Overview

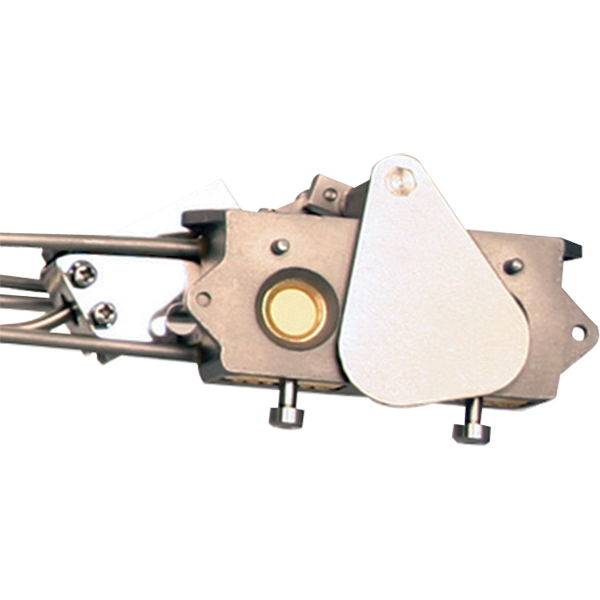

INFICON UHV Bakeable Crystal Sensors offer proven reliability and durability and have the best thermal stability of any sensor head on the market. Made from 304 Stainless Steel, Molybdenum, Inconel, Nickel, and Alumina materials, the UHV Bakeable Sensor is designed to withstand continuous bakeout temperatures up to 450° C (for bakeout only, water flow required for actual deposition monitoring). The front load design allows for easy insertion of the crystal holder in applications lacking sufficient room for side insertion.

Each sensor comes completely assembled and includes integral water tubes, in-vacuum coaxial cable (Front Load) or in-vacuum conduit (Cool Drawer), water tube bending tool, crystal snatcher (Front Load), and operating instructions. All air and water tubes (except the bakeable sensor) are 1/8 inch (0.32cm) O.D. All shuttered sensors require the 750-420-G1 pneumatic control valve. Limited use with other controllers is possible call KJLC +1 800 245 1656 or click here to contact us with any technical questions.

Features

- High temperature braze & welded construction

- Bakeout temperatures to 450° C

- Crystal shutter (option)

- Front load crystal holder

- Easy installation

- CF40 feedthrough

- No brazing or welding to feedthrough required

- Sensor/feedthrough combination welded to customer specified lengths

Specifications

| Type | Bakeable Sensor w/ Shutter | Bakeable Sensor w/out Shutter |

|---|---|---|

| Maximum temperature | 400° C continuous (for bake only; water flow recommended for actual deposition monitoring) | 450° C continuous (for bake only; water flow recommended for actual deposition monitoring) |

| Sensor head size (maximum envelope) | 1.35" x 1.38" x 1.21" high (34 mm x 35 mm x 31 mm high | 1.35" x 1.38" x 0.94" high (34 mm x 35 mm x 24 mm high) |

| Crystal exchange | Front loading, self-contained package for ease of exchange. Cam-type locking handle allows easy removal and good thermal contact. Pneumatically operated shutter flips up for easy crystal exchange. | Front loading, self-contained package for ease of exchange. Cam-type locking handle allows easy removal and good thermal contact. |

| Mounting | a) Standard-four #4-40 tapped holes on the back of the body b) Optional-right angle bracket; IPN 007-108 |

Four #4-40 tapped holes on the back of the body |

| Feedthrough | 2.75" ConFlat®, integral with sensor head. Water, air and coax tubes are semi-rigid, but easily formed (2.0" [50.8 mm] minimum bend radius) | 2.75" ConFlat, integral with sensor head. Water and coax tubes are semi-rigid, but easily formed. (2.0" [50.8 mm] minimum bend radius) |

| Utilities | 1) Minimum water flow 150-200 cc/min, 30° C max. (Do not allow to freeze.) (Customer should provide means of easily disconnecting the 0.25" water tubes during bakeout.) 2) Filtered, oil-free air, regulated at 80 PSIG (5.5 bar) [552 kPa] 3) Solenoid valve, 750-420-G1, 24 VAC or VDC, or equivalent valve required |

Minimum water flow 150-200 cc/min, 30° C max. (Do not allow to freeze.) (Customer should provide means of easily disconnecting the 0.25" water tubes during bakeout.) |

| Materials | ||

| Body and holder | 304 type stainless steel | 304 type stainless steel |

| Springs | Molybdenum and Inconel X-750 | Molybdenum and Inconel X-750 |

| Water, air and coax lines | 0.125" (3 mm) O.D. water and air x 0.015" (0.4 mm) wall thickness seamless 304 stainless steel; 0.188" (5 mm) O.D. coax | - |

| Other mechanical parts | 18-8 or 304 stainless | 18-8 or 304 stainless |

| Insulators | >99% Al2O3 in vacuum; other high density ceramics used elsewhere | >99% Al2O3 in vacuum; other high density ceramics used elsewhere |

| Wire | 1) Ni (in vacuum) 2) Ni plated Cu (elsewhere) |

1) Ni (in vacuum) 2) Ni plated Cu (elsewhere) |

| Braze | Vacuum process high temperature Ni-Cr alloy | Vacuum process high temperature Ni-Cr alloy |

| Crystal | 0.550" (13.97 mm) diameter | 0.550" (13.97 mm) diameter |

Configuration Options

Ordering Code Example: BK-A0F-10

| Type of Sensor (Includes crystal snatcher and user manual. Crystals sold separately) |

Code | Configuration |

| Standard (water lines parallel to crystal face) |

A | A |

| Shutter Assembly (see note 3) |

Code | Configuration |

| None | 0 | 0 |

| Standard shutter | 1 | |

| Length of Sensor (see note 1) |

Code | Configuration |

|

Standard length: Shuttered sensors: 17-99 cm (28-39") Non-shuttered sensors: 10-99 cm (28-39") *** Sensor lengths over 71 cm (28") are subject to an additional charge as well as 2-4 weeks additional lead time. |

F | F |

| Welded Sensor Length (see notes 1 and 2) |

Code | Configuration |

| Weld length in centimeters, 10-70 cm (4-27.5") | 10-70 | 10 |

| Weld length in centimeters, 71-99 cm (28-39") | 71-99 |