Palladium (Pd) Wire Evaporation Materials

Palladium (Pd) Wire Overview

We sell these pellets and pieces by unit weight for evaporation use in deposition processes. These approximate materials prices are published to provide budgetary guidelines. Actual prices can vary and may be higher or lower, as determined by availability and market fluctuations. To speak to someone directly about current pricing, please click here .

Palladium (Pd) General Information

Palladium is a silvery-white precious metal that bears a sharp resemblance to platinum. It has a melting point of 1,554°C, a density of 12.038 g/cc, and a vapor pressure of 10-4 Torr at 1,192°C. It belongs to the platinum group of metals on the periodic table. It has the lowest melting point of the elements of this group and is the least dense. Palladium is remarkably malleable, ductile, and corrosion resistant. Like platinum, its most prominent use in industry is as a catalytic converter. It can also found in jewelry and surgical instruments. Palladium is evaporated under vacuum for the manufacture of semiconductors, sensors, and data storage.

Palladium (Pd) Specifications

| Material Type | Palladium |

| Symbol | Pd |

| Atomic Weight | 106.42 |

| Atomic Number | 46 |

| Color/Appearance | Silvery White Metallic |

| Thermal Conductivity | 72 W/m.K |

| Melting Point (°C) | 1,554 |

| Coefficient of Thermal Expansion | 11.8 x 10-6/K |

| Theoretical Density (g/cc) | 12.02 |

| Z Ratio | 0.357 |

| E-Beam | Excellent |

| Thermal Evaporation Techniques |

Boat: W*** Coil: W Basket: W Crucible: Al2O3 |

| E-Beam Crucible Liner Material | FABMATE®, Graphite, Tungsten |

| Temp. (°C) for Given Vap. Press. (Torr) |

10-8: 842 10-6: 992 10-4: 1,192 |

| Comments | Alloys with refractory metals. |

*** Alumina Coated.

Empirical Determination of Z-Factor

Unfortunately, Z Factor and Shear Modulus are not readily available for many materials. In this case, the Z-Factor can also be determined empirically using the following method:

- Deposit material until Crystal Life is near 50%, or near the end of life, whichever is sooner.

- Place a new substrate adjacent to the used quartz sensor.

- Set QCM Density to the calibrated value; Tooling to 100%

- Zero thickness

- Deposit approximately 1000 to 5000 A of material on the substrate.

- Use a profilometer or interferometer to measure the actual substrate film thickness.

- Adjust the Z Factor of the instrument until the correct thickness reading is shown.

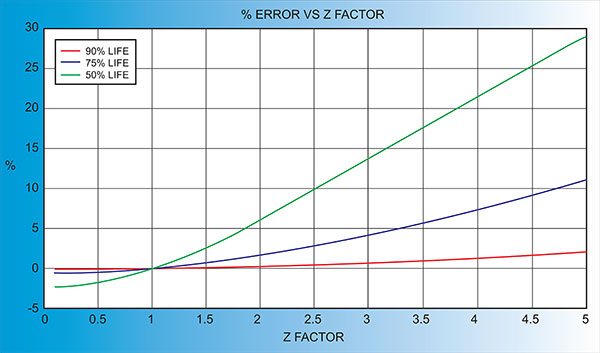

Another alternative is to change crystals frequently and ignore the error. The graph below shows the % Error in Rate/Thickness from using the wrong Z Factor. For a crystal with 90% life, the error is negligible for even large errors in the programmed versus actual Z Factor.

Thermal Evaporation of Palladium (Pd)

Thermally evaporating palladium is difficult, if not impossible, given the capabilities of the vacuum system and power supply available.

Palladium is known for spitting. It is recommended to implement a slow power ramp and soak procedure before opening the shutter to deposit films. Incremental power increases and subsequent holds help to expel any trapped gases and reduce spitting.

Palladium has a vapor pressure of 10-2 Torr at ~1,500°C and is very reactive with refractory metals. Once palladium becomes liquid, it will alloy with and destroy a standard tungsten evaporation boat. We recommend using an alumina-coated tungsten boat such as our EVS9AAOW (if using a KJLC® system) to thermally evaporate palladium. Using this boat, we were able to deposit a film with a thickness of approximately 3,000 angstroms in one run. The power requirements to deposit palladium from our EVS9AAOW are at the upper limit of a single Kepco® power supply. At 100% power, the voltage tops out at 4V and the current is around 230A. Soaks of up to 5 minutes may be required to get the palladium to melt and start depositing.

Evaporating palladium from an alumina-coated boat pushes the limits of the alumina coating. Being that aluminum oxide has a vapor pressure of 10-4 Torr at 1,550°C, and the evaporation temperature of palladium is around 1,500°C, there is the risk of aluminum oxide showing up in deposited films. The probability of aluminum oxide contamination in films is fairly high but to what extent is unknown.

It is also important to note that an EVS9AAOW boat is good for only one deposition run. We've found that the palladium does attack and break the boat when a second run is attempted. Therefore, thermal evaporation results in limited success. E-beam evaporation is the preferred method for depositing palladium.

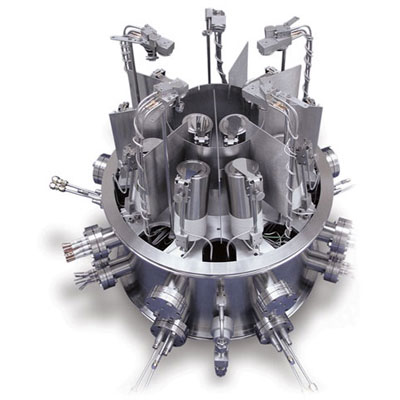

E-beam Evaporation of Palladium (Pd)

E-beam evaporation is the preferred method for depositing palladium as it is rated excellent for this method. Palladium is known for spitting. It is recommended to implement a slow power ramp and soak procedure before opening the shutter to deposit films. Incremental power increases and subsequent holds help to expel any trapped gases and reduce spitting.

We recommend using a FABMATE®, graphite, or tungsten crucible liner for e-beam evaporating palladium. A key process note is to consider the fill volume in the e-beam application because we find that the melt level of a material in a crucible directly affects the success of the crucible liner. Overfilling the crucible will cause the material to spill over and create an electrical short between the liner and the hearth. The outcome is cracking in the crucible. This is the most common cause of crucible liner failure. Placing too little material in the crucible or allowing the melt level to get too low can be detrimental to the process as well. When the melt level is below 30%, the e-beam is likely to strike the bottom or walls of the crucible which immediately results in breakage. Our recommendation is to fill the crucible between 2/3 and 3/4 full to prevent these difficulties.

Crucible liners should be stored in a cool, dry place and always handled with gloves or forceps.

Palladium can also be run directly from the copper hearth of the e-gun. Because of this, some customers prefer to use a pre-machined slug (or starter source) that is directly placed in the hearth pocket. The two main benefits of using a starter source are ease of use and handling as well as superior packing density. Because not using a crucible liner is not always an option, especially in shared systems, some customers will use a copper crucible liner and place the starter source in the copper crucible liner instead of placing directly in the hearth.

KJLC® can produce these starter sources. Contact us by clicking here with your e-gun manufacturer, pocket size, and number of pockets in order for us to produce a quote.

See highlighted results that match your result in the table below.

Ordering Table

| More Info | Material | Description | Size | Quantity | Purity | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|---|---|---|

| More Info | Material | Description | Size | Quantity | Purity | Part Number | Price | In Stock | Add To Cart |

| Palladium |

PALLADIUM WIRE, |

0.020" Dia. | Per ft. | 99.95% | EVMPD35.020 | P.O.R. |

|

||

| Palladium |

PALLADIUM WIRE, |

0.040" Dia. | Per ft. | 99.95% | EVMPD35.040 | P.O.R. |

|