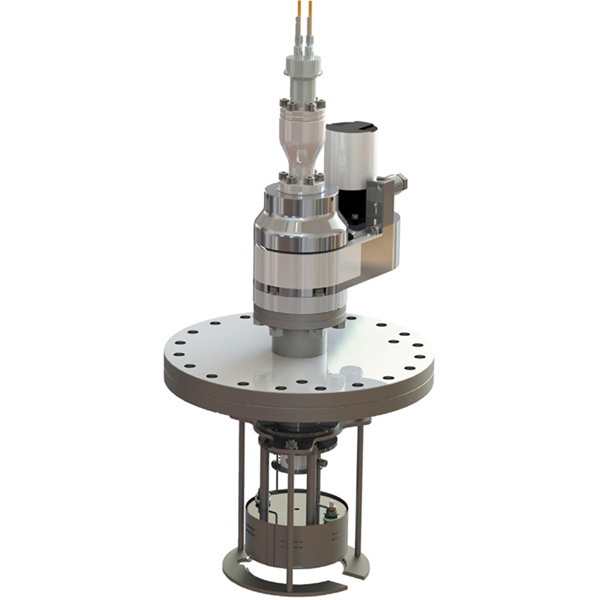

EPS Series - Substrate Preparation Stage

Substrate parallel to plane of mounting flange

Overview

- 2" or 4" substrates

- Substrate heating to 800°C

- Substrate rotation to 60rpm

- 50mm height adjustment

- Manual and motorized actuation

The EPS series of in-line preparation stages support the substrate parallel to the mounting flange. The stationary EPS heating module provides durable and uniform heating of 2" or 4" substrates to 800°C with Molybdenum heat shields provided to minimize heat loss. A Type K thermocouple is provided as standard.

Manual or motorized substrate rotation to 60rpm is provided by the magnetically-coupled MagiDrive rotary drives. Eliminating unnecessary bellows and dynamic seals from the EPS ensures true UHV performance and increases reliability.

In addition to substrate rotation, the 50mm height adjustment option allows the substrate position to be optimized via manual or motorized actuation. The EPS series of preparation stages provide cost-effective and durable sample preparation capability. For higher temperature heating, DC/RF biasing or additional capabilities see the EC-I series.

Series Options

- Heating to 800°C

- Heating to 800°C

- Substrate rotation option (motorised)

- Heating to 800°C

- Substrate rotation (motorised)

- 50mm height adjustment option (manual)

Stage Configuration: EPS Series

| STANDARD CONFIGURATION | ||||

| Substrate Size | 50mm (2") | 100mm (4") | ||

| Mounting Flange Size | CF150/8" OD system flange | CF200/10" OD system flange | ||

| Substrate Heating | 800°C | |||

| Heater Element | Refractory metal module with Silicon Carbide Coated Graphite (SiCg) heating element | |||

| Flange to Cradle Distance | 200mm | |||

| Height adjustment (option) | 50mm | |||

| Fixed height shutter (option) | Includes extended bearing housing for 4" substrates | |||

| Thermocouple | Type K | |||

EpiCentre Power Supplies & Controllers

EpiCentre Controllers and Power Supplies

The EpiCentre range can be configured to allow the use of existing motor, temperature controller and heater power supplies. Where new equipment is required we offer complete solutions from a series of high quality, modular, control packages.

Substrate Rotation

EpiCentre stages with wafer sample rotation may be fitted with DC or stepper motors. The DC option is preferred for smooth, continuous rotation, however, if indexing or positioning of the substrate is required then a stepper motor should be selected.

Stepper Motors

The Programmable Stepper Motor Control Center (SMC series) provides a complete solution to substrate rotation. Supplied with its own WindowsTM based software, the interface is intuitive while providing a comprehensive array of control options. It may also be linked to an existing host controller via various inputs and outputs.

DC Motors

If DC motors are selected for the EpiCentre substrate spin system, then the rotation controller may be used. This unit is a 24VDC power supply providing speed control. A rear panel connector allows remote operation from a 0-10 volt programming signal. The unit is housed in a half rack, 3U enclosure and complies with CE regulations.

Axial Translation

For motorization of the various axial translations offered it is recommended that the customer uses either the Programmable Stepper Motor Control Center or the hand-held DC controller.

Temperature Controllers

For optimal stage heating and substrate temperature control the TC1 power supply with 3–term proportional temperature control is offered. The unit comprises a Eurotherm PID (Proportional, Integral and Derivative) temperature controller driving a Glassman high performance programmable DC power supply of suitable voltage / current rating to match the heater requirement.

The Glassman unit offers reliable, low-noise operation, resulting in low element stress and minimal EMC interference when performing RHEED measurements.

The TC1 is CE compliant and can be supplied with a range of features.