Iridium (Ir) Pieces Evaporation Materials

Iridium (Ir) Pieces Overview

We sell these pellets and pieces by unit weight for evaporation use in deposition processes. These approximate materials prices are published to provide budgetary guidelines. Actual prices can vary and may be higher or lower, as determined by availability and market fluctuations. To speak to someone directly about current pricing, please click here .

Iridium (Ir) General Information

Iridium is a rare metal which belongs to the platinum group of elements on the Periodic Table. It has a melting point of 2,410°C, a density of 22.42 g/cc, and a vapor pressure of 10-4 Torr at 2,380°C. It is silvery white in appearance and considered to be very corrosion resistant. Its main application is as a hardening agent for platinum alloys, but it can also be found in devices used in high temperature environments. It is evaporated under vacuum to make particle and surface modification coatings, data storage devices, and fuel cells.

Iridium (Ir) Specifications

| Material Type | Iridium |

| Symbol | Ir |

| Atomic Weight | 192.217 |

| Atomic Number | 77 |

| Color/Appearance | Silvery White, Metallic |

| Thermal Conductivity | 150 W/m.K |

| Melting Point (°C) | 2,410 |

| Coefficient of Thermal Expansion | 6.4 x 10-6/K |

| Theoretical Density (g/cc) | 22.42 |

| Z Ratio | 0.129 |

| E-Beam | Fair |

| Temp. (°C) for Given Vap. Press. (Torr) |

10-8: 1,850 10-6: 2,080 10-4: 2,380 |

Empirical Determination of Z-Factor

Unfortunately, Z Factor and Shear Modulus are not readily available for many materials. In this case, the Z-Factor can also be determined empirically using the following method:

- Deposit material until Crystal Life is near 50%, or near the end of life, whichever is sooner.

- Place a new substrate adjacent to the used quartz sensor.

- Set QCM Density to the calibrated value; Tooling to 100%

- Zero thickness

- Deposit approximately 1000 to 5000 A of material on the substrate.

- Use a profilometer or interferometer to measure the actual substrate film thickness.

- Adjust the Z Factor of the instrument until the correct thickness reading is shown.

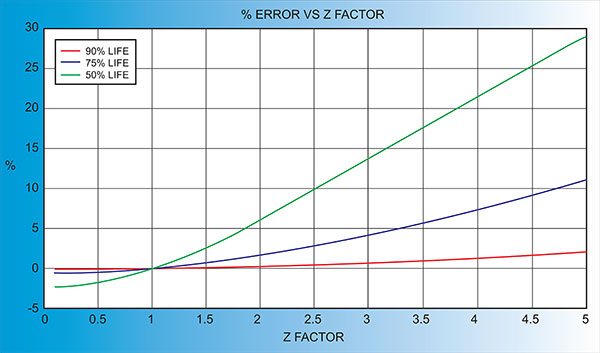

Another alternative is to change crystals frequently and ignore the error. The graph below shows the % Error in Rate/Thickness from using the wrong Z Factor. For a crystal with 90% life, the error is negligible for even large errors in the programmed versus actual Z Factor.

Thermal Evaporation of Iridium (Ir)

Iridium is nearly impossible to deposit by thermal evaporation due to the high power required for the material to evaporate. E-beam evaporation or magnetron sputtering are the recommended methods for iridium deposition.

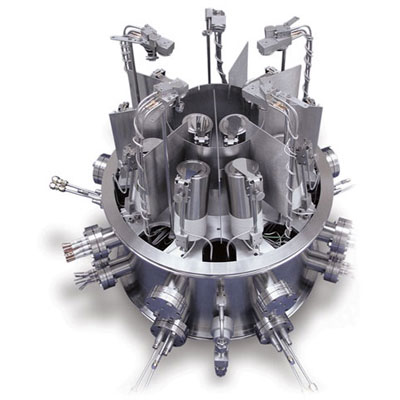

E-beam Evaporation of Iridium (Ir)

Iridium has a vapor pressure of 10-4 Torr at 2,380°C and is rated as 'fair' for e-beam evaporation due to the high temperatures required to achieve a decent deposition rate. We have not yet qualified a crucible liner material for e-beam evaporation of iridium and generally recommend using FABMATE® as it is compatible with many materials.

As with any new material, we recommend doing a manual run to determine the material's melting point and deposition point. Due to iridium's high melting point (2,410°C), high powers are required in order to achieve an effective deposition rate. This will result in the vacuum chamber becoming very hot. Typically, iridium does not melt well to form a solid slug for evaporation. In other words, if the starting material is in pellet form, there is a high risk that even at high powers (>5kW), the pellets will not melt together uniformly which will increase the likelihood of the e-beam burning through the pellets and hitting the crucible. This can be evidenced by a sudden and steep fall-off of the deposition rate. It is then possible for the e-beam to drill a hole through the crucible liner and into the e-gun hearth. For these reasons, the e-beam evaporation of iridium should be closely monitored through at least welder's shade 9 glass. Great care should be taken during the entire evaporation cycle due to the high degree of difficulty and risk of equipment damage.

We recommend using a pre-machined slug (or starter source) instead of pellets. The two main benefits of using a starter source are ease of use and handling as well as superior packing density. We have also found that using a rod for high temperature materials like iridium helps to reduce the amount of power required for deposition. The diameter of the rod is the smallest inner diameter of the crucible liner. The rod is only in contact with the liner on the lower flat which limits thermal conductivity into the hearth. A fixed, focused e-beam should be used and centered directly in the middle of the iridium rod. This will help maximize the deposition rate for a given power. The e-beam should be controlled so that it is focused on the material at all times and the run should be terminated if the e-beam or material is not cooperating.

KJLC® can produce these starter sources or rods. Contact us by clicking here with your e-gun manufacturer, pocket size, and number of pockets in order for us to produce a quote.

See highlighted results that match your result in the table below.

Ordering Table

| More Info | Material | Description | Unit Weight | Purity | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|---|---|

| More Info | Material | Description | Unit Weight | Purity | Part Number | Price | In Stock | Add To Cart |

| Iridium |

IRIDIUM PIECES, |

25g | 99.9% | EVMIR3036A | P.O.R. |

|

||

| Iridium |

IRIDIUM PIECES, |

50g | 99.9% | EVMIR3036B | P.O.R. |

|

||

| Iridium |

IRIDIUM PIECES, |

75g | 99.9% | EVMIR3036C | P.O.R. |

|

||

| Iridium |

IRIDIUM PIECES, |

100g | 99.9% | EVMIR3036D | P.O.R. |

|

||

| Iridium |

IRIDIUM PIECES, |

200g | 99.9% | EVMIR3036H | P.O.R. |

|