Alumina Coated Micro-Electronic Sources

Overview

Alumina coated evaporation sources have been developed to replace alumina crucibles for some specific applications. The advantages of this type of evaporation source is good heat transfer and the inertness of alumina with most metals. Also, the evaporant does not wet the alumina resulting in no resistant change of the boat when the evaporant melts. Due to the non wetting characteristics of alumina, the evaporant forms a sphere when melted resulting in a point source. This type of evaporation source will give long life compared to the non protected sources. Coated sources will require from thirty to fifty percent more power to effect an evaporation do to the difference in heat conduction. The alumina is semi-conductor grade and is applied to the boat or basket by a plasma spray technique. Temperatures of 1850°C should be avoided, and when an evaporation is effected the power should be reduced slightly to avoid over heating.

Please Select a Category:

Boats

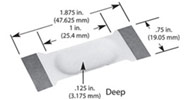

Narrowed Trough

| More Info | Reference | No. Per Pack | Volt | Amps | Watts | Temp. | Description | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|---|---|---|---|---|

| More Info | Reference | No. Per Pack | Volt | Amps | Watts | Temp. | Description | Part Number | Price | In Stock | Add To Cart |

| Molybdenum | 5 | 0.86 | 151 | 130 | 1200°C | MOLYBDENUM SOURCE,AL203 COATED 1 7/8" X 3/4" X 1/8" DEEP,5/PK | EVSME3AOMO | $71.00 |

|

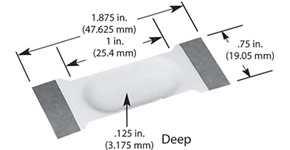

Dimple

| More Info | Reference | No. Per Pack | Volt | Amps | Watts | Temp. | Description | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|---|---|---|---|---|

| More Info | Reference | No. Per Pack | Volt | Amps | Watts | Temp. | Description | Part Number | Price | In Stock | Add To Cart |

| Molybdenum | 5 | 0.83 | 116 | 96 | 1200°C | MOLY SOURCE, ALUMINA COATED 1 7/8"L X 1/2"W, 5/PKG | EVSME4AOMO | $60.00 |

|

Inverted Top-Hat Dimple

| More Info | Reference | No. Per Pack | Volt | Amps | Watts | Temp. | Description | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|---|---|---|---|---|

| More Info | Reference | No. Per Pack | Volt | Amps | Watts | Temp. | Description | Part Number | Price | In Stock | Add To Cart |

| Molybdenum | 5 | 0.84 | 106 | 89 | 1200°C | ALUMINA COATED MOLYBDENUM SOURCE, 1 7/8"L X 1/2"W, 5/PKG | EVSME6BAOMO | $61.00 |

|

Inverted Top-Hat Trough

| More Info | Reference | No. Per Pack | Volt | Amps | Watts | Temp. | Description | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|---|---|---|---|---|

| More Info | Reference | No. Per Pack | Volt | Amps | Watts | Temp. | Description | Part Number | Price | In Stock | Add To Cart |

| Molybdenum | 5 | 0.80 | 83 | 66 | 1200°C | MOLY SOURCE,ALUMINA COATED,5PK 1 7/8"L X 3/4"W X 1/8"DEEP-1" | EVSME9AOMO | $73.00 |

|

Heaters Covers

Cover for Box Heater (EVSME22BAO)

| More Info | No. Per Pack | Description | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|

| More Info | No. Per Pack | Description | Part Number | Price | In Stock | Add To Cart |

| 1 | ALUMINA COTD BOAT SOURCE,.005 COVER BOTH SDS-1/4"HOLE,1/PKG | EVSME22AAO | $49.00 |

|

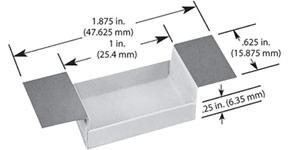

Box Heater

| More Info | Reference | No. Per Pack | Volt | Amps | Watts | Temp. | Description | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|---|---|---|---|---|

| More Info | Reference | No. Per Pack | Volt | Amps | Watts | Temp. | Description | Part Number | Price | In Stock | Add To Cart |

| Alumina-Coated Tantalum | 1 | 1.3 | 259 | 337 | 1200°C | ALUMINA COATED BOAT SOURCE,.010 1-7/8"L X 5/8"W X 1"D, 1/PKG | EVSME22BAO | P.O.R. |

|

Cover for Box Heater (EVSSB3AOTA)

| More Info | No. Per Pack | Description | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|

| More Info | No. Per Pack | Description | Part Number | Price | In Stock | Add To Cart |

| 1 | ALUMINA COATED TANTALUM BOX COVER,2" L X 3/4" W X 3/8" ,1/PKG | EVSSB3AAOTA | P.O.R. |

|

Box Heater

| More Info | Reference | No. Per Pack | Volt | Amps | Watts | Temp. | Description | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|---|---|---|---|---|

| More Info | Reference | No. Per Pack | Volt | Amps | Watts | Temp. | Description | Part Number | Price | In Stock | Add To Cart |

| Alumina-Coated Tantalum | 1 | 1.54 | 295 | 454 | 1200°C | ALUMINA COATED TANTALUM BOX 2 1/16" L X3/4" W X 3/8" DEEP, 1PK | EVSSB3AOTA | $127.00 |

|

Cover for Box Heater (EVSSB5AO)

| More Info | No. Per Pack | Description | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|

| More Info | No. Per Pack | Description | Part Number | Price | In Stock | Add To Cart |

| 1 | TANTALUM COVER, ALUMINA COATED 3/8" CENTER HOLE, 1/PKG | EVSSB5AAOTA | $62.00 |

|

Box Heater

| More Info | Reference | No. Per Pack | Volt | Amps | Watts | Temp. | Description | Part Number | Price | In Stock | Add To Cart |

|---|---|---|---|---|---|---|---|---|---|---|---|

| More Info | Reference | No. Per Pack | Volt | Amps | Watts | Temp. | Description | Part Number | Price | In Stock | Add To Cart |

| Alumina-Coated Tantalum | 1 | 2.2 | 314 | 691 | 1200°C | ALUMINA COATED SOURCE, .010 TA 3" OVERALL LENGTH, 1/ PKG. | EVSSB5AO | $152.00 |

|