The Kurt J. Lesker Company (KJLC) has supported organic electronics research since producing its first dedicated PVD tool series over 20 years ago, enabling many breakthrough results. Recently a team from CNR NANOTEC (Lecce, Italy) has reported a strategy to improve the stability and durability of flexible top-emitting organic light-emitting diodes in their paper "Flexible distributed Bragg reflectors as optical outcouplers for OLEDs based on a polymeric anode", with results obtained using both KJLC deposition tools and materials.[1]

Organic light-emitting diodes (OLEDs) are one of the major success stories in recent scientific history, becoming the preferred display technology for televisions and mobile devices within just 30 years of initial discovery, and with a rapidly increasing $30B+ market size.[2] A standard OLED stack geometry takes a "bottom-emission" approach where a transparent substrate material is used (such as glass or polymer film) along with a transparent bottom electrode. This allows for an opaque, highly reflective top electrode to be used, such as a thick metal film, with the light emission occurring through the substrate. Although this geometry is well suited to standard displays, with the substrate also acting as a protective layer to the delicate organic materials, the choice of substrate material is heavily restricted. Top-emission OLEDs (TOLEDs) can overcome this problem; by using an opaque, reflective bottom electrode and a (semi)transparent top electrode, substrate choice becomes almost arbitrary, opening up interesting possibilities to incorporate OLEDs on textiles (for wearable displays) or other pre-manufactured parts. Additionally, substrate outcoupling losses can be reduced, and thin-film transistor (TFT) arrays (used for driving the pixels in an AMOLED display) can be simplified.

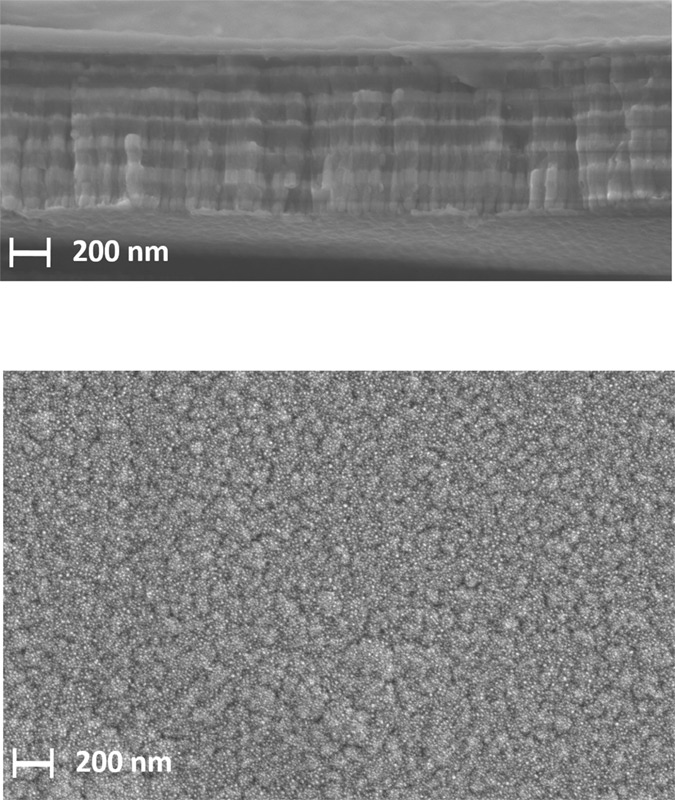

Typically, TOLEDs have been produced using metal films as bottom electrodes as they provide both the reflectivity and conductivity required, however these films are not durable under mechanical deformation so are not well suited to flexible devices.[3] An alternative electrode structure is required to realise a durable, flexible TOLED. The CNR NANOTEC researchers replaced the metal film bottom electrode with a distributed Bragg reflector (DBR) structure coupled to a conductive polymer layer, using a 50μm polyimide flexible substrate. A DBR is a type of optical stack structure consisting of pairs of dielectric layers with contrasting refractive indices which results in a highly efficient, wavelength-tuneable dielectric mirror. In this case, alternating sputtered layers of TiO2 and SiO2 were used to form the DBR. As with all optical stacks, film thickness control was critical to achieve optimal performance - in the case of a DBR the thickness (d) of each layer must be equal to one-quarter of the desired peak reflectance wavelength (i.e. d = λ/4n, where λ is the peak reflectance vacuum wavelength and n is the refractive index of the material). To tune the DBR to the emission wavelength of their selected green OLED device, the researchers used seven pairs of 54nm TiO2 and 91nm of SiO2 films.

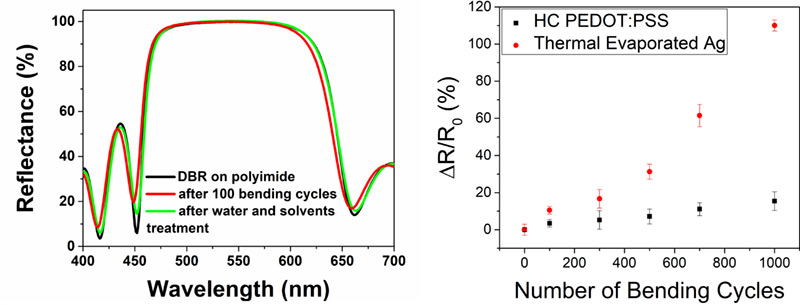

This DBR structure was tested for reflectivity using optical spectroscopy and showed a peak reflectance of 99.9% at 540nm, and a stop-band width of 200nm, consistent with the dielectric layer thicknesses produced and ideally suited to the green emission of the OLED device. After capping with the conductive polymer layer (PEDOT:PSS, produced by spin-coating) the electrode structure was tested for mechanical durability over 1000 bending cycles to a 2.5mm radius of curvature. The DBR/PEDOT structure showed just a 15% increase in electrical resistance, compared to >100% for a typical thermally evaporated silver (Ag) layer, a significant improvement in durability.

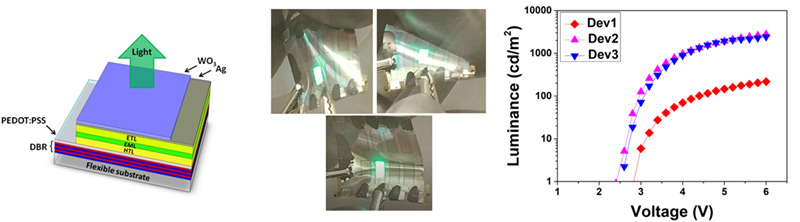

A standard green OLED device stack, using Ir(ppy)3 as the emitter material, was then deposited via thermal evaporation onto the DBR/PEDOT electrode to test the performance of the device. The top-electrode consisted of a thin, semi-transparent Ag layer capped with WO3. Although the Ag layer was thin enough to provide reasonable transmittance, the high refractive index mismatch between it and the organic layers still resulted in significant reflection back into the device, forming a microcavity (a structure where an optical medium - in this case the organic layers - is trapped between two reflecting electrodes). Because of this microcavity effect, an OLED device with typically thin doped transport layers (20nm each) showed poor luminance of just 200 cd/m2. The researchers recognised that the outcoupling of light from such a microcavity structure was highly dependant on the length of the cavity (i.e. the total thickness of the organic layers), with cavity lengths of λ/2n and higher multiples (where λ is the emission wavelength and n is the refractive index of the organic stack) being optimal. To better achieve this condition, the doped transport layers were increased in thickness in order to tune the total cavity length - in doing so the luminance could be improved to 3000 cd/m2 for an optimised stack, demonstrating the importance of careful stack optimisation and accurate deposition control in these complex optical structures.

The structures were produced on a custom KJLC cluster tool consisting of separated sputtering and organic processing chambers.

All images © the authors of "Flexible distributed Bragg reflectors as optical outcouplers for OLEDs based on a polymeric anode", Journal of Information Display (https://doi.org/10.1080/15980316.2020.1825537).

References

[1] C. T. Prontera, M. Pugliese, R. Giannuzzi, S. Carallo, M. Esposito, G. Gigli & V. Maiorano, "Flexible distributed Bragg reflectors as optical outcouplers for OLEDs based on a polymeric anode", Journal of Information Display, 2020 (https://doi.org/10.1080/15980316.2020.1825537)

[2] IDTechEx, "Flexible, Printed OLED Displays 2020-2030: Forecasts, Markets, Technologies", (https://www.idtechex.com/en/research-report/flexible-printed-oled-displays-2020-2030-forecasts-markets-technologies/693)

[3] X. Luo, B. Zhang & G. Zhang, "Fatigue of metals at nanoscale: Metal thin films and conductive interconnects for flexible device application", Nano Materials Science, 1(3), 2019, 198 (https://www.sciencedirect.com/science/article/pii/S2589965119300030)