Bismuth (Bi) Pieces Evaporation Materials

Bismuth (Bi) Pieces Overview

We sell these pellets and pieces by unit weight for evaporation use in deposition processes. These approximate materials prices are published to provide budgetary guidelines. Actual prices can vary and may be higher or lower, as determined by availability and market fluctuations. To speak to someone directly about current pricing, please click here .

Bismuth (Bi) Specifications

| Material Type | Bismuth |

| Symbol | Bi |

| Atomic Weight | 208.9804 |

| Atomic Number | 83 |

| Color/Appearance | Lustrous Reddish White, Metallic |

| Thermal Conductivity | 8 W/m.K |

| Melting Point (°C) | 271 |

| Coefficient of Thermal Expansion | 13.4 x 10-6/K |

| Theoretical Density (g/cc) | 9.8 |

| Z Ratio | 0.79 |

| E-Beam | Excellent |

| Thermal Evaporation Techniques |

Boat: W, Mo, Ta Coil: W Basket: W Crucible: Al2O3 |

| E-Beam Crucible Liner Material | FABMATE®, Graphite |

| Temp. (°C) for Given Vap. Press. (Torr) |

10-8: 330 10-6: 410 10-4: 520 |

| Export Control (ECCN) | 1C229 |

| Comments | Resistivity high. Low Melting Point materials not ideal for sputtering. |

| Suggested QCM Crystal | Gold Crystal: KJLCRYSTAL6-G10**** |

**** Suggestion based on previous experience but could vary by process. Contact local KJLC Sales Manager for further information

Empirical Determination of Z-Factor

Unfortunately, Z Factor and Shear Modulus are not readily available for many materials. In this case, the Z-Factor can also be determined empirically using the following method:

- Deposit material until Crystal Life is near 50%, or near the end of life, whichever is sooner.

- Place a new substrate adjacent to the used quartz sensor.

- Set QCM Density to the calibrated value; Tooling to 100%

- Zero thickness

- Deposit approximately 1000 to 5000 A of material on the substrate.

- Use a profilometer or interferometer to measure the actual substrate film thickness.

- Adjust the Z Factor of the instrument until the correct thickness reading is shown.

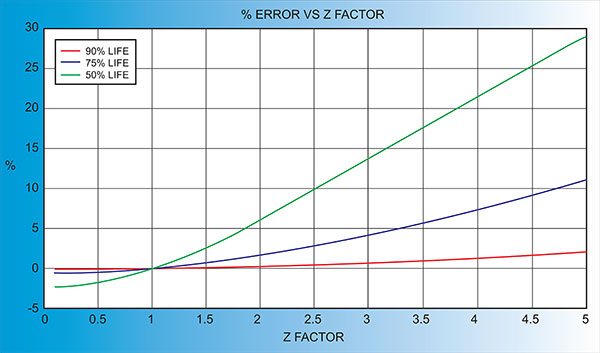

Another alternative is to change crystals frequently and ignore the error. The graph below shows the % Error in Rate/Thickness from using the wrong Z Factor. For a crystal with 90% life, the error is negligible for even large errors in the programmed versus actual Z Factor.

See highlighted results that match your result in the table below.

Ordering Table

| More Info | Material | Description | Size | Quantity | Purity | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|---|---|---|

| More Info | Material | Description | Size | Quantity | Purity | Part Number | Price | In Stock | Add To Cart |

| Bismuth |

EUDF BISMUTH PIECES, |

3mm-6mm Pieces | 25 g | 99.999% | EVMBI2-4MMA | P.O.R. |

|

||

| Bismuth |

EUDF BISMUTH PIECES, |

3mm-6mm Pieces | 50 g | 99.999% | EVMBI2-4MMB | $139.00 |

|

||

| Bismuth |

EUDF BISMUTH PIECES, |

3mm-6mm Pieces | 100 g | 99.999% | EVMBI2-4MMD | $167.00 |

|

||

| Bismuth |

EUDF BISMUTH PIECES, |

3mm-6mm Pieces | 200 g | 99.999% | EVMBI2-4MMH | $268.00 |

|

||

| Bismuth |

EUDF BISMUTH PIECES, |

3mm-6mm Pieces | 250 g | 99.999% | EVMBI2-4MMJ | P.O.R. |

|

||

| Bismuth |

EUDF BISMUTH PIECES, |

3mm-6mm Pieces | 500 g | 99.999% | EVMBI2-4MMT | P.O.R. |

|