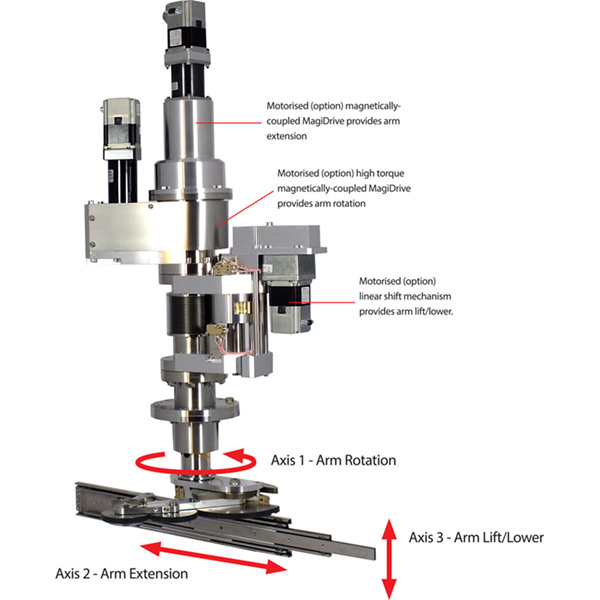

The 3-axis RTTA provides 360° rotation, 760mm linear extension and 50mm Z motion to provide arm lift and lower to aid sample transfer. Typically <1mm deflection at full arm extension with 10N load. Linear reproducibility of <0.2mm and rotational reproducibility of <0.2mm. Motorization options available.

Features

- 760mm extension

- Typically <1mm deflection at full extension under 10N load

- Rotational reproducibility <0.2mm

- Linear reproducibility <0.2mm

- Clean, UHV performance

- Competitively priced compared to conventional designs

The 3-axis RTTA provides a cost-effective radial distribution sample transfer solution for applications that require arm rotation, arm extension and arm lift and lower for sample transfer.

A high torque magnetically-coupled MagiDrive provides arm rotation to align with the desired chamber port. A second MagiDrive is used to drive the innovative telescopic mechanism to provide an arm extension of 760mm to transport the sample in and out of the desired satellite chamber. A linear shift mechanism is used to provide 50mm lift/lower of the sample arm for gravity based sample hand off, typically used on our MBE, sputtering and CVD sample manipulators and heating stages.

The 3-axis RTTA can be fully motorized using stepper or SMART motors. Alternatively the RTTA can be configured to accept any standard NEMA23 frame motor.

Specification Table

| Model | RTTA 3-Axis |

| Mounting Flange | CF100 152mm (6") OD CF |

| Min radial port flange size for arm | CF100 152mm (6") OD CF (Arm lift dependent on radial port ID) |

| Min radial port size and clear bore required for assembly installation | CF150 203mm (8") OD CF and 150mm bore |

| Rotation motion | Unlimited manual and +/-180° motorized |

| Minimum chamber ID | 630mm |

| Minimum chamber free height | 152mm |

| Arm lift motion stroke | 50mm (48mm if motorized) |

| Arm extension | 760mm |

| Arm extension from port of 630mm ID chamber | 688mm* |

| Arm stiffness at full extension | Typically <1mm deflection for 10N load |

| Rotational reproducibility | 0.2mm at full extension |

| Bakeout temperature | 250°C (with motors removed) |

* Contact us for detailed drawings, STEP files and installation guidance.