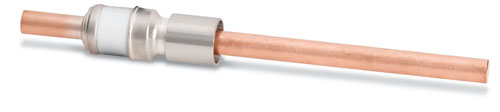

Power Feedthroughs

Power feedthroughs have one or multiple conductors penetrating the vacuum wall to carry electricity to any powered vacuum device. Each conductor is sealed to an electrical insulator that, in turn, is sealed to a weldable flange or baseplate coupling.

The insulator can be any material suitable for the application's voltage isolation, vacuum level, and temperature extremes. The most common insulator is alumina, which is UHV-compatible, has high dielectric strength, and a temperature range from -196°C to 450°C. Occasionally, phenolic and PTFE insulators are satisfactory for high-current/low-voltage applications in rough- and high-vacuum conditions.

Gas Discharges

A feedthrough's maximum voltage rating is determined in air at one atmosphere pressure. For reasons beyond the scope of these Notes, different gases can have very different breakdown voltages (BVs). For example, a paper from Rensselaer Polytechnic shows helium's BV is roughly half air's BV, for some given conditions.

As a gross generalization, the simpler the gas's structure, the lower its BV. The atomic inert gases, particularly helium, have a low BV under most backfill pressures. Complex gas molecules have high BVs and tend to quench discharges which is why SF6 is used in transmission power line switches and breakers.

The conductor metals (Cu, Ni, SS, etc.) are available in wire, rod, or tube form. The last is often used to power a device that also needs gas or liquid flow through it.

Conductor material selection is typically based on current ratings, corrosion resistance, and magnetism:

| Current Rating | Corrosion Resistance | |

| Copper | High | Low |

| Stainless Steel | Low | Medium |

| Nickel | Medium | High |

When choosing power feedthroughs, the important criteria are maximum operating voltage, maximum current per conductor, base pressure requirements, and the working environment (i.e., backfill gas pressure, composition of gas, etc.). While voltage, current, base pressure, and temperature are usually easy to specify, the working environment may be difficult (see Gas Discharges).

Never under-specify either voltage or current because arcing, melting, or insulator cracking could result.