“Best” Gauge

We are frequently asked, “Which is the best gauge for my application?” In the words of a famous philosopher, it all depends on what you mean by “best.” The first consideration is the pressure range you wish to measure. There are many different types of gauge and each type has a specific pressure range, or dynamic range limit.

For example, the most common type of Bayard-Alpert gauge (BAG) will operate up to 10-4 torr and down to ~10-9 torr. So, its pressure range, 10+5 torr has the same value as its dynamic range and this device might be looked on as limited by its pressure range. By contrast, a capacitance manometers have a useful range that spans from perhaps 25,000 torr to 10-5 torr. But each sensor head operates over a dynamic range of 10+4. That is, to measure any pressure within the complete range requires a number of sensor heads because the dynamic range of each head is less than the pressure range.

Selecting the Pressure Range

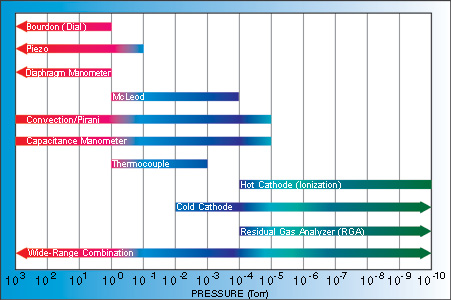

A chart, such as the one reproduced here, gives the pressure range covered by the various types of gauges. First select the gauge that covers the lowest pressure you wish to measure. If that gauge's highest pressure is above your upper limit, you need just one gauge. But if it cannot reach your upper limit, you may need two (even three?) separate gauge types, or more than one sensing head (as with a capacitance manometer).

Selecting for Accuracy/Reproducibility

The accuracy/repeatability of gauges is frequently misunderstood. Most users simply install a new gauge and treat the pressure indication as an absolute truth. Without getting too detailed, all vacuum gauges (except capacitance manometers and diaphragm gauges) have different response factors to different gases. The safest policy is to regard any gauge, straight from the box, as having doubtful accuracy and repeatability and to accept that it must be calibrated before it can be believed (Again, except capacitance manometers and diaphragm gauges and even those gauges require occasional re-calibration).

An excellent reference on gauge calibration is “Total Pressure Measurements in Vacuum Technology” by Armand Berman. We recommend it every time someone calls in with the famous gotcha, such as: “I have two identical gauges from your company, looking at the same chamber pressure and showing different readings.”

Selecting for Application

Low Pressure: In the general high vacuum range around 10- 6 torr, either the Penning gauge or the Bayard-Alpert gauge (BAG) are chosen. The Penning is also known by the descriptive name cold cathode since it has no hot filament. This has advantages when using weird gases that might damage a filament.

The hot filament BAG is available with either tungsten (W) or thoria-coated iridium (ThOIr) filaments. Often, ThOIr filaments are used because they “don't burn out.” That is, if the vacuum system suddenly went to atmosphere while the gauge was on, the filament would not burn out. I can't comment on the validity of this idea since every time I've dumped a vacuum system to atmosphere, gauge filaments were pretty low on my list of priorities. But when using high partial pressures of oxygen or oxygen containing compounds, a ThOIr filament with its oxidized surface and lower working temperature are definitely recommended over tungsten. This is in contrast with the choice of filaments used in the halogen gases (fluorine, chlorine, etc) or halogen containing gases. The ThOIr is quickly poisoned by halogens and stops emitting. Tungsten is definitely preferred for the latter application but not for oxygen. If your application involves plasma cleaning with CF4 and O2, use a Penning gauge.

Neither BAGs nor Penning gauges are wonderfully accurate or stable. They need frequent calibration if you want to believe the pressure reading or want repeatability over a period longer than one day.

Intermediate Pressure: If you are sputtering in the millitorr range, at least consider a Schulz-Phelps ion (S-P) gauge. They are about as accurate as BAGs but neatly cover the pressure range used in sputtering. One curious point, not many vacuum suppliers carry control electronics for S-P gauges (and that comment includes us).

If you want accurate pressure indication and regulation in the sputter pressure range — or in any pressure range from ~10-4 torr up — use a capacitance manometer. A well-known manufacture claims accuracies (as percentage of reading) of ±0.25% to ±0.5% for their least accurate gauges. You do have keep them at constant temperature, but that is a small price to pay for the accuracy and compatibility with any gas that is stable with Inconel (and most are).

Foreline Pressure: While capacitance manometers are “best” in this pressure range, they are also the most expensive gauges. The lowest priced gauge for this range is a thermocouple (TC), which with an analog indicator, costs $200 to $300. But you must accept, as far as accuracy is concerned, that you get what you paid for. A TC gauge reading might be within a factor of 5 (either side) of the true pressure. Calibration improves that a bit but a TC never comes close to capacitance manometer. Thermocouple gauges are fairly rugged, low-cost devices that give pressures accurate enough to allow pump cross-over and indicate the “state” of a foreline.

Digital Pirani gauges have accuracies typically ±3 times the lowest pressure they can measure. For example, a gauge measuring down to 1 mtorr has an accuracy of ±3 mtorr. While that may not look good at the bottom of the pressure range, at the top (2 torr for this particular gauge) it is quite accurate — much better than a thermocouple gauge. In addition, since Pirani's platinum alloy sensing elements are less susceptible to contamination (from pyrolyzed hydrocarbon vapors) than the thermocouple's tungsten wire, and the Pirani's reproducibility is much better, gauge calibration makes sense. Pirani gauges are available with different lower pressure limits ranging from 10-2 to 10-5 torr, each gauge giving (roughly) a dynamic range of 104

High Pressures: One interesting gauge combines two sensing elements: a Pirani and a diaphragm sensor. The diaphragm is not unlike a capacitance manometer in design but it uses strain gauges (not capacitance) to measure the diaphragm's deflection. The combined gauge, called the Wide Range, covers pressures from 1 mtorr to 1500 torr with good accuracy ±2 torr above 2 torr and ±3 mtorr below 2 torr. This gauge is ideal for all processes requiring gas backfilling of most gases.