Molybdenum Oxide MoO3 Evaporation Process Notes

Molybdenum oxide is a chemical compound with a chemical formula of MoO3. It is white to pale yellow in color with a melting point of 795°C, a density of 4.69 g/cc, and a vapor pressure of 10-4 Torr at ~900°C. It is primarily used to manufacture pure molybdenum metal. It is evaporated under vacuum to make transparent electrodes for photovoltaic cells.

Molybdenum Oxide MoO3 Specifications

| Material Type | Molybdenum Oxide |

| Symbol | MoO3 |

| Color/Appearance | White to Pale Yellow, Crystalline Solid |

| Melting Point (°C) | 795 |

| Theoretical Density (g/cc) | 4.69 |

| Sputter | RF |

| Type of Bond | Indium, Elastomer |

| Z Ratio | **1.00 |

| Thermal Evaporation Techniques |

Boat: Mo Basket: Mo Crucible: Al2O3, BN |

| Temp. (°C) for Given Vap. Press. (Torr) | 10-4: ~900 |

| Comments | Slight oxygen loss. |

** The z-ratio is unknown. Therefore, we recommend using 1.00 or an experimentally determined value. Please click here for instructions on how to determine this value.

Z-Factors

Empirical Determination of Z-Factor

Unfortunately, Z Factor and Shear Modulus are not readily available for many materials. In this case, the Z-Factor can also be determined empirically using the following method:

- Deposit material until Crystal Life is near 50%, or near the end of life, whichever is sooner.

- Place a new substrate adjacent to the used quartz sensor.

- Set QCM Density to the calibrated value; Tooling to 100%

- Zero thickness

- Deposit approximately 1000 to 5000 A of material on the substrate.

- Use a profilometer or interferometer to measure the actual substrate film thickness.

- Adjust the Z Factor of the instrument until the correct thickness reading is shown.

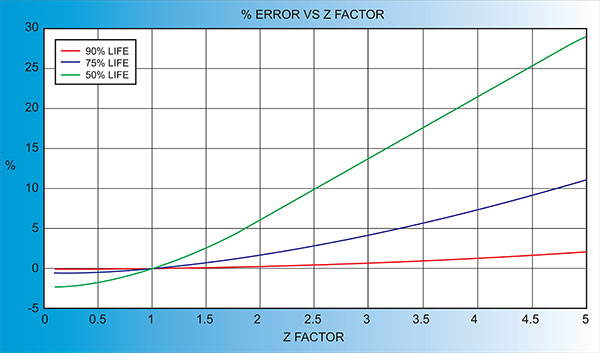

Another alternative is to change crystals frequently and ignore the error. The graph below shows the % Error in Rate/Thickness from using the wrong Z Factor. For a crystal with 90% life, the error is negligible for even large errors in the programmed versus actual Z Factor.