By far one of the most common questions that we receive from various users is how to thermally evaporate Aluminum. Aluminum is very commonly evaporated for various applications and can be somewhat problematic. Through some internal experience and through with working with various customers, we recommend two ways to approach thermal evaporation of aluminum.

Thin width, thick gauge, high current tungsten boat

One approach is to use a thin width, thick gauge, high current tungsten boat such as our EVS20A015W. We have been successful with evaporating aluminum in this particular boat and are able to deposit more than 3,000 angstroms per run with rates greater than 30 angstroms per second. We are able to get multiple runs (about 4) with two 1/4" X 1/4" pellets in the boat during each run. Generally, the current draw from the boat is quite consistent run-to-run. It is crucial not to disturb the boat when venting the chamber to re-load with more pellets as the boat becomes brittle after the first evaporation. Even though the boats will need to be replaced frequently (a thicker boat only prolongs inevitable cracking), they are usually inexpensive. However, down-time experienced while switching out the boats should be considered when using this method.

Shielded crucible heater with tall, intermetallic crucible

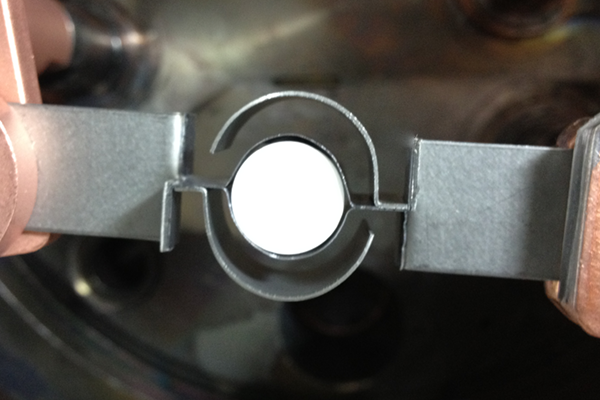

The second recommendation is to use a shielded tantalum crucible heater with a tall intermetallic crucible. Intermetallic crucibles are composed of titanium boride (TiB2) and boron nitride (BN). This material combination works well with aluminum because the material is both lubricious and electrically conductive. The crucible is both strong and conductive, yet its lubricious properties prevent material spill-over and crucible cracking. Great care must be taken when installing the heater to prevent the outer shields from becoming warped which can cause a short in the heater, causing the welded joints to fail. The heater should be centered between the contacts and the outer shielding must be clear of the leads.

Correct - Crucible heater centered, outer shielding clear of leads

Incorrect - Crucible heater off-center, shielding in contact with leads/inner shielding

Some of our production customers have indicated they can get 10-15 runs out of intermetallic crucibles. These users are very experienced in thermally evaporating aluminum in high volumes. Therefore, they have refined their processes so it is possible that these results may not be typical in all applications. An example of a heater-crucible set-up would be our EVCH1 or EVCH10 paired with EVC9INTSPL01 when using one of our vacuum systems.