powers to prevent bonding failures. Bonded targets should be run at 20 Watts/Square Inch or lower, depending on the material.

* Suggested maximum power densities are based on using a sputter up orientation with optimal thermal transfer from target to the sputter cathode cooling well. Using other sputtering orientations or if there is a poor thermal interface between target to sputter cathode cooling well may require a reduction in suggested maximum power density and/or application of a thermal transfer paste. Please contact techinfo@lesker.com for specific power recommendations.

Empirical Determination of Z-Factor

Unfortunately, Z Factor and Shear Modulus are not readily available for many materials. In this case, the Z-Factor can also be determined empirically using the following method:

- Deposit material until Crystal Life is near 50%, or near the end of life, whichever is sooner.

- Place a new substrate adjacent to the used quartz sensor.

- Set QCM Density to the calibrated value; Tooling to 100%

- Zero thickness

- Deposit approximately 1000 to 5000 A of material on the substrate.

- Use a profilometer or interferometer to measure the actual substrate film thickness.

- Adjust the Z Factor of the instrument until the correct thickness reading is shown.

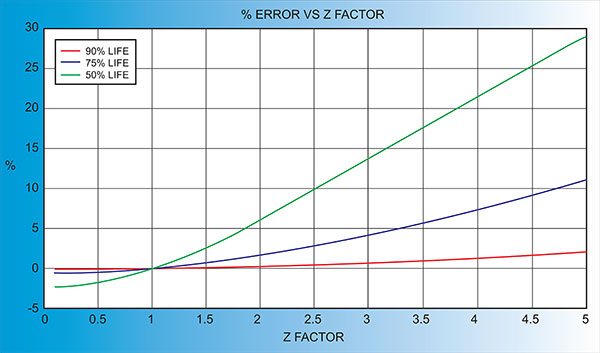

Another alternative is to change crystals frequently and ignore the error. The graph below shows the % Error in Rate/Thickness from using the wrong Z Factor. For a crystal with 90% life, the error is negligible for even large errors in the programmed versus actual Z Factor.

Ordering Table

| More Info | Material | Description | Size | Purity | Color | Compatible Guns | Notes | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|---|---|---|---|---|

| More Info | Material | Description | Size | Purity | Color | Compatible Guns | Notes | Part Number | Price | In Stock | Add To Cart |

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

1.00" Dia. x 0.125" Thick | 99.9% | Grey to Black | Most Standard Guns | 1 | EJTTIO2301A2 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

1.00" Dia. x 0.125" Thick | 99.99% | Beige to White | Most Standard Guns | 1 | EJTTIO2401A2 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

1.00" Dia. x 0.250" Thick | 99.9% | Grey to Black | Most Standard Guns | 1 | EJTTIO2301A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

1.00" Dia. x 0.250" Thick | 99.99% | Beige to White | Most Standard Guns | 1 | EJTTIO2401A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

2.00" Dia. x 0.125" Thick | 99.9% | Grey to Black | Most Standard Guns | 1 | EJTTIO2302A2 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

2.00" Dia. x 0.125" Thick | 99.99% | Beige to White | Most Standard Guns | 1 | EJTTIO2402A2 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

2.00" Dia. x 0.250" Thick | 99.9% | Grey to Black | Most Standard Guns | 1 | EJTTIO2302A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

2.00" Dia. x 0.250" Thick | 99.99% | Beige to White | Most Standard Guns | 1 | EJTTIO2402A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

3.00" Dia. x 0.125" Thick | 99.9% | Grey to Black | Most Standard Guns | 1 | EJTTIO2303A2 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

3.00" Dia. x 0.125" Thick | 99.99% | Beige to White | Most Standard Guns | 1 | EJTTIO2403A2 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

3.00" Dia. x 0.250" Thick | 99.9% | Grey to Black | Most Standard Guns | 1 | EJTTIO2303A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

3.00" Dia. x 0.250" Thick | 99.99% | Beige to White | Most Standard Guns | 1 | EJTTIO2403A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

4.00" Dia. x 0.125" Thick | 99.9% | Grey to Black | Most Standard Guns | 1 | EJTTIO2304A2 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

4.00" Dia. x 0.125" Thick | 99.99% | Beige to White | Most Standard Guns | 1 | EJTTIO2404A2 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

4.00" Dia. x 0.250" Thick | 99.9% | Grey to Black | Most Standard Guns | 1 | EJTTIO2304A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

4.00" Dia. x 0.250" Thick | 99.99% | Beige to White | Most Standard Guns | 1 | EJTTIO2404A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

6.00" Dia. x 0.250" Thick | 99.9% | Grey to Black | Most Standard Guns | 1 | EJTTIO2306A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

6.00" Dia. x 0.250" Thick | 99.99% | Beige to White | Most Standard Guns | 1 | EJTTIO2406A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

8.00" Dia. x 0.250" Thick | 99.99% | Beige to White | Most Standard Guns | 1 | EJTTIO2408A4 | P.O.R. |

|

Bonded Assemblies Ordering Table

| Material | Description | Target Size | Purity | Bonding Type | Backing Plate Size | Color | Compatible Guns | Notes | Part Number | Price | In Stock | Add To Cart | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Description | Target Size | Purity | Bonding Type | Backing Plate Size | Color | Compatible Guns | Notes | Part Number | Price | In Stock | Add To Cart | |

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

1.00" Dia x 0.125" Thick | 99.9% | Indium | 1.00" Dia x 0.125" Thick | Grey to Black | Most Standard Guns | 1 | EJUTIO2301A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

2.00" Dia x 0.125" Thick | 99.9% | Indium | 2.00" Dia x 0.125" Thick | Grey to Black | Most Standard Guns | 1 | EJUTIO2302A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

2.00" Dia x 0.125" Thick | 99.9% | Elastomer | 2.00" Dia x 0.125" Thick | Grey to Black | Most Standard Guns | 1 | EJUTIO2302E4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

2.00" Dia x 0.125" Thick | 99.9% | Indium | 2.00" Dia x 0.092" Thick | Grey to Black | Standard TORUS 2 | — | EJUTIO2302T4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

2.00" Dia x 0.125" Thick | 99.9% | Elastomer | 2.00" Dia x 0.125" Thick | Grey to Black | TORUS Mag Keeper 2 | 2 | EJUTIO2302TK4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

3.00" Dia x 0.125" Thick | 99.9% | Indium | 3.00" Dia x 0.125" Thick | Grey to Black | Most Standard Guns | 1 | EJUTIO2303A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

3.00" Dia x 0.125" Thick | 99.9% | Elastomer | 3.00" Dia x 0.092" Thick | Grey to Black | Standard TORUS 3 | — | EJUTIO2303ET4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

3.00" Dia x 0.125" Thick | 99.9% | Elastomer | 3.00" Dia x 0.125" Thick | Grey to Black | U.S. Gun | — | EJUTIO2303K4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

3.00" Dia x 0.125" Thick | 99.9% | Indium | 3.00" Dia x 0.092" Thick | Grey to Black | Standard TORUS 3 | — | EJUTIO2303T4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

3.00" Dia x 0.125" Thick | 99.9% | Elastomer | 3.00" Dia x 0.125" Thick | Grey to Black | TORUS Mag Keeper 3 | 2 | EJUTIO2303TK4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

4.00" Dia x 0.125" Thick | 99.9% | Indium | 4.00" Dia x 0.125" Thick | Grey to Black | Most Standard Guns | 1 | EJUTIO2304A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

4.00" Dia x 0.125" Thick | 99.9% | Elastomer | 4.00" Dia x 0.125" Thick | Grey to Black | TORUS Mag Keeper 4 | 2 | EJUTIO2304TK4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

4.00" Dia x 0.125" Thick | 99.9% | Indium | 4.00" Dia x 0.092" Thick | Grey to Black | Standard TORUS 4 | — | EJUTIO2SPL01 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

4.00" Dia x 0.125" Thick | 99.95% | Indium | 4.00" Dia x 0.125" Thick | Grey to Black | Most Standard Guns | 1 | EJUTIO2354A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

1.00" Dia x 0.125" Thick | 99.99% | Indium | 1.00" Dia x 0.125" Thick | Beige to White | Most Standard Guns | 1 | EJUTIO2401A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

2.00" Dia x 0.125" Thick | 99.99% | Indium | 2.00" Dia x 0.125" Thick | Beige to White | Most Standard Guns | 1 | EJUTIO2402A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

2.00" Dia x 0.125" Thick | 99.99% | Indium | 2.00" Dia x 0.092" Thick | Beige to White | Standard TORUS 2 | — | EJUTIO2402T4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

2.00" Dia x 0.125" Thick | 99.99% | Elastomer | 2.00" Dia x 0.125" Thick | Beige to White | TORUS Mag Keeper 2 | 2 | EJUTIO2402TK4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

3.00" Dia x 0.125" Thick | 99.99% | Indium | 3.00" Dia x 0.125" Thick | Beige to White | Most Standard Guns | 1 | EJUTIO2403A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

3.00" Dia x 0.125" Thick | 99.99% | Elastomer | 3.00" Dia x 0.092" Thick | Beige to White | Standard TORUS 3 | — | EJUTIO2403ET4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

3.00" Dia x 0.125" Thick | 99.99% | Elastomer | 3.00" Dia x 0.125" Thick | Beige to White | U.S. Gun | — | EJUTIO2403K4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

3.00" Dia x 0.125" Thick | 99.99% | Indium | 3.00" Dia x 0.092" Thick | Beige to White | Standard TORUS 3 | — | EJUTIO2403T4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

3.00" Dia x 0.125" Thick | 99.99% | Elastomer | 3.00" Dia x 0.125" Thick | Beige to White | TORUS Mag Keeper 3 | 2 | EJUTIO2403TK4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

4.00" Dia x 0.125" Thick | 99.99% | Indium | 4.00" Dia x 0.125" Thick | Beige to White | Most Standard Guns | 1 | EJUTIO2404A4 | P.O.R. |

|

||

| Titanium Dioxide |

TITANIUM DIOXIDE TARGET, |

4.00" Dia x 0.125" Thick | 99.99% | Elastomer | 4.00" Dia x 0.125" Thick | Beige to White | TORUS Mag Keeper 4 | 2 | EJUTIO2404TK4 | P.O.R. |

|