Upgrade or Retrofit Integrated Ferro Magnetic Fluid Rotary Drives in OEM Tools

The Kurt J Lesker Company® offers a full range of Ferro Magnetic Fluid Rotary drives, from manual single axis rotation, to complex multi-axis rotations with integrated motor controls. As such, our offering is perfectly suited to Retrofit or Upgrade an existing tool currently in use in the field. Contact your KJLC representative today to discuss your Retrofit needs.

Popular Examples of systems with integrated Rotary Drives:

- MOCVD

- LPCVD

- Crystallizers

- Implanters

- In-Line sputter systems

- PVD

- Cluster sputtering systems

- Vacuum Furnaces

- Roll to Roll Coaters

Example OEM systems with possible Retrofit opportunity:

- Tokyo Electron

- Applied Materials

- Aixtron

- Varian

- Perkin Elmer

- Von Ardenne

- Meyer Burger

- FHR

Looking for a Quote?

To request a quotation to Upgrade or Retrofit an Integrated Ferro Magnetic Fluid Rotary Drive, please start with our

Retrofit Integrated Ferro Magnetic Fluid Rotary Drive Request Form.

Example Applications and Previous Designs

Complex Rotations

Multiple axes of rotation for complex motions.

As used on a variety of OEM robotic sample manipulation, the KJLC multi-axis rotary motion feedthroughs facilitate complex motions whilst operating at true high vacuum conditions.

Custom Body Solutions

Many rotary drives have temperature, or mechanical, limitations which have direct implications on the process occurring in the vacuum environment. KJLC rotary feedthroughs come with the ability to add active cooling routes for higher temperature applications. The KJLC rotary drive may also be configured in a "cantilevered" design to remove any moving parts (bearings) from the vacuum environment.

Integrated Motor Designs

Many OEM tools utilize separate motors and or pulleys to motorized the rotation for vacuum rotary drives. KJLC offers the ability to integrate the rotary motor into the same body of the feedthrough itself, thus minimizing the atmospheric space the unit takes up and ensuring the best mechanical connection between motor and drive.

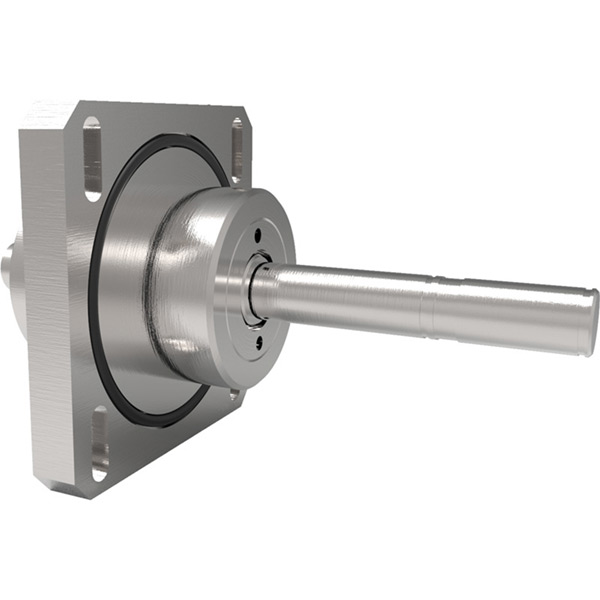

Custom Fabrications

Custom Flange and Shaft options.

Many OEM/Industrial tools come with customized flanges specific to that tool. The KJLC rotary motion feedthroughs can be designed to fit any custom flange or any custom shaft requirements, covering the range from rough vacuums sealing to Ultra High Vacuum sealing.

Preventative Maintenance Alert (Imminent Failure Indicator)

Integrated mechanism for identifying lifetime of rotary drive.

The very nature of rotary motion through a vacuum wall requires the user to perform preventative maintenance to remove the chances of catastrophic failures. However if too strict, the PM cycle may be taking away from valuable uptime. KJLC feedthroughs offer the ability to integrate a Leak detection sensor into the main body of the feedthrough so as to identify when the unit's sealing function has diminished by 50%, ensuring properly scheduled PMs can be performed. Digital and Visiual signals may be output.

Low Weight Customization

Low weight options available.

For tools where preventative maintenance is a constant and on-going practice, the weight that a user must content with is critical. The KJLC rotary feedthrough may be designed with low weight Aluminum bodies (pending application specifics) to drastically decrease the mass of a single unit.