Tantalum (Ta) Sputtering Targets Overview

Our comprehensive offering of sputtering targets, evaporation sources and other deposition materials is listed by material throughout the website. Below you will find budgetary pricing for sputtering targets and deposition materials per your requirements. Actual prices may vary due to market fluctuations. To speak to someone directly about current pricing or for a quote on sputtering targets and other deposition products not listed, please click here.

Tantalum (Ta) General Information

Tantalum is classified as a transition metal on the Periodic Table and is considered to be one of the refractory metals which are highly resistant to corrosion. Tantalum has a melting point of 3,017°C, a density of 16.6 g/cc, and a vapor pressure of 10-4 Torr at 2,590°C. It is metallic grey-blue in color with strikingly similar chemical properties to niobium. It is mainly used to make surgical implants due to its non-toxic nature. It is also used as a capacitor for electronics and may be alloyed with other metals to add strength and durability. Tantalum, along with its alloys and compounds, is evaporated under vacuum to make semiconductors, optical coatings, magnetic storage media, and wear and corrosion resistant coatings.

Tantalum (Ta) Specifications

| Material Type | Tantalum |

| Symbol | Ta |

| Atomic Weight | 180.94788 |

| Atomic Number | 73 |

| Color/Appearance | Gray Blue, Metallic |

| Thermal Conductivity | 57 W/m.K |

| Melting Point (°C) | 3,017 |

| Coefficient of Thermal Expansion | 6.3 x 10-6/K |

| Theoretical Density (g/cc) | 16.6 |

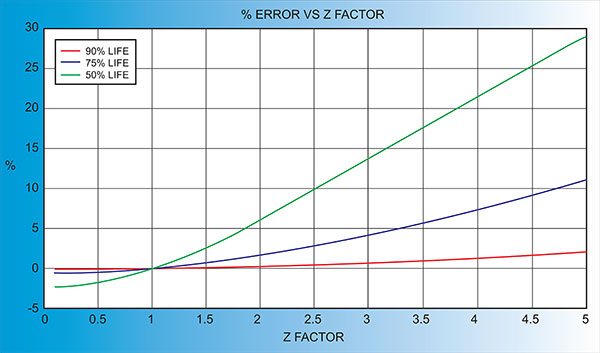

| Z Ratio | 0.262 |

| Sputter | DC |

| Max Power Density (Watts/Square Inch) | 50* |

| Type of Bond | Indium, Elastomer |

| Comments | Forms good films. |

* This is a recommendation based on our experience running these materials in KJLC guns. The ratings are based on unbonded targets and are material specific. Bonded targets should be run at lower powers to prevent bonding failures. Bonded targets should be run at 20 Watts/Square Inch or lower, depending on the material.

* Suggested maximum power densities are based on using a sputter up orientation with optimal thermal transfer from target to the sputter cathode cooling well. Using other sputtering orientations or if there is a poor thermal interface between target to sputter cathode cooling well may require a reduction in suggested maximum power density and/or application of a thermal transfer paste. Please contact techinfo@lesker.com for specific power recommendations.