Germanium (Ge (N-type)) Pieces Overview

We sell these pellets and pieces by unit weight for evaporation use in deposition processes. These approximate materials prices are published to provide budgetary guidelines. Actual prices can vary and may be higher or lower, as determined by availability and market fluctuations. To speak to someone directly about current pricing, please click here .

Germanium (Ge (N-type)) General Information

Germanium is a hard and brittle material with a semi-metallic, grayish-white appearance. It has a density of 5.35 g/cc, a melting point of 937°C, and a vapor pressure of 10-4 Torr at 1,167°C. It is classified on the periodic table as a metalloid, which means it possesses properties of metals and non-metals. Like silicon, germanium is a semiconductor and frequently utilized in the fabrication of transistors and integrated circuits. It is often evaporated under vacuum to create layers in the production of optical storage media and optical coatings. Other uses of the material are as an alloying agent and catalyst.

Germanium (Ge (N-type)) Specifications

| Material Type | Germanium |

| Symbol | Ge (N-type) |

| Atomic Weight | 72.63 |

| Atomic Number | 32 |

| Color/Appearance | Grayish White, Semi-Metallic |

| Thermal Conductivity | 60 W/m.K |

| Melting Point (°C) | 937 |

| Bulk Resistivity | 5-40 ohm-cm |

| Coefficient of Thermal Expansion | 6 x 10-6/K |

| Theoretical Density (g/cc) | 5.32 |

| Dopant | Antimony |

| Z Ratio | 0.516 |

| E-Beam | Excellent |

| Thermal Evaporation Techniques |

Boat: W, C, Ta Crucible: Q, Al2O3 |

| E-Beam Crucible Liner Material | FABMATE®, Graphite |

| Temp. (°C) for Given Vap. Press. (Torr) |

10-8: 812 10-6: 957 10-4: 1,167 |

| Comments | Excellent films from E-beam. |

| Suggested QCM Crystal | Alloy Crystal: 750-1002-G10**** |

**** Suggestion based on previous experience but could vary by process. Contact local KJLC Sales Manager for further information

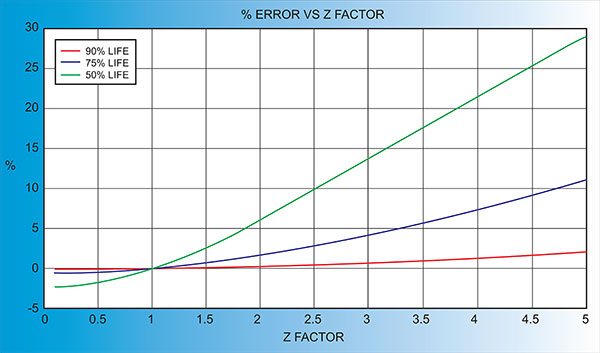

Empirical Determination of Z-Factor

Unfortunately, Z Factor and Shear Modulus are not readily available for many materials. In this case, the Z-Factor can also be determined empirically using the following method:

- Deposit material until Crystal Life is near 50%, or near the end of life, whichever is sooner.

- Place a new substrate adjacent to the used quartz sensor.

- Set QCM Density to the calibrated value; Tooling to 100%

- Zero thickness

- Deposit approximately 1000 to 5000 A of material on the substrate.

- Use a profilometer or interferometer to measure the actual substrate film thickness.

- Adjust the Z Factor of the instrument until the correct thickness reading is shown.

Another alternative is to change crystals frequently and ignore the error. The graph below shows the % Error in Rate/Thickness from using the wrong Z Factor. For a crystal with 90% life, the error is negligible for even large errors in the programmed versus actual Z Factor.

Thermal Evaporation of Germanium (Ge (N-type))

In a deposition system with normal dimensions, a material with an equilibrium vapor pressure (EVP) of 1E-2 Torr will deposit at a rapid rate. Therefore, 1E-2 Torr is typically regarded as the EVP one should attempt to achieve during deposition. The only parameter that affects EVP is temperature. We reference various charts or books to determine what temperature is needed to make the material's EVP 1E-2 Torr. Comparing that temperature with the material's melting point indicates whether the material will evaporate or sublime at that vapor pressure.

Germanium (Ge (N-type)) Vapor Pressure Chart

Germanium's melting point (937°C) is well below the temperature to reach 1E-2 Torr. Hence, germanium evaporates as opposed to subliming. We recommend that the base pressure for germanium evaporation should be 10-6 Torr or lower with an evaporation temperature of 1,400°C. The average deposition rate under these parameters is 1-5 angstroms/sec.

Germanium can be thermally evaporated using a tantalum or tungsten dimple-style boat such as our EVS8B005W or EVS8B005TA. It is not known to alloy with refractory metals.

E-beam Evaporation of Germanium (Ge (N-type))

We recommend using either a graphite® or FABMATE® crucible liner for e-beam evaporating germanium. Sweeping the e-beam and incrementally ramping power to fully melt the evaporation pieces can help improve the deposition rate. Once melted, a focused beam can be used to deposit films.

Crucible liners will need to be replaced fairly often because liquid germanium has the tendency to damage liners. When germanium melts, it will mechanically bond to the inner walls of the crucible liner. Upon cooling or re-heating, the difference in thermal expansion/contraction of the germanium in contact with the liner can produce enough stress to break the liner. We also find that the melt level of a material in the crucible directly affects the success of the crucible liner. Overfilling the crucible will cause the material to spill over and create an electrical short between the liner and the hearth. The outcome is cracking in the crucible. This is the most common cause of crucible liner failure. Placing too little material in the crucible or evaporating too much material before refilling can be detrimental to the process as well. When the melt level is below 30%, the e-beam is likely to strike the bottom or walls of the crucible which immediately results in breakage. Our recommendation is maintain a melt level between 30-80% and slowly ramp power up and down to prevent these complications. However, even when following these guidelines, the liners will still need to be replaced frequently

We recommend that the base pressure for germanium evaporation should be 10-6 Torr or lower with an evaporation temperature of 1,400°C. The average deposition rate under these parameters is 1-5 angstroms/sec. Germanium can also be evaporated directly from the copper hearth of the e-gun. Because not using a crucible liner is not always an option, especially in shared systems, some customers will use a copper crucible liner and place the pieces in the liner as opposed to placing directly in the hearth.

Crucible liners should be stored in a cool, dry place and always handled with gloves or forceps.

See highlighted results that match your result in the table below.

Ordering Table

| More Info | Material | Description | Size | Quantity | Purity | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|---|---|---|

| More Info | Material | Description | Size | Quantity | Purity | Part Number | Price | In Stock | Add To Cart |

| Germanium |

GERMANIUM PIECES, |

3-6mm Pieces | 50g | 99.999% | EVMGE-1038B | P.O.R. |

|

||

| Germanium |

GERMANIUM PIECES, |

3-6mm Pieces | 100g | 99.999% | EVMGE-1038D | P.O.R. |

|

||

| Germanium |

GERMANIUM PIECES, |

3-6mm Pieces | *Per gram (20g min.) | 99.999% | EVMGE50500GM | P.O.R. |

|

||

| Germanium |

GERMANIUM PIECES, |

3-6mm Pieces | 1kg | 99.999% | EVMGE50500KG | P.O.R. |

|

||

| Germanium |

GERMANIUM PIECES, |

3-6mm Pieces | 500g | 99.999% | EVMGE50500T | P.O.R. |

|