April 11, 2018 | By KJLC Innovate

Researchers Dr. André Anders and Dr. Yuchen Yang have expanded on their previous imaging work on linear magnetron cathodes. In their most recent work, titled “Plasma studies of a linear magnetron operating in the range from DC to HIPIMS,” the authors put forth additional information on the evolution and movement of spokes with several deposition materials and discharge conditions.

Read More

Tags:

INNOVATE

Vacuum Science

November 28, 2017 | By KJLC Innovate

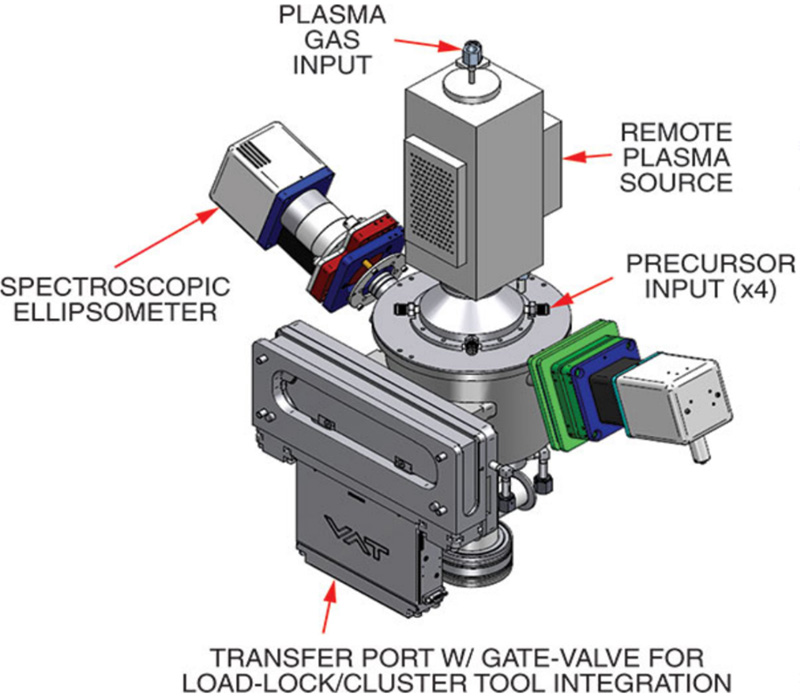

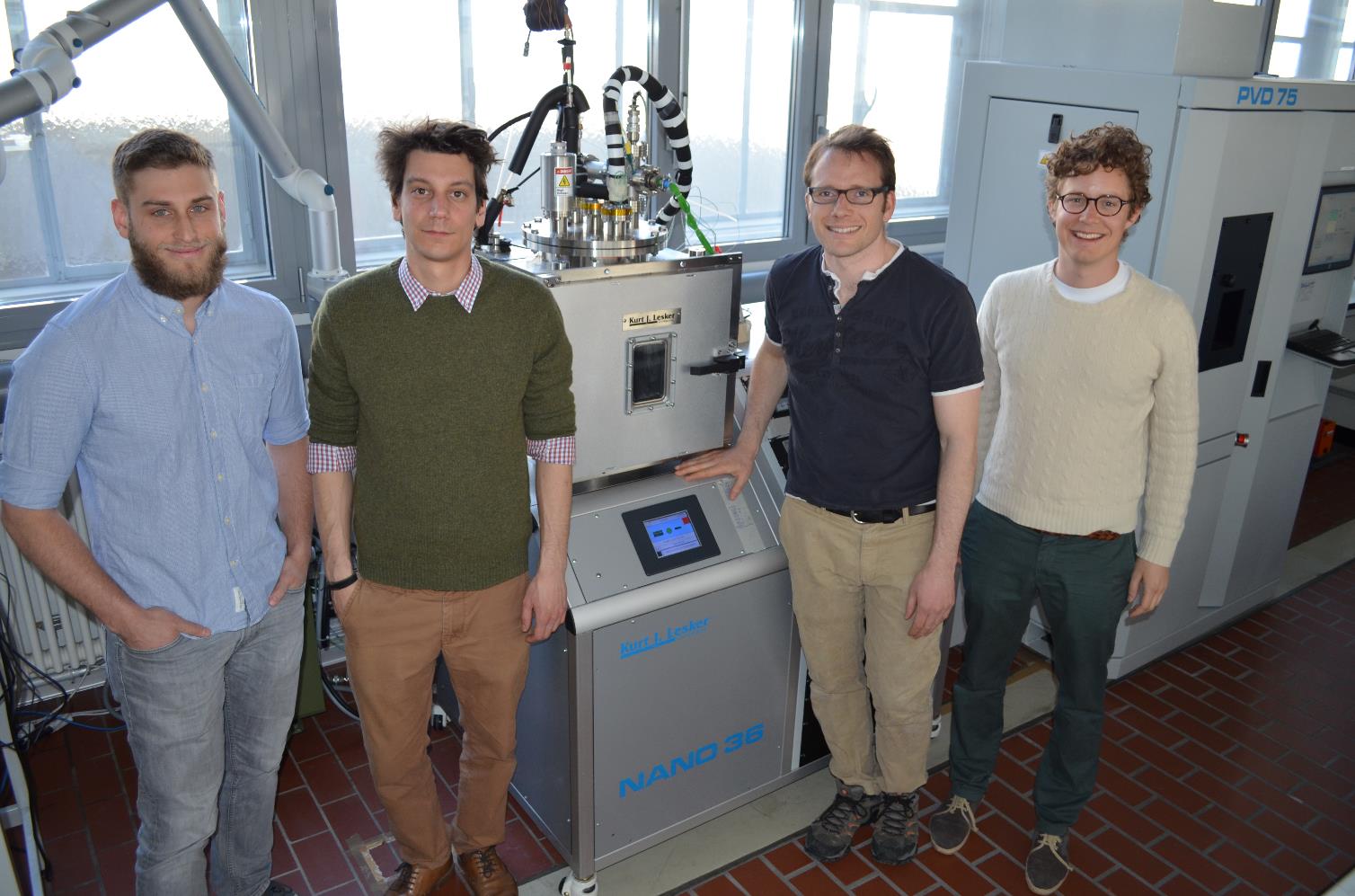

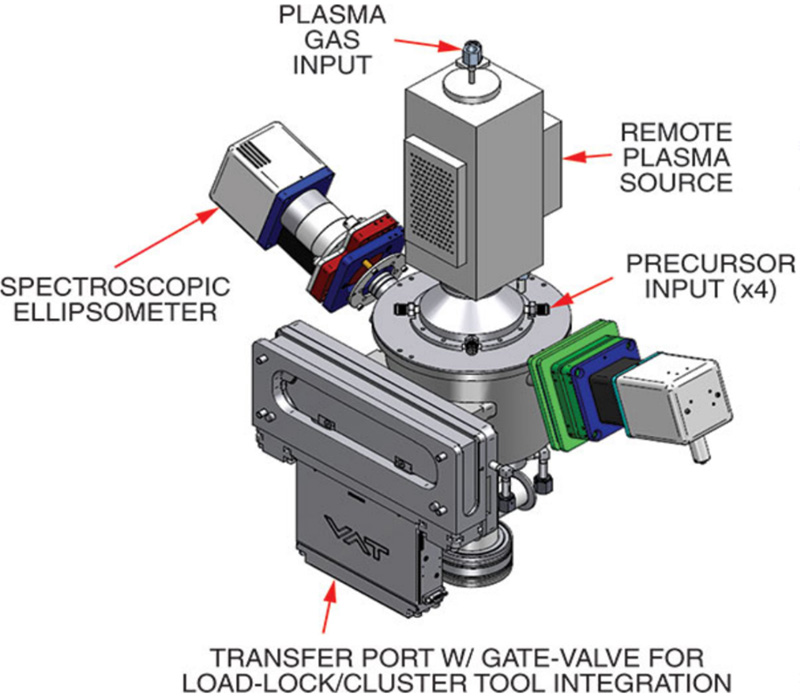

The Kurt J. Lesker Company® (KJLC®), a global manufacturer of vacuum systems, thin film deposition tools and vacuum components, today announced that the United States Patent and Trademark Office has issued US patent number 9,695,510, 'Atomic Layer Deposition Apparatus and Process', covering the design of an atomic layer deposition system and the process to use that system to deposit highly precise and conformal thin films. This proprietary technology substantially reduces the interaction of various precursor gas molecules with the internal surfaces of the reaction chamber and enables actual focusing of gas streams to more effectively coat the surface of arbitrarily large substrates.

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Deposition Techniques

October 25, 2017 | By KJLC Innovate

In a July 2017 publication, Drs. André Anders and Yuchen Yang provide an enhanced description of the flows and energy of electrons at the face of a magnetron sputter cathode. By combining a unique imaging process and a linear cathode (target) the researchers were able to generate a series of time/space images which shows plasma instabilities driven by the motion of electrons, within the cathode's magnetic field. The images show the effects on plasma flow for both conventional DC magnetron sputtering (dcMS) and also high power impulse magnetron sputtering (HiPIMs). The full paper is available on line at http://aip.scitation.org/doi/10.1063/1.4994192.

Read More

Tags:

INNOVATE

Vacuum Science

Deposition Techniques

February 20, 2017 | By KJLC Innovate

Next generation vacuum deposition systems must evolve in order to keep pace with the ongoing evolution of thin film materials and devices. Researchers seeking to pursue new areas, such as biomedical devices, 2D materials, specialized magnetics and oxide-based films need new tools to support their work. The frontiers of materials science, particularly at the intersection of biology and thin film deposition, have brought new materials into the vacuum space that were never intended to be there.

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Deposition Techniques

August 30, 2016 | By KJLC Innovate

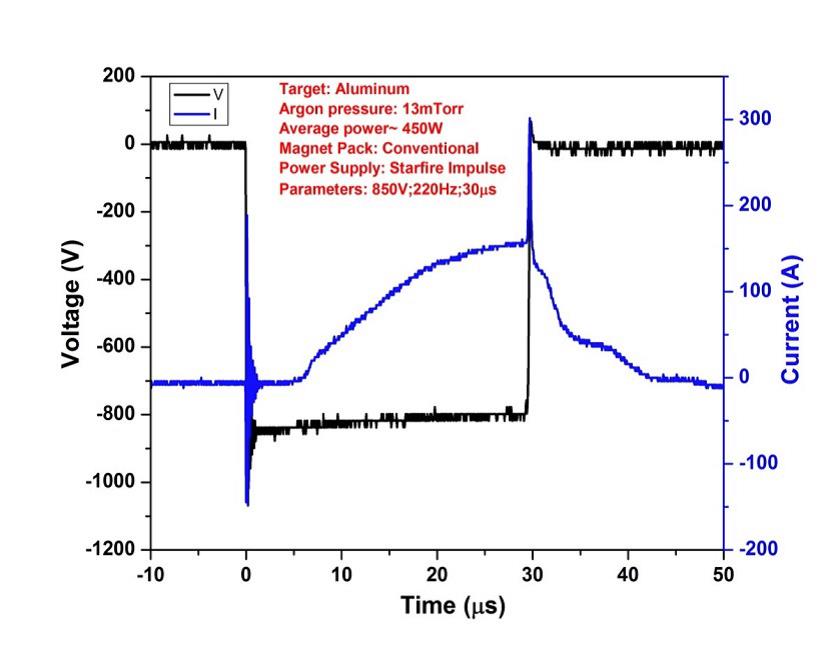

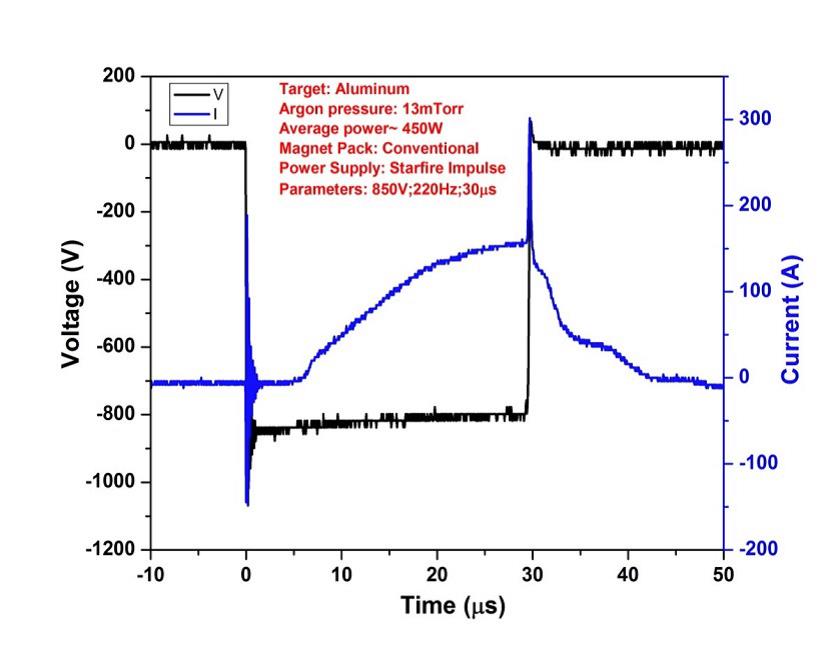

High Power Pulsed Magnetron Sputtering (HPPMS) or High Power Impulse Magnetron Sputtering (HIPIMS) is a type of magnetron sputtering technique where high power pulses of hundreds of microseconds are applied to the magnetron target at frequencies ranging from a few Hz to several kHz.

Read More

Tags:

INNOVATE

Systems

Vacuum Science

July 20, 2016 | By KJLC Innovate

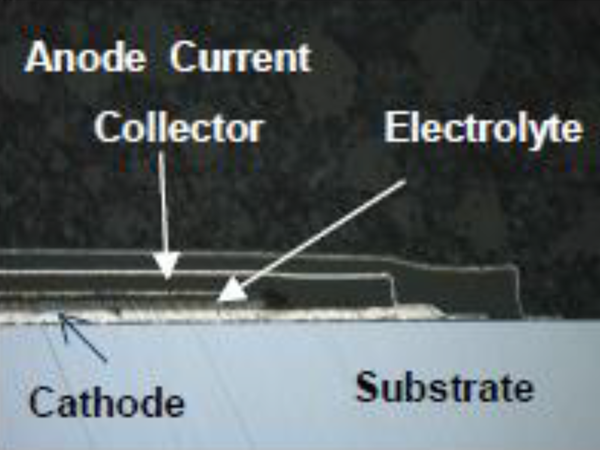

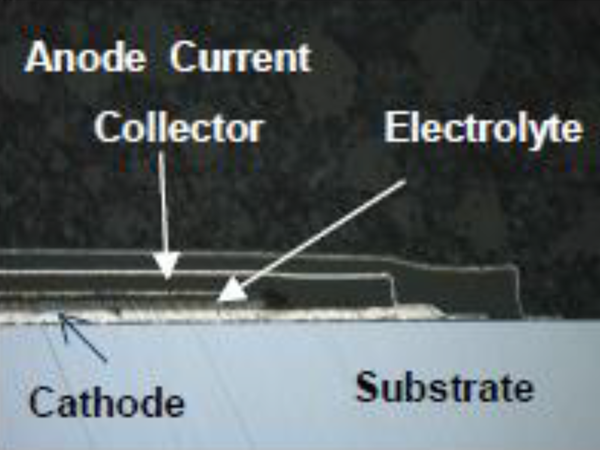

The concept of energy storage in thin films has been around for a long time. One of the early uses of the term 'Thin Film Battery' (TFB) was in a 1976 patent by Exxon [1]. Nearly 20 years later, Bates and his team at Oak Ridge National Laboratory (ORNL) patented the sputter-based, all solid state battery utilizing the electrolyte LiPON [2]. The Bates battery paired LiCoO2 and Li3PO4-xNx (LiPON) to produce a 4 volt secondary cell.

Read More

Tags:

INNOVATE

May 13, 2016 | By KJLC Innovate

Solar cells work by using materials that absorb photons from sunlight in a broad spectral range and in turn effectively convert this captured light into free charges that produce electricity. Modern solar cells are based on crystalline Silicon (c-Si) which is a cheap and abundant semiconductor, however the cost to produce electricity using them is relatively high as the efficiency rates of c-Si based cells are relatively low. As a result thin film solar cells have been developed to combat crystalline Silicon's inherent inefficiencies. Technologies such as CIGS, CdTE, amorphous Silicon and OPV have all strived to create solar cells that have high efficiencies coupled with good cell stability and low manufacturing costs.

Read More

Tags:

INNOVATE

Systems

Vacuum Science

May 09, 2016 | By KJLC Innovate

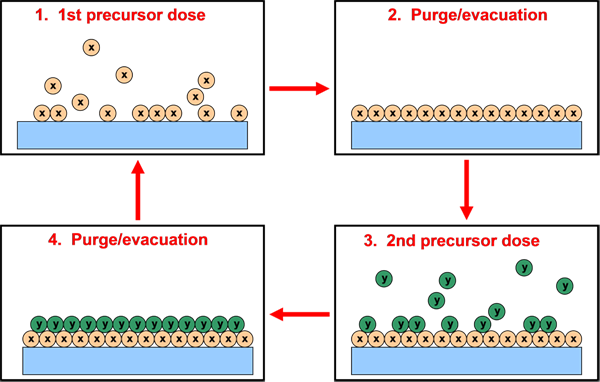

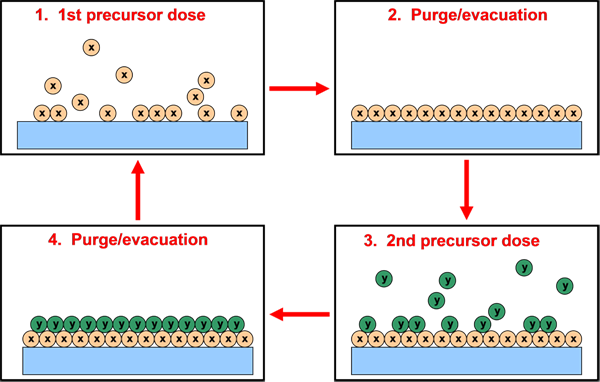

ALD has been described as a thin film deposition technology that can keep the semiconductor industry on track per Moore's law (or observation) [1] for a few more years. In its most ideal form, it is a process that enables monolayer, or sub-monolayer growth of certain materials through the sequential exposure of a functionalized substrate to a pair of precursor gases. If dosed correctly the gases attach at specific surface sites and react to create a near perfect film on the order of a few angstroms thick. Presently the U.S. Department of Defense anticipates that the last process node for semiconductor devices (the end of Moore's) is 7 nm and will be achieved by 2020 [2].

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Deposition Techniques

January 19, 2016 | By KJLC Innovate

Combinatorial Magnetron Sputtering (CMS) has distinguished itself as a viable tool for the rapid development of vast libraries of complex materials. Researchers at the Joint Center for Artificial Photosynthesis, California Institute of Technology (Cal Tech) and the Kurt J. Lesker Company® (KJLC®) [1] have recently published work on Combinatorial Magnetron Sputtering (CMS) using a novel robotically controlled thin film deposition cathode tilt and substrate manipulation mechanism. Combinations of metal alloys, mixed metal oxides and nitrides have been demonstrated with the system as a basis for a predictive model developed by Cal Tech to streamline the design of new materials for certain critical applications.

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Deposition Techniques

July 29, 2015 | By KJLC Innovate

Plasmonics is an important field of research with applications in bio-sensing, photocatalysis, solar cells and high-speed computing, among others. The fundamental technologically enabling features of plasmonics are sub-wavelength confinement of electromagnetic fields and ultra-strong enhancement of those fields. Highly-reflective metals are the predominant material choice for plasmonic devices. More specifically, Gold and Silver have been the most studied materials to date. Aluminum and Copper are burgeoning plasmonic materials which offer CMOS compatibility and low cost. Furthermore, Aluminium opens up the possibility of ultraviolet plasmonic devices which have recently been shown to have applications in bio-sensing and colour filters.

Read More

Tags:

INNOVATE

Systems

Vacuum Science

Previous Entries

Next Entries