Silver Ag Evaporation Process Notes

Silver is a soft, lustrous element that belongs to the transition group of metals on the periodic table. It has a melting point of 962°C, a density of 10.5 g/cc, and vapor pressure of 10-4 Torr at 1,105°C. Silver has been used since ancient times in countless products. It is ductile, malleable, and the most electrically conductive of all metals. It is considered a precious metal and can be found in jewelry, solders, paints, and mirrors. It is evaporated under vacuum for the production of semiconductors, sensors, fuel cells, and optical coatings.

Silver Ag Specifications

| Material Type | Silver |

| Symbol | Ag |

| Atomic Weight | 107.8682 |

| Atomic Number | 47 |

| Color/Appearance | Silver, Metallic |

| Thermal Conductivity | 430 W/m.K |

| Melting Point (°C) | 962 |

| Coefficient of Thermal Expansion | 18.9 x 10-6/K |

| Theoretical Density (g/cc) | 10.5 |

| Sputter | DC |

| Max Power Density (Watts/Square Inch) | 100* |

| Type of Bond | Indium, Elastomer |

| Z Ratio | 0.529 |

| E-Beam | Excellent |

| Thermal Evaporation Techniques |

Boat: W Coil: Mo Basket: Ta, Mo Crucible: Al2O3, W |

| E-Beam Crucible Liner Material | FABMATE®, Tungsten, Molybdenum, Tantalum |

| Temp. (°C) for Given Vap. Press. (Torr) |

10-8: 847 10-6: 958 10-4: 1,105 |

* This is a recommendation based on our experience running these materials in KJLC guns. The ratings are based on unbonded targets and are material specific. Bonded targets should be run at lower powers to prevent bonding failures. Bonded targets should be run at 20 Watts/Square Inch or lower, depending on the material.

Z-Factors

Empirical Determination of Z-Factor

Unfortunately, Z Factor and Shear Modulus are not readily available for many materials. In this case, the Z-Factor can also be determined empirically using the following method:

- Deposit material until Crystal Life is near 50%, or near the end of life, whichever is sooner.

- Place a new substrate adjacent to the used quartz sensor.

- Set QCM Density to the calibrated value; Tooling to 100%

- Zero thickness

- Deposit approximately 1000 to 5000 A of material on the substrate.

- Use a profilometer or interferometer to measure the actual substrate film thickness.

- Adjust the Z Factor of the instrument until the correct thickness reading is shown.

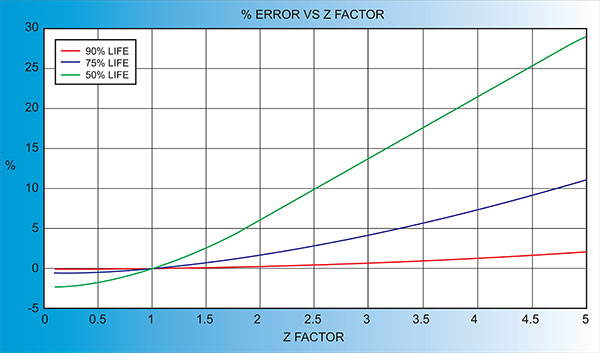

Another alternative is to change crystals frequently and ignore the error. The graph below shows the % Error in Rate/Thickness from using the wrong Z Factor. For a crystal with 90% life, the error is negligible for even large errors in the programmed versus actual Z Factor.