July 08, 2020 | By KJLC Blog

After an extended shut-down it may be time to re-start your Kurt Lesker built thin film deposition system. A detailed re-start procedure for systems equipped with our eKLipse control software can be found below. This procedure provides a detailed description of the steps required to safely return our deposition systems to full operation.

Read More

Tags:

Systems

Vacuum Science

June 01, 2020 | By KJLC Innovate

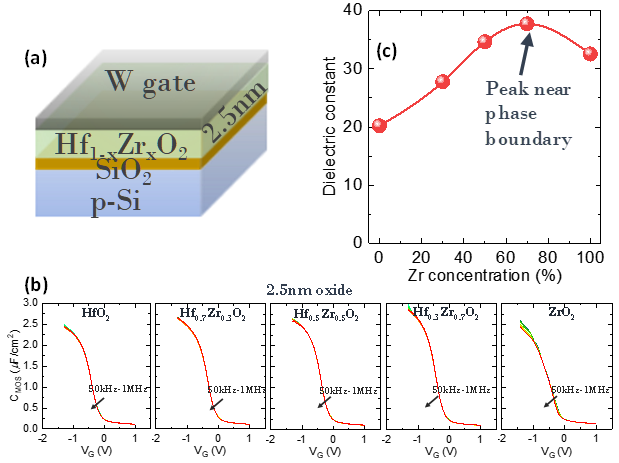

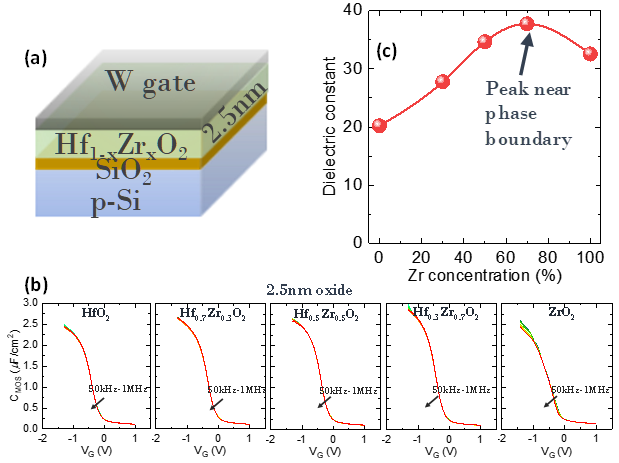

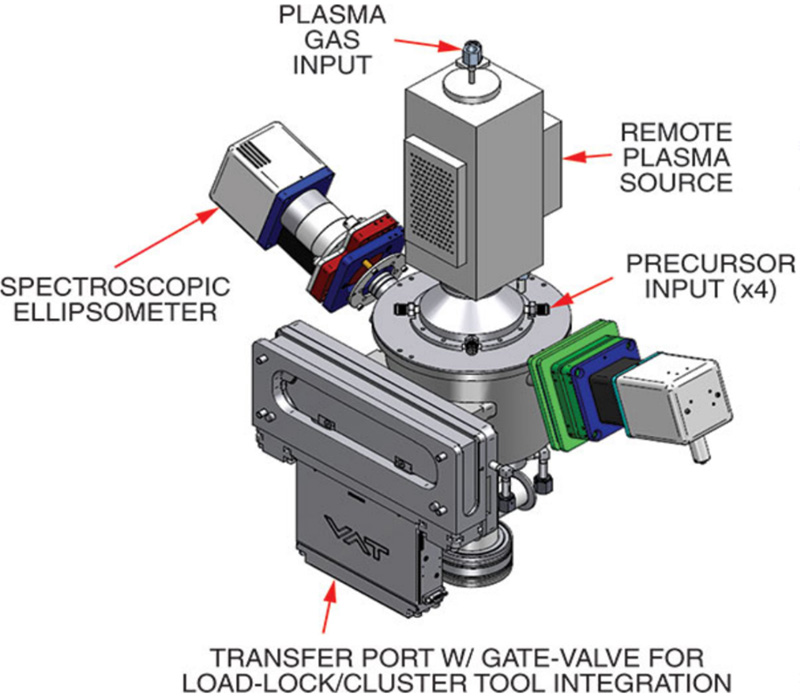

Dr. Kai Ni from the research group of Professor Suman Datta, Stinson Professor of Nanotechnology at the University of Notre Dame, in collaboration with Purdue University and Kurt J. Lesker Company recently developed conformal atomic layer deposition (ALD) based hafnium zirconium oxide thin film processes displaying excellent electrical properties for potential gate oxide complement or replacement in scaled logic and memory technology nodes. The findings were recently published and showcased in the IEEE International Electron Devices Meeting (IEDM) 2019 in San Francisco, CA [ref. 1]. In particular, hafnium zirconium oxide (HfxZr1-xO2, or HZO) has emerged as a ferroelectric (large charge density per unit area) material system that also displays a tunable permittivity or dielectric constant (charge response) depending on the concentration of Zr added to the base HfO2 oxide. The reported films indicate that by sweeping the concentration of Zr in HfO2 during the ALD growth, a substantial boost in the dielectric constant can be observed around 70% Zr concentration due to the presence of a crystallographic phase transition of the underlying HZO material structure, which results in enhanced electrical performance even in ultrathin films 25Å thick [ref. 2]. These findings elucidate the necessity and importance of extremely stringent deposition process control along with corresponding electrical and structural characterization for the understanding of new materials systems for their further implementation in commercial applications such as high-performance digital and analog CMOS technology at advanced nodes.

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Deposition Techniques

May 01, 2020 | By KJLC Blog

In a recently issued patent (US 10,619,950 April 14, 2020) researchers at the Toyota Motor Company have demonstrated that the corrosion resistance of stainless steel exhaust systems for cars and trucks can be substantially improved by heat treatment in high vacuum. Stainless steel is a complex metal alloy of iron, nickel, chrome and other elements. It is known to be a very durable metal but even this robust material can be corroded by exposure to chloride ions, sulfuric and hydrochloric acids, soot and other artifacts of the exhaust from an internal combustion engine. Reaction with these aggressive gases causes pits in steel which eventually lead to premature failure. The use of low-grade fuels speeds the degradation of exhaust systems.

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Deposition Techniques

March 18, 2020 | By KJLC Blog

In these uncertain times, with many people needing to leave their labs for an extended period, it makes sense to review basic shut down procedures for thin film deposition systems. A comprehensive approach to system shutdown may reduce the number of issues related to the eventual re-start. At the Lesker Company we have a team of highly skilled engineers available to assist.

Read More

Tags:

Systems

Vacuum Science

March 06, 2020 | By KJLC Innovate

Dr. Nicholas A. Strnad (General Technical Services, LLC) in collaboration with the U.S. Army Combat Capabilities Command Army Research Laboratory and the University of Maryland, College Park have recently developed conformal processes for a variety of lead-based electronic materials with outstanding properties using atomic layer deposition (ALD)...

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Deposition Techniques

July 22, 2019 | By KJLC Innovate

Sputtering is a relatively mature approach for the deposition of a variety of thin film materials. Initial publications on the process date to the early 1800s. In its simplest form sputtering provides a route to manufacture high quality reflective coatings for mirrors and potato chip bags; and at the extreme end, for creating the most advanced semiconductor computing devices in the world.

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Deposition Techniques

May 09, 2018 | By KJLC Innovate

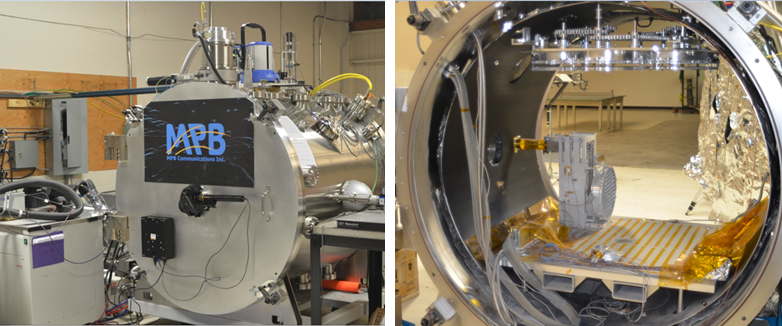

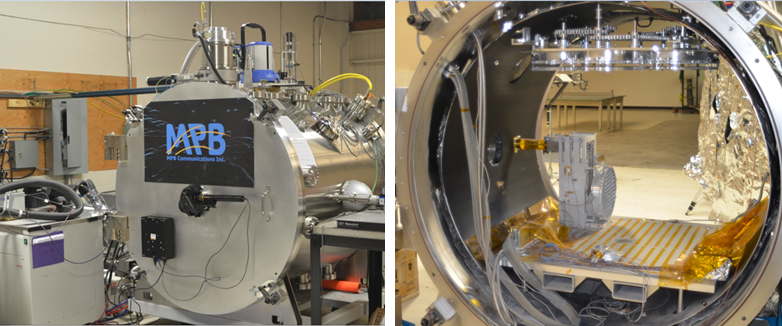

The current push to commercialize space travel has resulted in renewed demand to launch objects and even people into earth orbit or event deep space. Companies including SpaceX, Blue Origin and Rocket Lab have demonstrated the ability to make certain portions of a launch vehicle reusable and that may dramatically alter the cost to get to space. True rocket ship factories are emerging which, in one case, can put out a couple of full blown launch vehicles every month!

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Deposition Techniques

November 28, 2017 | By KJLC Innovate

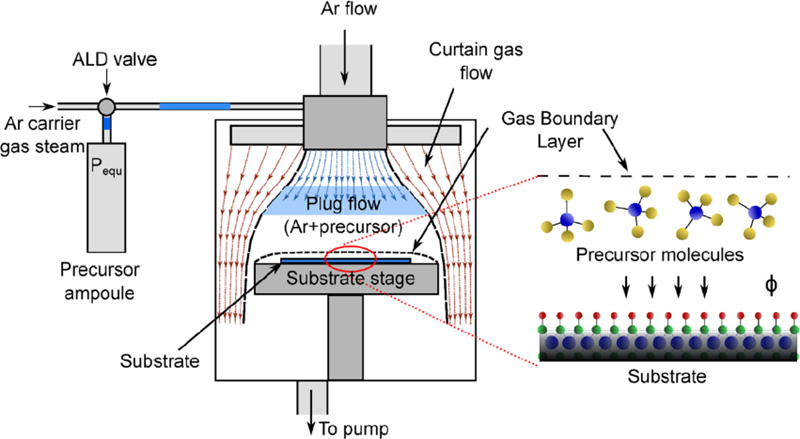

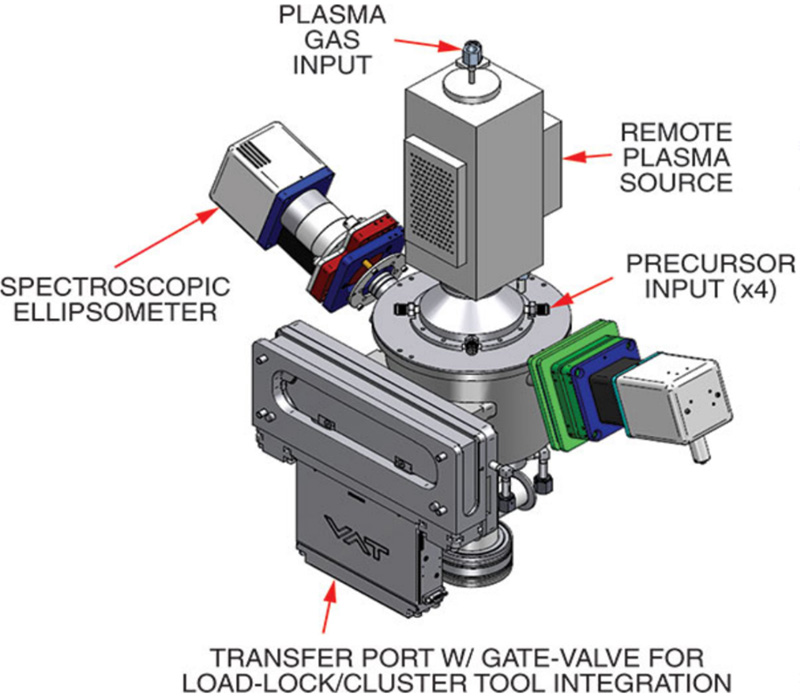

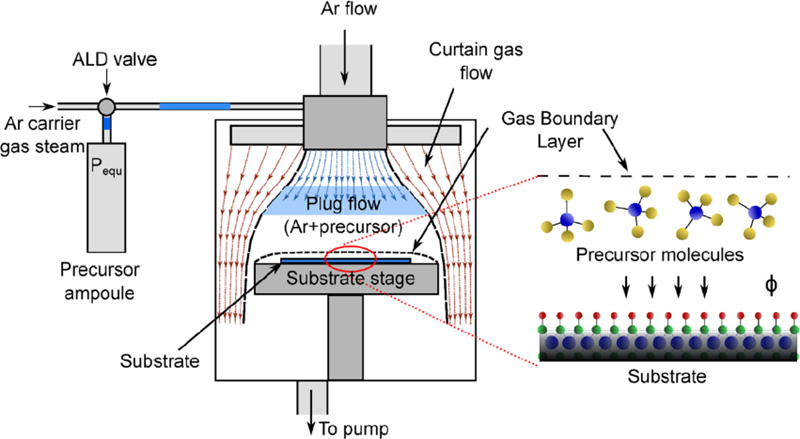

The Kurt J. Lesker Company® (KJLC®), a global manufacturer of vacuum systems, thin film deposition tools and vacuum components, today announced that the United States Patent and Trademark Office has issued US patent number 9,695,510, 'Atomic Layer Deposition Apparatus and Process', covering the design of an atomic layer deposition system and the process to use that system to deposit highly precise and conformal thin films. This proprietary technology substantially reduces the interaction of various precursor gas molecules with the internal surfaces of the reaction chamber and enables actual focusing of gas streams to more effectively coat the surface of arbitrarily large substrates.

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Deposition Techniques

February 20, 2017 | By KJLC Innovate

Next generation vacuum deposition systems must evolve in order to keep pace with the ongoing evolution of thin film materials and devices. Researchers seeking to pursue new areas, such as biomedical devices, 2D materials, specialized magnetics and oxide-based films need new tools to support their work. The frontiers of materials science, particularly at the intersection of biology and thin film deposition, have brought new materials into the vacuum space that were never intended to be there.

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Deposition Techniques

August 30, 2016 | By KJLC Innovate

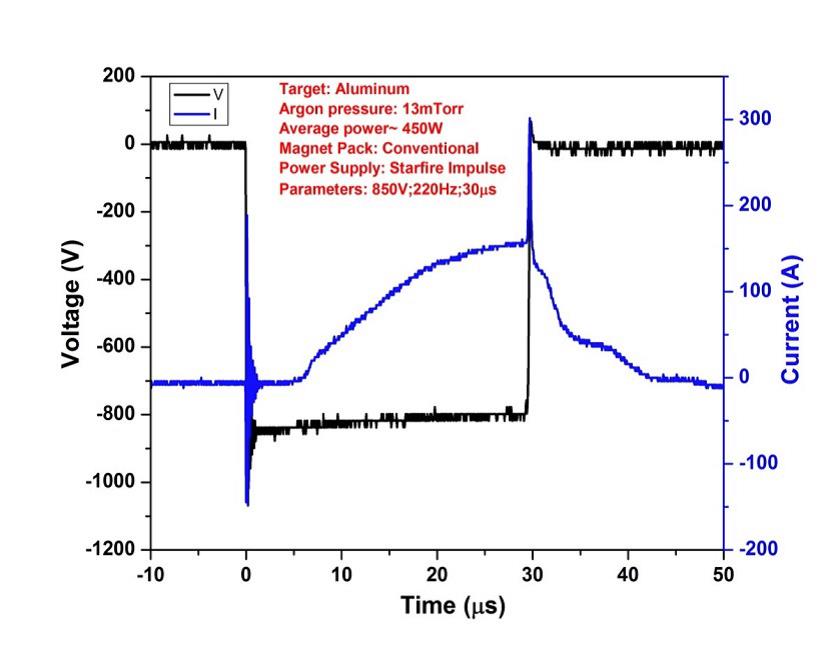

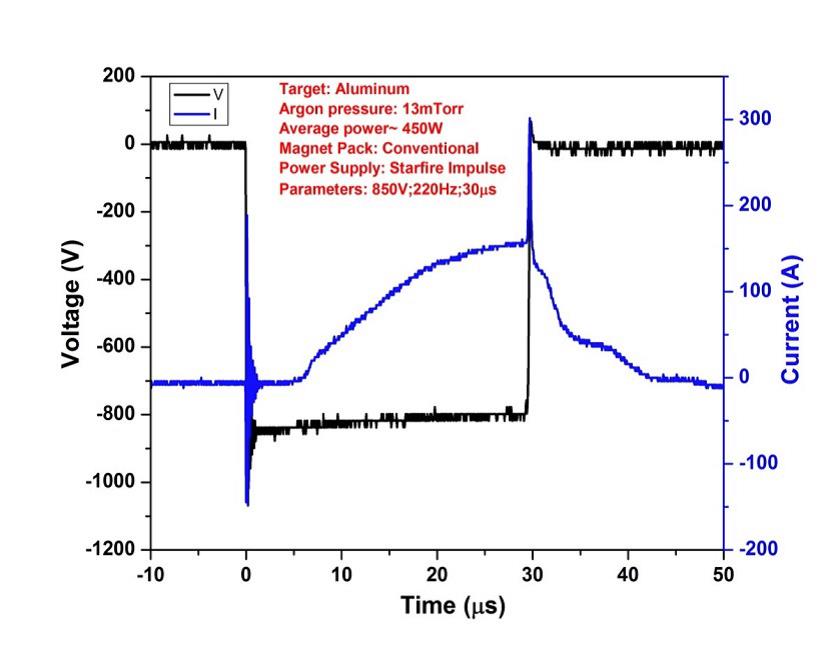

High Power Pulsed Magnetron Sputtering (HPPMS) or High Power Impulse Magnetron Sputtering (HIPIMS) is a type of magnetron sputtering technique where high power pulses of hundreds of microseconds are applied to the magnetron target at frequencies ranging from a few Hz to several kHz.

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Previous Entries

Next Entries