Iron (Fe) Pellets Overview

We sell these pellets and pieces by unit weight for evaporation use in deposition processes. These approximate materials prices are published to provide budgetary guidelines. Actual prices can vary and may be higher or lower, as determined by availability and market fluctuations. To speak to someone directly about current pricing, please click here .

Iron (Fe) General Information

Iron is the most commonly used metal in the world. It is metallic-gray in color, ductile, ferromagnetic, and rusts easily when exposed to oxygen. It has a melting point of 1,535°C, a density of 7.86 g/cc, and a vapor pressure of 10-4 Torr at 1,180°C. Iron is found in a vast array of products including tools, automobiles, and machinery. When alloyed with carbon, steel is created which is an essential component for building construction and automobile manufacturing. Iron also has biological importance as it is responsible for carrying oxygen in blood. It is evaporated under vacuum to form layers in the production of semiconductors, magnetic storage media, and fuel cells, just to name a few.

Iron (Fe) Specifications

| Material Type | Iron † |

| Symbol | Fe |

| Atomic Weight | 55.845 |

| Atomic Number | 26 |

| Color/Appearance | Lustrous, Metallic, Grayish Tinge |

| Thermal Conductivity | 80 W/m.K |

| Melting Point (°C) | 1,535 |

| Coefficient of Thermal Expansion | 11.8 x 10-6/K |

| Theoretical Density (g/cc) | 7.86 |

| Ferromagnetic | Magnetic Material |

| Z Ratio | 0.349 |

| E-Beam | Excellent |

| Thermal Evaporation Techniques |

Boat: W Coil: W Basket: W Crucible: Al2O3 |

| E-Beam Crucible Liner Material | FABMATE®‡ |

| Temp. (°C) for Given Vap. Press. (Torr) |

10-8: 858 10-6: 998 10-4: 1,180 |

| Comments | Attacks W. Films hard, smooth. Preheat gently to outgas. |

| Suggested QCM Crystal | Gold Crystal: KJLCRYSTAL6-G10**** |

† Magnetic material (requires special sputter source).

‡ One run only.

**** Suggestion based on previous experience but could vary by process. Contact local KJLC Sales Manager for further information

Empirical Determination of Z-Factor

Unfortunately, Z Factor and Shear Modulus are not readily available for many materials. In this case, the Z-Factor can also be determined empirically using the following method:

- Deposit material until Crystal Life is near 50%, or near the end of life, whichever is sooner.

- Place a new substrate adjacent to the used quartz sensor.

- Set QCM Density to the calibrated value; Tooling to 100%

- Zero thickness

- Deposit approximately 1000 to 5000 A of material on the substrate.

- Use a profilometer or interferometer to measure the actual substrate film thickness.

- Adjust the Z Factor of the instrument until the correct thickness reading is shown.

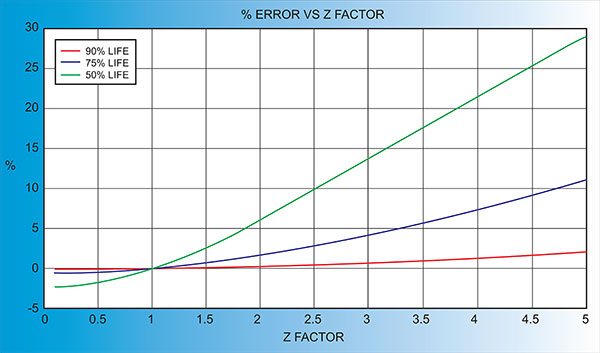

Another alternative is to change crystals frequently and ignore the error. The graph below shows the % Error in Rate/Thickness from using the wrong Z Factor. For a crystal with 90% life, the error is negligible for even large errors in the programmed versus actual Z Factor.

Thermal Evaporation of Iron (Fe)

Thermal evaporation is possible, but challenging, to achieve with iron. E-beam evaporation is the preferred method for depositing iron films.

Liquid iron acts almost as a universal solvent or alloying element. Thermal evaporation is very difficult because the transfer of heat by radiation from heater to crucible and crucible to solid iron, means the temperature of the crucible must be much higher than the iron's temperature. Typically, this will lead to local melting which greatly increases local heat transfer by conduction, and the iron will begin to melt and start to alloy/react with the crucible. For this reason, the recommended way to evaporate iron is by e-beam since the bulk material in contact with the crucible (hearth liner) remains solid.

We have reported limited success evaporating out of a thin-width, thick gauge tungsten boat such as our EVS20A015W. However, these boats are good for only one deposition run and must be replaced frequently. An alumina-coated boat or alumina crucible is not a good choice due to the reactivity of iron.

E-beam Evaporation of Iron (Fe)

The best way to evaporate iron is by electron-beam evaporation as iron is rated "excellent" for this method. FABMATE® is the only crucible liner material recommended for e-beam evaporation of iron. However, these liners are limited to only one run. During evaporation, the iron will melt and adhere to the crucible liner walls. Upon cooling and reheating, if it makes it that far, the difference in thermal contraction and expansion of the iron and the FABMATE® liner will cause immense stress on the liner, causing it to crack.

A key process note is to consider the fill volume of the crucible liner. We find that the melt level of a material in the crucible directly affects the success of the crucible liner. Overfilling the crucible will cause the material to spill over and create an electrical short between the liner and the hearth. The outcome is cracking in the crucible liner. This is the most common cause of crucible liner failure. Placing too little material in the liner or evaporating too much material before refilling can be detrimental to the process as well. When the melt level is below 30%, the e-beam is likely to strike the bottom or walls of the crucible which immediately results in breakage. Our recommendation is to fill the crucible between 2/3 and 3/4 full to prevent these difficulties. However, even when following these fill guidelines, the FABMATE® liner will still fail during cooling.

Crucible liners should be stored in a cool, dry place and always handled with gloves or forceps.

Iron can also be run directly from the copper hearth of the e-gun. Because of this, some customers prefer to use a pre-machined slug (or starter source) that is directly placed in the hearth pocket. The two main benefits of using a starter source are ease of use and handling as well as superior packing density. In order to avoid broken crucible liners, we have had customers install starter sources directly in the hearth.

Because not using a crucible liner is not always an option, especially in shared systems, some customers will use a copper crucible liner and place the starter source in the copper crucible liner instead of placing directly in the hearth.

KJLC® can produce these starter sources. Contact us by clicking here with your e-gun manufacturer, pocket size, and number of pockets in order for us to produce a quote.

See highlighted results that match your result in the table below.

Ordering Table

| More Info | Material | Description | Size | Quantity | Purity | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|---|---|---|

| More Info | Material | Description | Size | Quantity | Purity | Part Number | Price | In Stock | Add To Cart |

| Iron |

IRON PELLETS, |

1/4" Dia. x 1/4" Length | 1 lb. | 99.95% | EVMFE35QXQ | $306.00 |

|

||

| Iron |

IRON PELLETS, |

1/4" Dia. x 1/4" Length | 25 g | 99.95% | EVMFE35QXQA | P.O.R. |

|

||

| Iron |

IRON PELLETS, |

1/4" Dia. x 1/4" Length | 50 g | 99.95% | EVMFE35QXQB | $68.00 |

|

||

| Iron |

IRON PELLETS, |

1/4" Dia. x 1/4" Length | 100 g | 99.95% | EVMFE35QXQD | $83.00 |

|

||

| Iron |

IRON PELLETS, |

1/4" Dia. x 1/4" Length | 200 g | 99.95% | EVMFE35QXQH | $179.00 |

|

||

| Iron |

IRON PELLETS, |

1/4" Dia. x 1/4" Length | 1 kg | 99.95% | EVMFE35QXQKG | P.O.R. |

|

||

| Iron |

IRON PELLETS, |

1/4" Dia. x 1/4" Length | 500 g | 99.95% | EVMFE35QXQT | P.O.R. |

|

||

| Iron |

IRON PELLETS, |

1/4" Dia. x 1/4" Length | 1 lb. | 99.99% | EVMFE40QXQ | P.O.R. |

|

||

| Iron |

IRON PELLETS, |

1/4" Dia. x 1/4" Length | 50 g | 99.99% | EVMFE40QXQB | P.O.R. |

|

||

| Iron |

IRON PELLETS, |

1/8" Dia. x 1/8" Length | 1 lb. | 99.95% | EVMFE35EXE | $545.00 |

|

||

| Iron |

IRON PELLETS, |

1/8" Dia. x 1/8" Length | 25 g | 99.95% | EVMFE35EXEA | $58.00 |

|

||

| Iron |

IRON PELLETS, |

1/8" Dia. x 1/8" Length | 50 g | 99.95% | EVMFE35EXEB | $86.00 |

|

||

| Iron |

IRON PELLETS, |

1/8" Dia. x 1/8" Length | 100 g | 99.95% | EVMFE35EXED | $143.00 |

|

||

| Iron |

IRON PELLETS, |

1/8" Dia. x 1/8" Length | 250 g | 99.95% | EVMFE35EXEJ | P.O.R. |

|

||

| Iron |

IRON PELLETS, |

1/8" Dia. x 1/8" Length | 500 g | 99.95% | EVMFE35EXET | P.O.R. |

|

||

| Iron |

IRON PELLETS, |

1/8" Dia. x 1/8" Length | 100 g | 99.99% | EVMFE40EXED | P.O.R. |

|