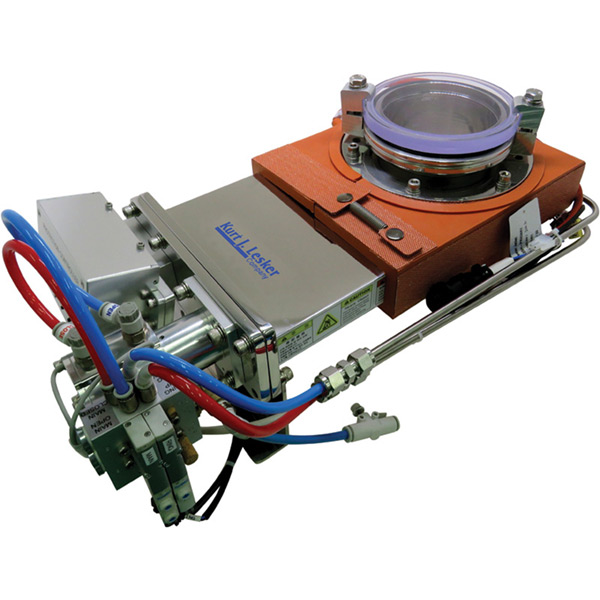

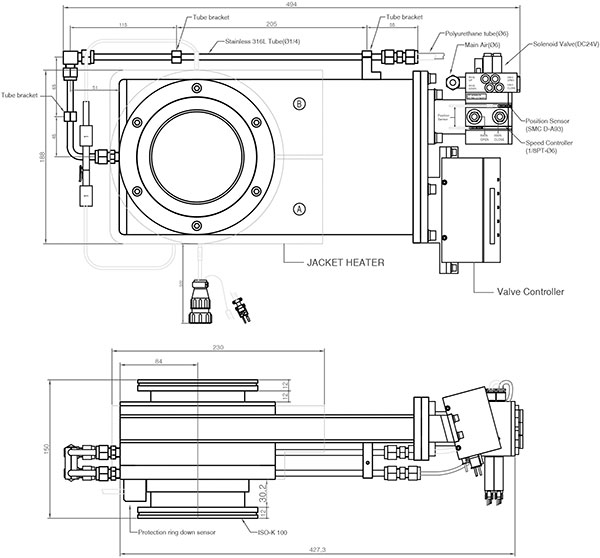

New from Kurt J. Lesker Company-our patented Protection Vacuum Gate Valve's fast action (<0.3 secs to close) protects products that are "in-process" in the event of a vacuum pump failure. This bellows sealed, pneumatic actuated, SS valve system monitors up to four pumps with local or remote control and LCD status display.

The internal mechanism has a low particle generation design and is shielded, in open and closed positions, against particulate accumulation-leading to long life under adverse process conditions

Features

- Fast pneumatic actuation-close in <0.3 seconds

- Patented shielding mechanism

- O-ring sealed actuator

- Long life cycle under adverse process conditions

- Local/remote control with status LCD display

- Easy routine maintenance

- 1, 2, 3, or 4 channel control (on request)

- UPS (on request)

- Separable protection ring down (delayed down time adjustable, on request)

- Heat jacket (on request)

Applications

For vacuum pump or chamber isolation in demanding processes:

- Plasma etching, cleaning, and desmearing

- CVD processes (including MO, PE, HDP, LP, and AP)

- Nanotechnology processes with high particulate levels

- Thin film photovoltaic panels

Specifications Table

| Pressure Range (torr) | 1.0 x 10-6 ~ 12 x 105 Pa (abs) |

| Differential Press (torr) | Opening Direction: 0.12MPa Closing Direction: 0.12MPa |

| Max ΔPress Before Open (torr) | 0.005MPa |

| Material | Bellows: STS 316L Gate (seat): STS 304, AL6061 Valve housing, Bonnet, Shaft (Stem), Bellows end piece: STS 304 Bonnet seal, Pneumatic seal: FKM (Viton®) Gate seal, Vacuum seal: FKM (Viton®), FFKM (Kalrez®) on request |

| Leak Rate (cc/sec) | Housing: <1.0 x 10-10 PA* m3/sec Seat (Gate): <1.3 x 10-10 PA* m3/sec (±) |

| Bakeout Limit. (°C) | Body: 105°C (Viton® o-ring) | 150°C (FFKM o-ring) Actuator: 60°C |

| Mounting | Horizontal |